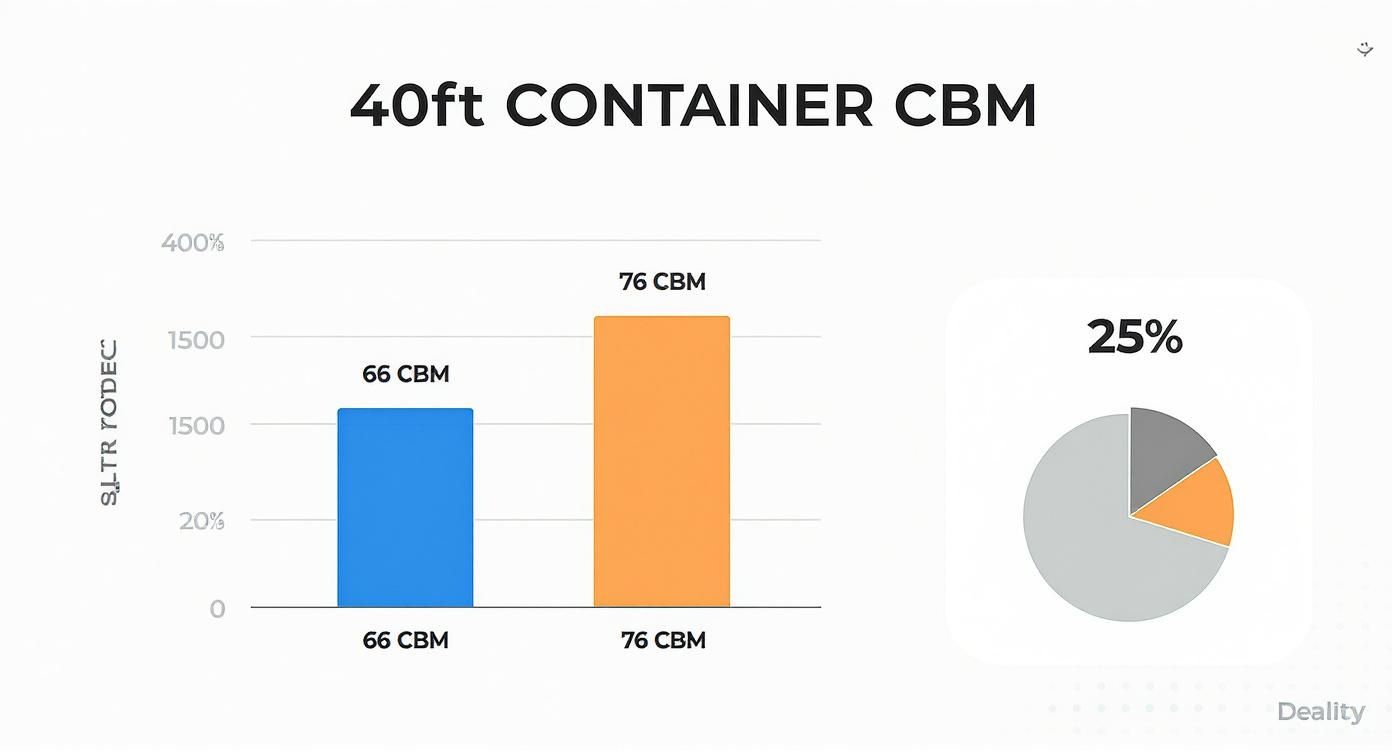

A standard 40-foot shipping container gives you roughly 66 to 67 cubic metres (CBM) of room to work with. If you opt for a 40-foot high cube container, that extra bit of height bumps your total space up to about 76 CBM.

That difference might not sound like much, but in the world of logistics, it can be the key to optimising your cargo and keeping costs in check.

Comparing Standard And High Cube 40ft Container CBM

When you're mapping out a shipment, getting the cubic metre capacity right is non-negotiable. It's the foundation of cost-effective logistics. The decision between a standard 40ft container and its high cube counterpart almost always boils down to the total volume of your goods.

They share the exact same length and width, but that extra foot of height in a high cube model makes a world of difference.

To put it in simple terms, here's a quick side-by-side look at their internal capacities.

Quick Summary of 40ft Container CBM

| Container Type | Internal Height (m) | Capacity (CBM) |

|---|---|---|

| Standard 40ft Container | ~2.39 m | ~66 CBM |

| High Cube 40ft Container | ~2.70 m | ~76 CBM |

This table lays out the essential figures you need at a glance.

That ~10 CBM difference is often the deciding factor. It could mean fitting in that last pallet, avoiding the need for a second container, and ultimately, saving a significant amount on your shipping bill.

Getting a firm grasp on these numbers right from the start gives you a solid foundation before we jump into the nitty-gritty of the calculations.

Getting to Grips with CBM

Before we jump into the hard numbers for a 40ft container, let's get a real feel for what CBM actually is. Think of Cubic Metres (CBM) as the currency of space in the shipping world. It’s not just an abstract number on a freight quote; it’s the metric that dictates how much you'll pay, particularly for Less than Container Load (LCL) shipments.

Imagine you're packing a big, empty room for storage. CBM is simply the total three-dimensional space your boxes and furniture take up. In logistics, that "room" is a shipping container, and your CBM calculation tells the carrier exactly how much of their valuable container space your cargo needs.

Why CBM Is More Than Just a Measurement

Nailing your CBM calculation is the cornerstone of efficient, cost-effective shipping. Even a small error can ripple outwards. If you underestimate your CBM, you might show up at the warehouse only to find your cargo won't fit, leading to frustrating delays and surprise fees. Overestimate, and you're essentially paying for air—space you didn't even use.

This is where things get interesting with a concept called chargeable weight. Carriers will look at the actual physical weight of your cargo and compare it to its volumetric weight (which is derived from its CBM). They'll charge you based on whichever figure is higher. This system ensures that light but bulky goods—think cotton balls or styrofoam—pay their fair share for the large amount of space they occupy.

CBM is the universal language for cargo volume. Getting it right means you can plan better, get accurate quotes, and dodge those nasty, unexpected port charges. It’s often the difference between a smooth-sailing shipment and a costly logistical nightmare.

Picturing the Space You Need

It helps to have a mental picture of what different volumes look like in the real world. To calculate CBM properly, you need to be able to visualise how length, width, and height combine to create usable space. For a helpful comparison, you can look at a UK storage unit size guide to see how different dimensions translate into practical storage capacity.

Understanding CBM is your first step to making smart shipping decisions. It empowers you to know whether a standard 40ft container with its ~66 CBM of space is enough, or if you should spring for the extra vertical room in a High Cube. With this foundation, you’re ready to dive into calculating this critical number for your own cargo.

How to Calculate Your Container CBM, Step by Step

Figuring out the cubic metre (CBM) for your cargo sounds a bit technical, but the reality is surprisingly simple. It all comes down to a basic formula that you can apply to anything, from a single carton to a full container load.

The CBM calculation at its core is:

CBM = Length (in metres) × Width (in metres) × Height (in metres)

This gives you the volume for one package. If you’re shipping a batch of identical items, just multiply that number by how many you have. Let’s walk through a real-world example to see how it works.

The CBM Formula in Action

Let’s say you need to ship 20 identical boxes. The first thing you need to do is measure one of them. The key here is to use metres, since CBM stands for cubic metres. If your tape measure is in centimetres, no problem—just divide each measurement by 100 to get it into metres.

Here's how you'd do it:

- Measure your box: Imagine its dimensions are 80 cm (Length) x 60 cm (Width) x 50 cm (Height).

- Convert to metres:

Length: 80 cm ÷ 100 = 0.8 m

- Width: 60 cm ÷ 100 = 0.6 m

- Height: 50 cm ÷ 100 = 0.5 m

- Calculate the CBM for a single box: 0.8 m × 0.6 m × 0.5 m = 0.24 CBM.

- Calculate your total CBM: 0.24 CBM per box × 20 boxes = 4.8 CBM.

That final number, 4.8 CBM, is what your freight forwarder needs. It’s what they’ll base their quote on and how they'll plan the space for your shipment. Getting this calculation right is the first, most important step to a smooth and accurately priced shipment.

For a more detailed walkthrough, feel free to check out our complete guide on how to calculate CBM.

A Quick Pro Tip: Always, always measure the outermost points of your cargo. That includes any bulges, handles, or odd bits sticking out. A few centimetres might not seem like a big deal on one box, but across a whole shipment, those small miscalculations can add up, leading to a space crunch or unexpected extra charges.

What About Multiple Box Sizes or Awkward Shapes?

So, what happens when your shipment isn't a neat stack of identical boxes? The process is just as straightforward. All you have to do is calculate the CBM for each group of different-sized boxes separately. Once you have the CBM for each group, just add them all together for your grand total.

For irregularly shaped items—think machinery, furniture, or anything that isn't a perfect cube—the trick is to measure it as if it were inside a box. Find the longest, widest, and tallest points and use those measurements for your L x W x H calculation. This method creates an "imaginary cube" around the item, ensuring you book enough room to fit it without any last-minute surprises.

If you’re dealing with a lot of mixed cargo, online tools can be a huge help. Using a cubic metre calculator can automate the conversions and sums for you, which seriously cuts down on the risk of human error. It’s a great way to make sure your packing plans are based on solid, accurate numbers.

Standard 40Ft Container CBM

Transport planners need clear CBM numbers to avoid surprise costs and loading hiccups. Breaking down the true interior volume of a 40Ft container helps you match your cargo precisely.

Inside a general-purpose box you’ll find dimensions of 12.03 m (length) × 2.35 m (width) × 2.39 m (height). On paper, that multiplies to 67.6 CBM, but beams, door frames and corner castings shave about 1–2% off the total, leaving roughly 66 CBM of true usable space.

- Overall Nominal Volume: 12.03 m × 2.35 m × 2.39 m = 67.6 CBM

- Usable Height Under Beams: ~2.33 m (–2.5%)

- Effective Internal Length Past Door: ~11.95 m (–0.7%)

Brands And Port Variations

Operators vary slightly on how they quote capacity, but most Chinese carriers like COSCO Shipping or China Shipping Container Lines stick to 66 CBM for standard GP models. At major ports—Shanghai, Ningbo and Shenzhen—that 66–67 CBM range is the norm. Forwarders in these hubs rarely see figures outside this band. Discover more insights about container specifications in China fields with ProChinaFreight.

“Container volumes have stayed stable since the 1990s under ISO rules, giving you a reliable baseline.”

Practical Planning Tips

When you’re loading odd shapes or bulky goods, a few simple checks can save headaches. Leave room for protective packing and unexpected snags by following these steps:

- Measure each item’s length, width and height before booking

- Subtract 2–3 cm for wrapping, dunnage or braces

- Factor in door swings and beam intrusions

Always verify the container’s certification plate for exact dimensions—sometimes you’ll find a 1 cm variation. This small margin prevents you from overbooking or leaving unused space.

For full details on exact dimensions and loading advice, check out our guide on 40ft container size specifications.

Proper planning not only maximises your CBM but also protects your cargo and cuts shipping costs.

The 40ft High Cube: Your Solution for Taller Cargo

Sometimes, a standard 40ft container just won’t do. If you're dealing with cargo that’s a bit too tall, bulky, or you simply need to cram more in, its taller sibling—the 40ft high cube container—is the perfect upgrade.

Think of it as the standard 40ft with an extra foot of headroom. This seemingly small change makes a huge difference, boosting the total volume from about 66 CBM to a much more generous 76 CBM. The internal height jumps from around 2.39 metres to 2.70 metres, while the length and width stay the same.

That extra 10 CBM isn't just a number on a spec sheet. It's real, usable space that can save you money and headaches.

Why That Extra Height Is a Game-Changer

That extra vertical space is a lifesaver for goods that are too tall for standard containers. We're talking about things like large machinery, construction materials, long pipes, or oversized crates that would otherwise require special (and more expensive) shipping arrangements.

It's also a smart move for businesses shipping lightweight but voluminous products. For goods like furniture, textiles, or palletised e-commerce inventory, the high cube often lets you fit what might have been two separate shipments into one. This efficiency means fewer containers, which directly translates to lower freight costs.

In China, the 40-foot high cube has become incredibly popular, especially for exporters sending oversized goods to Europe and North America. Its 76 CBM capacity is a major advantage, and by 2023, high cubes made up about 25% of all 40ft containers used in China's international trade. You can dig deeper into the 40-foot high cube's role in global shipping.

This isn't a niche trend; it's a major shift in shipping strategy. Chinese ports and container leasing companies have fully embraced this demand, making the 76 CBM high cube a common and easy-to-book option. For any shipper, choosing a high cube is often a strategic decision to get the most out of every shipment and keep supply chain costs in check.

Getting the Most Out of Your Container: Usable CBM and Smart Pallet Loading

The official capacity of a 40ft container—66 CBM for a standard or 76 CBM for a high cube—is what we call its nominal volume. But here’s something every experienced shipper knows: you never actually get to use all of it. The real-world, practical capacity is always going to be a bit less.

Think of it like trying to pack a suitcase. You know the suitcase's dimensions, but you can never fill every last nook and cranny. The zippers, the lining, and the awkward shapes of your clothes mean some space just can't be used. It's the same with a container. The corrugated walls, support beams, and the clearance needed for the doors all chip away at your workable area.

Understanding this difference between nominal and usable CBM is the key to loading efficiently. It forces you to stop thinking about a theoretical number and start focusing on how to best use the space you genuinely have.

This infographic gives a great visual breakdown of the CBM difference between a standard 40ft container and its high-cube cousin.

As you can see, that extra foot of height in a high-cube container can make a huge difference, especially when you're shipping bulky, oversized, or awkwardly shaped cargo.

How Pallets Affect Your Usable Space

For most shipments, pallets are the foundation of your load plan. But they also add another layer of complexity to the usable CBM puzzle. Gaps between pallets, the space needed for bracing materials, and imperfect stacking patterns can eat up your volume faster than you'd think.

So, how many pallets can you actually fit? Let's look at some real-world numbers.

- Standard Pallets (1.2m x 1.0m): On the floor of a 40ft container, you can typically load 20 to 21 of these pallets in a single layer. If your cargo is stackable, that number doubles to 40-42.

- Euro Pallets (1.2m x 0.8m): Their slightly smaller footprint means you can often squeeze in 23 to 24 Euro pallets per layer.

A crucial point to remember: the goal isn't just to cram in as many pallets as possible. It's about loading them safely and securely. Always factor in space for dunnage—like airbags, foam, or bracing—to stop your cargo from shifting around at sea. A secure load is a safe load.

If your shipment isn't big enough to justify a whole container, understanding pallet CBM is even more critical. You can learn more about this cost-effective method in our guide to Less than Container Load shipping. Getting these practical loading strategies right is how you truly maximise the value of every dollar you spend on freight.

Optimize Weight Limits And Packing Efficiency

Knowing the CBM of a 40ft container is just part of the puzzle. Each box also comes with a strict maximum payload—the total weight it can safely carry. Push past this threshold and you risk hefty fines, shipment delays and even safety hazards.

A standard 40ft container usually handles between 25,000 to 27,600 kg. That figure covers your goods, pallets and any dunnage you use for bracing. Always match your volume calculations against this weight cap.

The Clash Between Volume And Weight

Dense cargo—think machinery, metal components or stone tiles—can fill only half your container by volume but hit the weight ceiling. We call that “weighing out.”

On the flip side, bulky but light items like foam insulation or loose furnishings might pack every cubic metre before reaching the payload limit. That’s known as “cubing out.” A robust shipping plan checks for both scenarios.

For LCL (Less than Container Load) shipments, carriers compare your actual weight with the volumetric weight (derived from CBM). They’ll charge based on whichever number is higher—this is your chargeable weight.

Key Takeaway: Always calculate both total CBM and total weight. Your shipment only succeeds if it respects the container’s usable volume and its maximum payload.

Smart Packing For Maximum Efficiency

Packing smart isn’t just about squeezing in more; it’s about keeping the load stable and safe. An unbalanced container can tip or shift during transit, damaging goods and creating hazards at transfer points.

Follow these practical steps for a secure load:

- Distribute Weight Evenly: Heaviest items go on the floor, spread along the container’s length.

- Stack Strategically: Heavy boxes sit at the bottom, lighter ones above to avoid crush damage.

- Alternate Pallet Patterns: Turn pallets to interlock them, reducing gaps and boosting stability.

- Secure Everything: Fill voids with dunnage, straps or braces so nothing moves when the container rolls.

At Upfreights, we guide you through CBM assessments, payload checks and packing tactics. Whether you need an FCL or LCL quote, our experts will plan your shipment efficiently—door to door.