The standard 20 ft container's external dimensions are typically 20 feet long (6.06m), 8 feet wide (2.44m), and 8.5 feet high (2.59m). These measurements aren't just arbitrary; they form the bedrock of global shipping standards, making this container a true workhorse in international logistics.

Your Guide to 20 Ft Container Specifications

Getting to grips with the exact dimensions of a 20 ft container is fundamental for anyone involved in shipping. It's the key to smart cargo planning and keeping your costs in check. This simple steel box is so foundational that the industry uses it as a standard unit of measurement: the TEU (Twenty-foot Equivalent Unit).

This standardisation means a 20 ft container loaded in Shanghai will fit perfectly onto a truck in Rotterdam or a train in Chicago. Officially, the precise measurements are 6.058 metres (19.9 ft) long, 2.438 metres (8 ft) wide, and 2.591 metres (8.5 ft) high. Given that China is the world's epicentre for container shipping, understanding these specs is particularly vital for importers sourcing goods from the region.

20 ft Standard vs High-Cube Container At-a-Glance

While the standard "Dry Van" (DV) container is the most common variant you'll see, it's worth knowing about its taller sibling, the "High-Cube" (HC). The table below offers a quick side-by-side comparison to help you decide which one fits your cargo needs.

| Specification | 20 ft Standard Container (DV) | 20 ft High-Cube Container (HC) |

|---|---|---|

| External Height | 8.5 ft (2.59 m) | 9.5 ft (2.89 m) |

| Internal Height | ~7.8 ft (2.38 m) | ~8.8 ft (2.69 m) |

| Cubic Capacity | ~33 cubic metres | ~37 cubic metres |

| Primary Benefit | Standardised & widely available | Extra vertical space for tall cargo |

The main takeaway here is that the High-Cube gives you an extra foot of height. That might not sound like much, but it can be the deciding factor for fitting in taller machinery, double-stacked pallets, or bulky, awkwardly shaped items.

For a deeper dive into every measurement, from tare weight to door opening sizes, check out this complete guide to 20 ft container dimensions. Knowing these details inside and out is the best way to prevent costly mistakes and make sure you're getting the most out of every shipment.

A Detailed Breakdown of Container Measurements

While the quick-reference numbers are great for a ballpark estimate, getting your cargo planning right means digging a little deeper into the specific dimensions of a 20 ft container. These measurements aren't arbitrary; they're set by international standards to make sure a box loaded in Shanghai fits perfectly onto a truck in Rotterdam.

The external dimensions are what the shipping lines and transport companies care about most. These define the container's footprint. For a standard 20 ft dry container, you're looking at 20 feet long (6.058m), 8 feet wide (2.438m), and 8.5 feet high (2.591m). This uniformity is the secret sauce of global logistics, allowing containers to be stacked high on vessels or moved seamlessly between trains and trucks.

Exploring the Internal Usable Space

Now, for you—the person actually putting goods inside—it's the internal dimensions that really count. You have to remember that the container's structure eats into the total space. The corrugated steel walls, the ceiling, and the heavy-duty marine-grade plywood floor, which is typically about 1.1 inches (28 mm) thick, all reduce the usable area.

Because of this, the internal space is always a bit less than the external numbers suggest. For your load planning, the key figures you need are roughly:

- Internal Length: 19.3 ft (5.898m)

- Internal Width: 7.7 ft (2.352m)

- Internal Height: 7.8 ft (2.385m)

It’s this small but critical difference between the outside and inside that often catches new shippers out. A few centimetres can be the difference between your cargo fitting perfectly and a costly repacking job at the port.

The Role of ISO Standards and Tolerances

So, how is this all kept consistent? Every shipping container is built to strict specifications laid out by the International Organisation for Standardisation (ISO), specifically the ISO 668 standard. This document is the rulebook, defining everything from the precise external dimensions to the placement of corner castings and minimum strength requirements.

It's worth noting that ISO 668 does allow for tiny manufacturing tolerances. One container might be a few millimetres different from the next, but these variations are so small they never cause an issue with handling equipment or stacking.

This standardisation is what makes the entire global trade system work. It’s a guarantee that any ISO-compliant container can be handled by any ISO-compliant crane, forklift, or truck chassis, anywhere on the planet. For an importer, this means the dimension of 20 ft container you book in China will match the equipment waiting to unload it at its final destination, preventing any nasty, expensive surprises.

Understanding Container Weight and Volume Capacity

When you're looking at a shipping container, its physical size is only half the story. The real question for any shipper is: how much can I actually fit inside? This comes down to two critical factors: weight and volume. Getting a firm grip on these numbers is absolutely essential if you want to plan your cargo efficiently and steer clear of costly surprises down the line.

Every container has three key weight specifications that you need to know. You'll find these stamped right on the container's CSC (Convention for Safe Containers) plate, which is usually found on the outside of the doors. Trust me, ignoring these figures is not an option if you want a smooth, compliant shipment.

Defining Key Weight Metrics

Each of these weight figures tells a different part of the story, and it's vital not to mix them up. A simple mistake here can lead to overweight fines, or even your cargo being rejected at the port.

Let’s break them down:

- Tare Weight: Think of this as the empty weight of the container itself, before you've loaded a single thing. A standard 20 ft container typically has a tare weight of around 2,300 kg (5,071 lbs). Keep in mind that this can vary a bit depending on how the container was built—things like the steel thickness or the type of flooring can make a difference.

- Max Gross Weight: This is the absolute, all-in maximum weight allowed for the container and its contents combined. You cannot exceed this number. For a 20 ft container, this limit is usually somewhere between 24,000 kg (52,910 lbs) and 30,480 kg (67,200 lbs), based on its specific rating.

- Payload (or Net Weight): This is the number that matters most to you as a shipper. It tells you the maximum weight of the cargo you're allowed to load. To find it, you simply subtract the Tare Weight from the Max Gross Weight. This generally gives you a payload between 21,700 kg (47,839 lbs) and 28,180 kg (62,126 lbs).

Calculating Internal Volume Capacity

Weight is one side of the coin; volume is the other. The internal cubic capacity dictates how much physical space your goods can take up. A standard 20 ft container gives you about 33.2 cubic metres (CBM), which is the same as 1,172 cubic feet, of usable space inside.

A constant puzzle in logistics is figuring out if your cargo will "weigh out" before it "cubes out." In other words, will you hit the maximum weight limit before you run out of space, or will you fill the entire container before you get anywhere near the weight limit?

For instance, if you're shipping something dense like steel bars, you’ll likely hit the payload limit with the container still looking half-empty. On the flip side, a shipment of light, bulky goods like styrofoam or unassembled furniture will fill up every last inch of space while being nowhere near the maximum weight. Nailing this calculation is key, and using tools like a sea freight cost calculator can help you see how these different factors play into your final shipping costs.

Door Opening Dimensions and Loading Accessibility

All that internal space in a 20 ft container doesn't mean much if you can't get your cargo through the doors. This is a crucial detail that many shippers, especially those new to the game, tend to overlook. The door opening is always a bit smaller than the internal width and height because of the container's heavy-duty steel frame and the thick rubber seals that keep it weathertight.

For a standard 20-foot container, you're typically working with a door opening of about:

- Width: 7.6 feet (2.338 m)

- Height: 7.5 feet (2.280 m)

This slight reduction from the internal dimensions creates a bottleneck you absolutely must plan for. Ignoring it can cause some serious headaches at the loading bay, from having to break down pallets on the spot to discovering a piece of machinery simply won't fit, leading to delays and extra costs.

Practical Loading Considerations

The door opening directly dictates your entire loading strategy, particularly when you're using equipment like forklifts. A forklift needs clearance not just for the cargo on its forks but also for its mast and the overhead guard. A classic mistake is to measure the cargo alone, completely forgetting to factor in the pallet's height and the room the forklift needs to manoeuvre safely.

As a rule of thumb, always leave a buffer of a few centimetres around your largest piece of cargo. This little bit of wiggle room accounts for any slight shifting during loading and prevents scrapes and damage to both your goods and the container's door seals.

Think about it this way: a crate that's exactly 2.33 metres wide might fit on paper, but it leaves zero margin for error. If the forklift operator approaches at a slight angle, the crate could easily get jammed, damaging the item, the container, or both. Proper planning, based on the actual door dimensions, is the key to a smooth, efficient, and damage-free loading process.

How Many Pallets Fit in a 20 ft Container

Knowing the raw dimensions of a 20 ft container is just the start. The real-world challenge is figuring out how your specific cargo will actually fit inside. For most shippers, this boils down to one critical question: how many pallets can I load? The answer directly impacts your cost per unit and overall shipping efficiency.

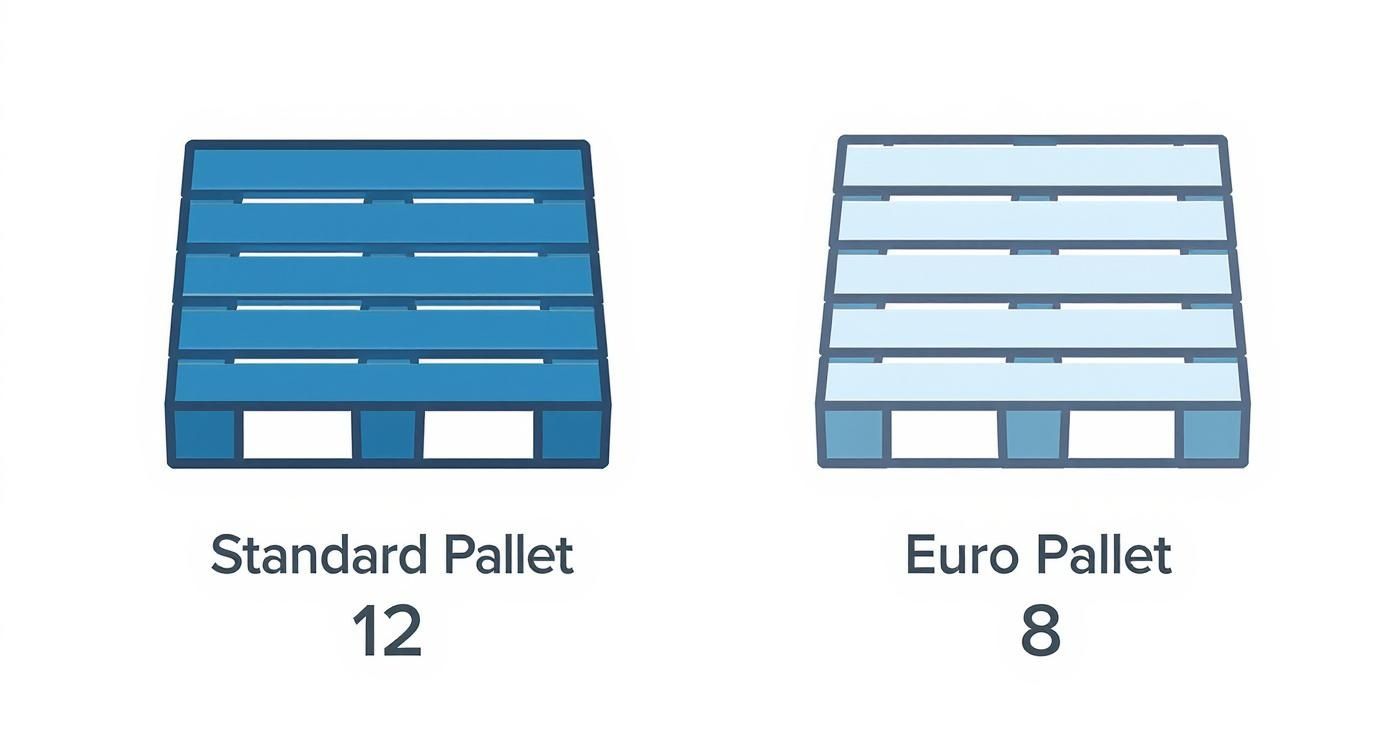

It all comes down to the type of pallet you're using. In global logistics, the two most common footprints are the Standard pallet and the Euro-pallet. Their different sizes mean they require completely different loading patterns to make the most of the container's floor space. Wasted space is wasted money, so getting this right is non-negotiable.

Loading Standard Pallets vs. Euro Pallets

The way you arrange pallets can make a huge difference in your total count. To truly maximise the space and prevent any issues during transit, you need a solid grasp of the various shipping pallet dimensions and how they interact. A small tweak in your loading plan can be the difference between getting everything into one container or needing to book a second.

A well-packed container is also a safer container. Intelligent stowage improves stability during transit, dramatically cutting the risk of cargo shifting and getting damaged.

So, how many can you typically fit on a single floor layer of a standard 20 ft container? Here’s a quick breakdown:

- Standard Pallets (1.2m x 1.0m): You can generally fit 9 to 10 of these. The best layouts usually involve turning some pallets 90 degrees to fit them together like a puzzle, minimising empty gaps.

- Euro-pallets (1.2m x 0.8m): Thanks to their slightly smaller width, you can comfortably load 11 Euro-pallets. This efficient fit makes them a go-to choice for shipments moving within or to Europe.

Pallet Loading Capacity for a 20 ft Container

To give you a clearer picture, this table outlines the typical number of pallets you can load onto a single floor layer. Remember, this assumes an optimal loading pattern is used.

| Pallet Type | Pallet Dimensions (L x W) | Typical Quantity (Single Layer) |

|---|---|---|

| Standard Pallet | 1.2 m x 1.0 m | 9 - 10 |

| Euro-pallet | 1.2 m x 0.8 m | 11 |

These numbers represent the best-case scenario for maximising floor space. Your actual count may vary slightly based on how the pallets are packed and loaded.

Single vs. Double Stacking Considerations

Of course, the floor is only one part of the equation. Double-stacking your pallets can effectively double your container's capacity, but you can't just pile them up without a second thought. This strategy depends entirely on the nature of your cargo and the strength of your packaging.

Before you even consider double-stacking, you have to weigh three critical factors:

- Cargo Weight: The total payload must stay under the container's maximum gross weight. If you're shipping heavy goods, you'll likely "weigh out" long before you "cube out," making stacking impossible.

- Cargo Height: The total height of two stacked pallets can't exceed the container's internal height, which is roughly 2.38 metres. Don't forget to account for the pallet height itself!

- Cargo Durability: This is the big one. The goods on the bottom layer need to be sturdy enough to handle the full weight of the pallets on top without getting crushed or damaged.

For businesses shipping lighter, robust products, learning to stack properly is a key component of smart consolidation. You can explore more great freight consolidation strategies to find other ways to drive down your shipping costs.

Key Shipping Considerations for Importers

Knowing the dimensions of a 20 ft container is one thing, but translating those numbers into smart, cost-effective shipping decisions is what really counts for importers. In the world of global logistics, the 20 ft container isn't just a box—it's the TEU (Twenty-foot Equivalent Unit). This is the bedrock metric used everywhere from Shanghai to Rotterdam to measure a vessel's capacity and, crucially, to calculate your freight rates.

This standardisation has a direct impact on your bottom line. When you're ready to book a shipment, you're faced with a strategic choice that hinges on your cargo's specific volume and weight. The decision usually boils down to one of three options, each with its own cost structure.

FCL vs LCL and Container Sizing

Getting your shipping method right is absolutely vital for keeping your logistics budget in check. The choice you make will depend entirely on whether your cargo can fill a container or if sharing space makes more financial sense.

- Full Container Load (FCL): This is where you book an entire 20 ft or 40 ft container just for your goods. It’s the go-to option for larger shipments—think anything over 15 CBM—because it typically offers a better cost-per-unit and your cargo remains sealed and secure from origin to destination.

- Less than Container Load (LCL): Your goods are consolidated into a shared container alongside cargo from other shippers. LCL is perfect for smaller shipments that don’t come close to filling a full container. The per-CBM rate is higher, but you only pay for the space you use.

- Choosing a 40 ft Container: If your cargo volume is just a bit too much for a 20 ft container, don't automatically book two. A 40 ft FCL often provides double the space for significantly less than double the price, delivering fantastic economies of scale.

The infographic below gives you a great visual on how different pallet types fit inside a standard 20 ft container, a critical piece of the puzzle for FCL planning.

As you can see, the layout for Euro-pallets is slightly more efficient, allowing you to pack the container floor more tightly compared to Standard pallets.

Navigating Global Trade Dynamics

It's not all about simple volume calculations. The availability and cost of 20 ft containers are massively influenced by the ebb and flow of global trade. Market conditions can turn on a dime, affecting everything from freight rates to whether you can even get a container in the first place. For businesses importing from China, keeping your finger on the pulse is non-negotiable for making timely and cost-effective bookings.

Recent data shows just how much trade volumes, measured in TEUs, can fluctuate in response to tariffs, geopolitical events, and global crises. For example, after the U.S. imposed 145% tariffs on certain Chinese imports in April 2025, the number of 20ft containers shipped from China to the U.S. plunged from 81,448 to 44,807 TEUs in a matter of weeks. It’s a stark reminder of how trade policy directly shapes container demand. You can discover more insights about how tariffs affect shipping volumes on NAM.org.

Importer's Tip: When freight costs are soaring or containers are scarce, it can be wise to consider LCL even for shipments that are borderline FCL size. Yes, the per-CBM rate might be higher, but it can offer much-needed flexibility and help you sidestep the premium pricing that comes with FCL during peak season.

Successfully managing these variables requires a real understanding of the market. Working with an experienced freight forwarder can give you the invaluable guidance needed to pick the right shipping strategy every time. To get a better handle on these complexities, take a look at our detailed guide on how to arrange sea freight from China.

Your 20 ft Container Questions Answered

To wrap things up, let's tackle some of the most common, practical questions people ask when they're planning a shipment. Getting these finer details right, from the container's construction to its strength, can make all the difference.

What Are 20 ft Containers Made Of?

Shipping containers are built tough for a reason. Their main component is a special type of high-strength steel called Corten steel, sometimes known as weathering steel. This isn't your average steel; it's specifically designed to resist corrosion from the atmosphere and handle immense structural stress.

This robust build is what allows them to survive the harsh conditions at sea—think constant saltwater spray and being stacked high on container ships. It’s this durability that gives shippers confidence that their valuable cargo is protected, journey after journey.

How Strong Is The Floor In A 20 ft Container?

The floor of a 20 ft container is surprisingly strong, engineered to handle not just heavy cargo but also the machinery used to load it, like forklifts.

Typically, you'll find it's made from 1.1-inch (28 mm) thick marine-grade plywood. This wood is treated to ward off moisture and pests, and it's rigorously tested to meet specific ISO load-bearing standards. This makes it perfectly suitable for dense, heavy items.

A quick word of advice: While the floor is incredibly strong, you still need to distribute the weight of your cargo evenly. Piling a very heavy load onto one small spot can lead to damage. Always plan your stowage to spread the weight across the entire floor.

Can You Get A 20 ft Container In Different Heights?

Yes, absolutely. The standard 20 ft container has an external height of 8.5 feet (2.59 m), which is what most people are familiar with. But there's another option: the "High-Cube" (HC) version.

A 20 ft High-Cube container gives you an extra foot of headroom, bringing its external height up to 9.5 feet (2.89 m). This variant is a game-changer if you're shipping tall goods or want to pack in more volume with light, stackable cargo.

Article created using Outrank