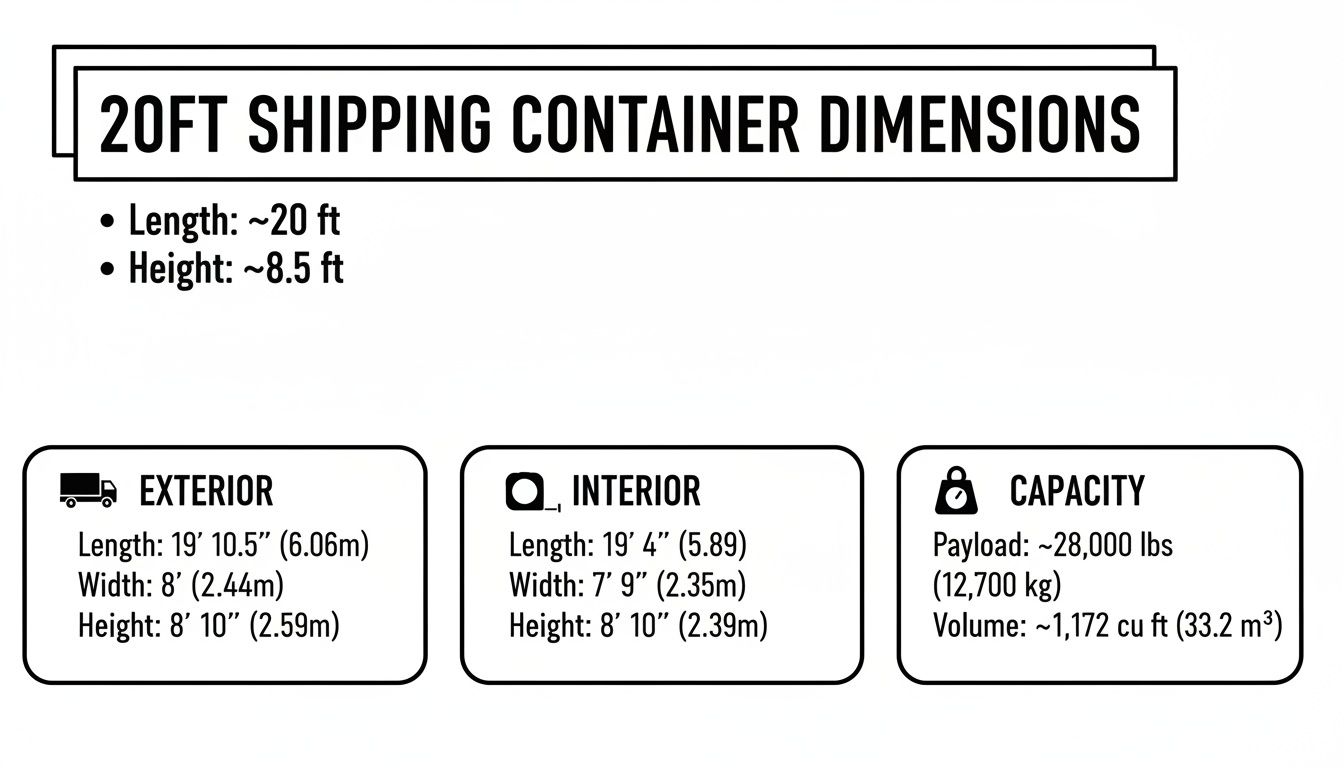

When you're dealing with international freight, the standard 20-foot container is the workhorse of the industry. On the outside, you're looking at a box that's roughly 20 ft long, 8 ft wide, and 8.5 ft high. These numbers are more than just trivia; they are the starting point for every decision you'll make, from how you pack your goods to how your shipment will be moved.

Getting these core specifications right is the first step to making your shipping process smooth and predictable.

Your Essential 20ft Container Dimensions Guide

In global trade, precision is everything. For anyone shipping goods, the dimensions of a 20ft container are fundamental. They dictate how you plan your cargo layout, calculate your costs, and ensure your shipment moves seamlessly across ships, trains, and trucks. This guide cuts straight to the chase, giving you the essential specs you need.

The visual below gives you a quick, at-a-glance summary of the most important measurements, breaking down the external, internal, and capacity details.

It’s a great way to see the small but critical differences between the container's outer size and the actual usable space inside—a key factor for your payload.

Detailed Specifications Table

For those who need the exact figures, here is a detailed breakdown. This table provides all the critical measurements for a standard 20ft dry container, with both metric and imperial units for easy reference.

| Specification | Metric (metres/kg) | Imperial (feet/lbs) |

|---|---|---|

| Exterior Length | 6.058 m | 19 ft 10.5 in |

| Exterior Width | 2.438 m | 8 ft 0 in |

| Exterior Height | 2.591 m | 8 ft 6 in |

| Interior Length | 5.898 m | 19 ft 4 in |

| Interior Width | 2.352 m | 7 ft 9 in |

| Interior Height | 2.393 m | 7 ft 10 in |

| Door Width | 2.340 m | 7 ft 8 in |

| Door Height | 2.280 m | 7 ft 6 in |

| Cubic Capacity | 33.2 m³ | 1,172 cu ft |

| Tare Weight (Empty) | 2,200 kg | 4,850 lbs |

| Maximum Payload | 21,700 kg | 47,900 lbs |

| Maximum Gross Weight | 24,000 kg | 52,910 lbs |

These precise numbers are what you'll use for official documentation and carrier bookings. For more information, you can explore detailed shipping container specifications on ProChinaFreight.

Pro Tip: Always calculate your cargo space using the internal dimensions. It’s a common mistake to forget about the thickness of the container walls, which reduces the usable space. Planning with the internal figures ensures everything will actually fit.

Understanding Exterior vs. Interior Container Dimensions

When you're looking at a spec sheet, it's easy to see the numbers for a 20-foot container's dimensions. But what do those figures actually mean for your shipment? Getting this right is about more than just numbers; it’s about understanding the difference between the outside shell and the actual, usable space inside. This distinction is what makes or breaks a successful loading plan.

Let’s start with the outside. The exterior dimensions of a container are governed by strict standards from the International Organization for Standardization (ISO). For a standard 20-foot container, you're looking at 6.058m long, 2.438m wide, and 2.591m high.

This standardisation is the quiet genius behind global trade. It’s why a container loaded in China can be seamlessly lifted onto a lorry in the UK, a train in Germany, or a vessel bound for Canada without ever being unpacked. It’s the key to intermodal transport.

Maximising Your Usable Internal Space

Step inside, though, and it’s a different story. The interior dimensions are what really count for planning your cargo layout. Unsurprisingly, they are always smaller than the exterior. A standard 20-foot container gives you roughly 5.898m in length, 2.352m in width, and 2.393m in height to work with.

So, where does that space go? Several key structural features eat into the internal volume:

- Corrugated Walls: Those signature grooved steel walls provide essential strength, but they also take up a few crucial centimetres on all sides.

- Flooring: The container floor isn't just a thin sheet of metal. It's typically thick, marine-grade plywood laid over steel cross-members, which raises the base level.

- Ceiling Beams: The roof structure also has support beams that slightly reduce the total clearance from floor to ceiling.

Overlooking these small reductions is a classic rookie mistake. I’ve seen shippers measure their cargo against the external specs, only to discover at the last minute that their crates are a couple of centimetres too wide or tall to fit inside. It's a costly and completely avoidable headache.

Expert Tip: Always, always base your cargo planning on the internal dimensions. This simple rule ensures every pallet, box, and piece of machinery fits perfectly, saving you from the stress and expense of last-minute repacking at the port.

The Door Opening: Your Final Bottleneck

Even with a perfect internal plan, your cargo is useless if you can't get it through the door. The door opening is the narrowest point of the entire container and acts as the final gatekeeper for any large or awkwardly shaped items.

On a standard 20-foot container, the door opening is typically 2.340m wide and 2.280m high. Notice that this is slightly less than the internal width and height. When you're loading heavy machinery or using a forklift to slide in pallets, these are the most important numbers you have.

Always factor in a few centimetres of wiggle room on all sides. This protects both your goods and the container from scrapes and damage during loading. A solid grasp of these three distinct sets of measurements—exterior, interior, and door opening—is the foundation of any efficient, error-free shipment.

When you're shipping goods, the physical size of a 20-foot container is just one piece of the puzzle. Understanding its weight limits and payload capacity is absolutely crucial for a smooth, legal, and cost-effective shipment. Get these figures wrong, and you could be looking at serious penalties, frustrating delays, or even dangerous accidents.

You'll need to get familiar with three core terms: Tare Weight, Payload, and Gross Weight. Each one has a specific meaning and plays a vital role in planning your logistics.

Getting the Terminology Straight

To load your container efficiently, you first have to know the difference between these key weight specs. They all build on each other to give you the total weight that carriers and port authorities will be checking.

- Tare Weight: Think of this as the container's empty weight. It’s the mass of the steel box itself—walls, floor, and doors included—which typically comes in at around 2,200 kg (4,850 lbs).

- Payload (or Net Weight): This is the most important number for you as a shipper. It’s the maximum weight of the actual cargo you are allowed to load inside. For a standard 20-foot container, the payload is usually capped at 21,700 kg (47,900 lbs).

- Gross Weight (or MGW): This is the big one—the total combined weight of the container and your cargo (Tare Weight + Payload). The maximum gross weight for a 20ft container is generally 24,000 kg (52,910 lbs).

These aren't just suggestions; they are hard limits enforced across the globe. Accurately estimating your costs based on both weight and dimensions is fundamental to managing container freight. For a closer look at how these factors influence your budget, it's worth learning about mastering shipping quote calculators for accurate freight rates.

Why These Weight Limits Are a Big Deal

Sticking to these weight limits is not optional. Overloading a container creates a massive safety hazard, as it can cause the container's structure to fail when being lifted by a crane or while stacked on a ship navigating rough seas. Beyond the safety risks, there are serious legal and financial penalties.

Under the SOLAS (Safety of Life at Sea) convention, every container must have a Verified Gross Mass (VGM) certificate before it can be loaded onto a ship. If your VGM is wrong, your container will likely be rejected at the port, leading to expensive delays and demurrage charges.

What's more, the weight limits on the road can be even lower than the container's maximum payload. A container headed for an inland destination in the US, for instance, might have to comply with stricter road weight regulations than what was allowed for the ocean voyage. As the shipper, it's your responsibility to plan for the entire journey, not just the time at sea. China's shipping statistics really drive this home, showing how these rules impact port traffic. New post-2025 regulations are doubling down on even weight distribution to meet SOLAS-VGM standards—a change that has already been shown to cut demurrage by 25% for compliant FCL loads. You can read more about China's port traffic and containerised shipping on data.worldbank.org.

Pallet Capacity: How Many Pallets Fit in a 20ft Container?

Knowing the raw internal 20 foot container dimensions is just the start. To really get your money's worth, you need to think strategically about how you load your pallets. Packing them in efficiently doesn't just save you on shipping costs; it also keeps your cargo stable and secure all the way to its destination.

The whole game comes down to matching your pallet type with the best loading pattern. The two workhorses of international shipping are the Standard pallet and the Euro pallet, and their different sizes dramatically change how they fit inside a container.

Standard Pallets vs. Euro Pallets

Those few centimetres of difference between a Standard pallet and a Euro pallet might not seem like much, but they have a big impact on your total load. Standard pallets are a bit larger, so you'll fit fewer of them. The slightly more compact Euro pallet, on the other hand, lets you pack things in a little tighter.

- Standard Pallets: These measure 1.2m x 1m. You can typically fit 10 of these on the floor of a 20ft container. The go-to method is to arrange them in two rows, alternating their orientation to make the most of the space.

- Euro Pallets (EUR-pallets): Measuring 1.2m x 0.8m, their slimmer profile allows for a more efficient layout. You can usually get 11 Euro pallets into a standard 20ft container.

It's crucial to remember that these numbers are for a single, non-stackable layer. If your goods are light and stable enough to be stacked, you could potentially double these figures. However, that all depends on the height and integrity of your cargo.

The vast majority of containers—over 95%—are built in China, where it's common practice for exporters to load either 10 Standard pallets or 11 Euro pallets to fill the container's 33 CBM capacity. This approach works particularly well for lighter goods like textiles, where you often hit the cubic capacity limit long before the weight limit.

Crucial Tip: Don't forget to account for cargo overhang! If your boxes or goods stick out beyond the pallet edges, it will reduce the number of pallets you can fit. Always plan for a few centimetres of buffer space between pallets and between the pallets and the container walls. This small gap prevents damage during loading and transit.

20ft Container Pallet Loading Configurations

To get a clearer picture, here’s a quick breakdown of how each pallet type fits and the best way to load them.

| Pallet Type | Dimensions | Maximum Quantity (Single Layer) | Loading Pattern Notes |

|---|---|---|---|

| Standard Pallet | 1.2m x 1.0m | 10 pallets | Best loaded in two rows with alternating orientations to maximise floor space and create a tight fit. |

| Euro Pallet (EUR) | 1.2m x 0.8m | 11 pallets | The "pinwheel" pattern is highly effective, where pallets are arranged in alternating lengthwise and widthwise positions. |

Using the right pattern is about more than just fitting things in; it’s about safety. A well-executed pinwheel pattern, for example, creates an interlocking block that significantly reduces movement and shifting during a rough sea journey, protecting your goods.

Optimising Your Loading Plan

Simply knowing the maximum pallet count isn't enough—you need a solid loading plan. A good plan prevents last-minute headaches at the port and ensures you're not paying for empty space.

The foundation of any successful loading strategy is an accurate calculation of your cargo's total volume. To get this right, you'll need to know your CBM. For a detailed walkthrough, check out our guide on how to calculate CBM for your shipment.

Exploring the Different Types of 20ft Containers

The standard dry van might be the workhorse of global shipping, but the world of 20-foot containers is far more diverse. When your cargo isn't a standard size or has special requirements, picking the right container variant is crucial for a safe and efficient journey. Each specialised type is engineered to solve a specific logistics puzzle.

Getting this choice right from the start helps you avoid costly errors. You don't want to find out your temperature-sensitive goods were loaded into a standard container, or that your machinery is just a few inches too tall for a conventional unit. While the exterior dimensions are usually kept standard for transport compatibility, the internal space and features can change dramatically.

High Cube and Refrigerated Containers

Got cargo that's tall but not especially heavy? The High Cube (HC) container is the simple answer. A 20ft HC isn't as common as its 40ft big brother, but it gives you an extra foot of vertical space. This is perfect for those bulky, lightweight items like furniture or large equipment that just won't clear the standard 8.5-foot height.

On the other hand, Refrigerated containers, or 'reefers', are built for anything that needs to stay cool, like food or pharmaceuticals. Their internal dimensions are noticeably smaller than a standard 20ft box. This is because the thick insulation and the refrigeration unit itself eat into the available space, reducing both the cubic capacity and the maximum payload—a necessary trade-off for climate control.

Open Top and Flat Rack Containers

Some cargo just won't fit through the doors. That’s where Open Top and Flat Rack containers really prove their worth.

- Open Top Containers: These have a removable tarpaulin roof instead of a solid steel one. This design is a lifesaver for oversized cargo, like tall machinery or massive logs, which can be loaded in from above with a crane.

- Flat Rack Containers: These take it a step further. They have no roof and no side walls, and some even have ends that collapse. Think of them as a reinforced floor built to handle extremely heavy or oddly-shaped items like vehicles, boats, or big industrial parts.

Expert Insight: When you're using a specialised container like an Open Top or Flat Rack, remember that securing the cargo is far more complex. Lashing and dunnage become absolutely critical. Always work with your freight forwarder to make sure your goods are properly braced for the journey.

While the 20ft container is incredibly versatile, some shipments just need more room. To see how it stacks up against its larger counterpart, take a look at our complete guide to 40 ft container dimensions in feet.

Practical Loading Strategies for Importers

Knowing the technical 20 foot container dimensions is one thing, but actually putting that knowledge to work for a perfect load is another beast entirely. Getting your loading strategy right is a science that directly hits your bottom line—it keeps your cargo safe, squeezes the most value out of every cubic metre, and helps you sidestep expensive mistakes. It all starts with a solid plan that accounts for the weight, balance, and specific nature of your goods.

The golden rule here is even weight distribution. If you stack all your heavy items on one side or cram them at one end, you’re creating a recipe for disaster. An unbalanced container can become dangerously unstable on the road or at sea. Always spread the heaviest cargo evenly across the container floor to establish a low, solid centre of gravity. Once that foundation is set, you can pack lighter goods on top and use them to fill in the gaps.

Securing Your Cargo Effectively

Once everything is inside, your next job is to make sure it stays put. The motion of a container ship is no joke; constant vibration and swaying can turn unsecured cargo into a wrecking ball. This is where materials like dunnage, airbags, and lashing straps become your best friends. Use them to brace your items firmly against the container walls and each other, leaving no room for movement.

Key Takeaway: A well-secured load is a safe load. Spending a little on proper dunnage and bracing is a smart investment, and it’s always cheaper than replacing damaged products or dealing with the fallout from a major load shift.

Remember, proper securing prevents a domino effect. If one box starts to slide, it can take everything else with it, leading to catastrophic losses.

Choosing Between FCL and LCL Shipments

How you plan to load your cargo often dictates whether you should book a Full Container Load (FCL) or a Less than Container Load (LCL) shipment. If your goods will fill most of a 20ft container—think 15 CBM or more—then booking an FCL is almost always the smarter, more cost-effective move. You get the whole container to yourself, which means your cargo is handled less and isn't exposed to potential damage from other shippers' goods.

On the other hand, if you're only shipping a small volume, LCL is the way to go. Your freight gets consolidated with cargo from other importers to fill a shared container. It’s a great way to save money on smaller shipments, but it means your goods must be exceptionally well-packed and clearly labelled to handle being loaded alongside other items and processed at multiple touchpoints.

Making the right call here is crucial. To get a better handle on the pros and cons, check out our detailed guide comparing FCL and LCL shipping services. Ultimately, this decision loops right back to your cargo's dimensions and weight, proving just how vital a deep understanding of container specs is for shipping smarter.

Frequently Asked Questions About 20ft Containers

When you're dealing with the specifics of a 20-foot container, a lot of practical questions can pop up. Let's tackle some of the most common ones that shippers ask, so you can plan your logistics more effectively and sidestep any common mistakes.

What Is the Actual Usable Volume of a 20ft Container?

The spec sheet might say a 20ft container has a volume of around 33 cubic metres (CBM), but you'll never actually get that much in. In the real world, you're looking at a usable space closer to 28 to 30 CBM.

Why the difference? Perfect, wall-to-wall packing is just a myth. You always lose some space because of the pallets themselves, any awkwardly shaped items, and the dunnage you need to use to stop everything from shifting around on its journey.

Should I Choose a 20ft or 40ft Container?

This really comes down to what you're shipping. A 20ft container is your best bet for heavy, dense cargo. Think things like machinery, metals, or bottled drinks. You'll probably hit the maximum weight limit long before you run out of physical space.

On the other hand, if your goods are light but take up a lot of room, go for a 40ft container. It's the right choice for items like furniture, clothing, or plastic goods, where you need the volume but aren't likely to get anywhere near the weight limit.

What Does TEU Mean in Relation to a 20ft Container?

TEU stands for 'Twenty-foot Equivalent Unit'. It's the go-to unit of measurement for cargo capacity across the entire shipping industry.

It's simple: a standard 20ft container is exactly one TEU. That means a 40ft container counts as two TEUs. You'll see this metric used for everything from describing a container ship's size to a port's annual traffic volume.

Key Insight: Grasping the concept of TEUs gives you a sense of the scale of global trade. When you hear a vessel has a capacity of 10,000 TEUs, you know it can carry a massive 10,000 standard 20-foot containers.

Of course, getting the most out of your container space is only one part of the puzzle. Importers also have to keep an eye on the wider logistics picture, which includes understanding things like the latest in trucking insurance and how it affects their business.

Are the Dimensions of a 20ft Refrigerated Container the Same?

No, they're definitely not the same on the inside. A 20ft refrigerated container, often called a 'reefer', has the exact same external dimensions as a standard dry container. This is crucial for making sure it fits on ships, trains, and trucks just like any other box.

Internally, however, it's a different story. The walls, floor, and ceiling are much thicker to house all the insulation. Plus, the refrigeration unit takes up a chunk of space at one end. All this means the internal length, width, and height are smaller, leading to less usable volume and a lower payload capacity.