When you're planning a shipment, the first numbers you'll look at are usually the container's external dimensions. For a standard 40 ft container, that's 40 feet long, 8 feet wide, and 8 feet 6 inches tall.

But as any experienced shipper knows, it's the internal space that really counts. Those external figures don't tell you how much you can actually fit inside, especially once you account for the extra foot of height you get with a high-cube variant. Getting these precise measurements right from the start is absolutely fundamental to efficient freight planning.

Your Quick Reference Guide to 40 Ft Container Dimensions

This section is designed to give you a clear, no-nonsense breakdown of the most critical 40 ft container dimensions in feet. We've laid out all the essential external, internal, and door opening measurements for both the standard (GP) and high-cube (HC) containers to make your logistics planning easier. Use this as your go-to reference for accurate freight calculations—it’ll help ensure your cargo fits just right and you avoid any costly surprises down the line.

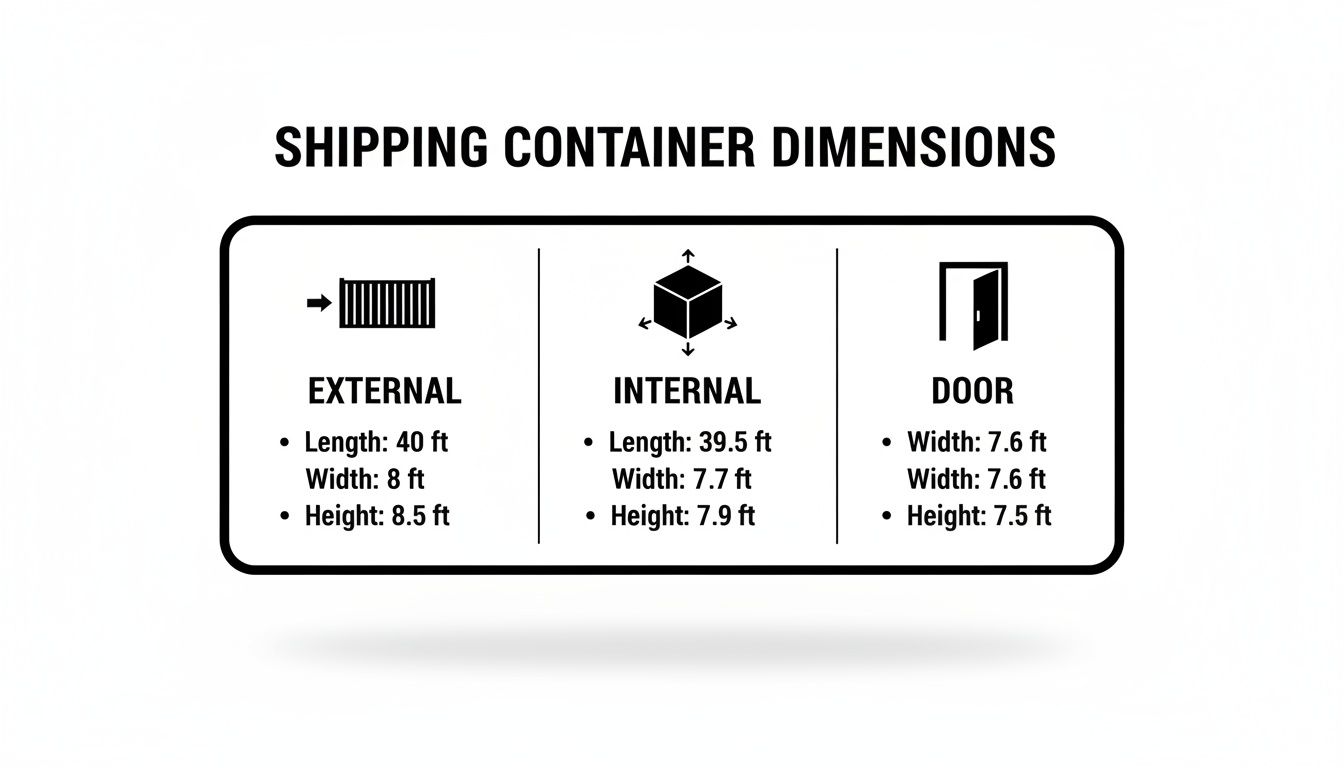

Here’s a great visual summary of the key differences you need to be aware of.

As you can see, while the outside measurements are standardized for transport infrastructure like ships and cranes, it's the internal usable space and the door clearance that are the truly crucial figures for anyone actually loading cargo.

40 Ft Container Dimensions at a Glance (Standard vs High-Cube)

To make things even simpler, here's a direct comparison of the most important dimensions. This table should help you quickly decide which container type is the right fit for your goods.

| Specification | Standard 40 Ft Container (GP) | 40 Ft High-Cube Container (HC) |

|---|---|---|

| External Height | 8 ft 6 in | 9 ft 6 in |

| Internal Height | 7 ft 10 in | 8 ft 10 in |

| Door Opening Height | 7 ft 5 in | 8 ft 5 in |

| External Length | 40 ft | 40 ft |

| Internal Length | 39 ft 5 in | 39 ft 5 in |

| External Width | 8 ft | 8 ft |

| Internal Width | 7 ft 8 in | 7 ft 8 in |

| Door Opening Width | 7 ft 8 in | 7 ft 8 in |

The key takeaway here is that extra foot of height in a high-cube. While it might not seem like much, it can be the difference between fitting that last pallet tier and having to book another container.

Standard (GP) vs High-Cube (HC) at a Glance

So, when do you choose one over the other? The decision comes down to your specific cargo and how you plan to load it.

- Standard 40 Ft Container (GP): This is the industry's go-to workhorse. It's perfectly suited for heavy, dense goods like machinery or raw materials, where you're more likely to hit the weight limit before you run out of vertical space.

- 40 Ft High-Cube Container (HC): That extra foot of vertical clearance makes the HC container ideal for lighter, bulkier cargo. Think furniture, apparel, or goods that can be double-stacked on pallets without exceeding weight limits.

Understanding this fundamental distinction is the first step in optimising your shipment. Making the right choice prevents both wasted space and the headache of overloading.

A Closer Look at the Standard 40 Ft Container

If you've ever seen a container ship, you've seen the standard 40 ft General Purpose (GP) container. It's the undisputed workhorse of global trade, a familiar sight on every vessel, train, and truck chassis around the world. Its standardised design is what makes modern shipping possible, so getting a handle on its exact specs is non-negotiable for anyone looking to move goods without making expensive mistakes.

The name "40-foot container" is a bit of a simplification. While the external length is set in stone by ISO standards to ensure it fits perfectly into the global logistics puzzle, the internal space—the part you actually get to load—is always a bit smaller. This is down to the container's own structure: its steel frame, corrugated walls, and sturdy floor all take up room.

External vs. Internal: Why the Difference Matters

One of the most common slip-ups for new shippers is planning cargo based on the external numbers. It’s an easy mistake to make, but that difference between the outer shell and the inner cavity can completely throw off your loading plan.

- External Dimensions: These are the container's overall measurements, the numbers that carriers and port operators care about. A standard 40 ft container is precisely 40 ft long, 8 ft wide, and 8 ft 6 inches high.

- Internal Dimensions: This is your actual, usable loading space. The thickness of the walls brings this down to roughly 39 ft 5 inches long, 7 ft 8 inches wide, and 7 ft 10 inches high.

What seems like a minor reduction of a few inches here and there adds up fast, affecting everything from how many pallets you can fit to your total usable volume. For this reason, you should always use the internal 40 ft container dimensions in feet for your packing calculations.

Don't forget the door opening. The entryway is always a little smaller than the internal height and width, which can create a final bottleneck for any large or awkwardly shaped items. For a standard 40 ft container, the door opening is usually around 7 ft 8 inches wide and 7 ft 5 inches high.

The Backbone of Global Shipping

The consistency of these dimensions is what turned international commerce into the well-oiled machine it is today. From the bustling ports of China, where a huge number of the world's containers are made, the standard 40-footer has been king since helping to power the country's export boom in the 1990s.

While the exterior measures 40 feet long, the usable space inside is closer to 39 feet 6 inches long, 7 feet 9 inches wide, and 7 feet 11 inches high. This gives you a total cubic capacity of about 2,401 cubic feet (68 m³). If you want to dig into these numbers further, you can find more insights on standard container sizes. This level of standardisation is what allows for predictable and efficient loading, no matter if you're shipping electronics, clothing, or heavy machinery.

When to Use a 40 Ft High-Cube Container

So, when does it make sense to upgrade to a 40 ft high-cube (HC) container? If your cargo is on the taller side, bulky, or you just need a bit more wiggle room, the HC is almost always the right call. It has the exact same footprint as a standard 40 ft box, but its real advantage lies in that extra foot of vertical space. This one change makes a world of difference for many importers.

A high-cube container has an external height of 9 feet 6 inches, a full foot taller than the standard 8-foot-6-inch unit. Inside, this gives you a usable height of around 8 feet 10 inches, which translates directly into more cubic capacity. For anyone shipping light but voluminous goods—think furniture or textiles—this extra space is pure gold.

This boost in volume makes the HC container the go-to option for certain types of cargo that would be a nightmare to ship otherwise.

Ideal Cargo for High-Cube Containers

The main benefit of that extra height is pretty straightforward: you can fit things that are too tall for a standard container, or you can stack more goods inside.

- Oversized Machinery and Equipment: Tall industrial parts, agricultural equipment, or manufacturing components that won't clear the door of a standard container often fit perfectly inside a high-cube.

- Lightweight, Bulky Goods: This is the HC's sweet spot. Things like furniture, clothing, and textiles have a low density. You can stack them high to the ceiling, filling every available inch of volume without ever getting close to the container's weight limit.

- Double-Stacked Pallets: If your palletised goods are stable and not too heavy, the extra headroom allows for double-stacking. This simple move can effectively double your usable floor space, which is a massive win for efficiency.

The Rise of the High-Cube

The real-world benefits of the high-cube container are undeniable. In fact, high-cubes now make up over half of the entire global shipping container fleet. This isn't just a trend; it's a fundamental shift in logistics, as shippers increasingly prioritise the flexibility and extra capacity these containers offer.

Picking the right container isn't just about dimensions—it's a strategic move that directly affects your shipping costs and overall efficiency. The high-cube gives shippers a powerful tool to maximise their space and get more value from every shipment.

For a closer look at the exact specifications, you can find out more about the 40 HQ container size and see how it fits into your shipping plans. Getting these details right is key to choosing the most cost-effective option, particularly when you're importing from major manufacturing hubs like those in China.

Mastering Container Weight and Volume Capacity

Knowing the physical 40 ft container dimensions in feet is one thing, but truly mastering its capacity means getting the balance between volume and weight just right. Every single container is governed by three critical weight specifications. These aren't just suggestions; they dictate exactly how much cargo you can legally and safely load for transport.

For anyone planning freight, these figures are non-negotiable. You have to be familiar with them to avoid overloading, which is a fast track to fines, delays, and serious safety issues. It’s also a crucial part of complying with road trucking rules and the mandatory pre-trip inspection requirements for commercial vehicles. Get this wrong, and you could bring your entire supply chain to a halt.

Key Weight Definitions

Let's break down the three numbers that define a container's real-world load capacity. Each plays a specific role in how you should calculate your shipment.

- Tare Weight: Think of this as the empty weight of the container itself—just the steel box, its flooring, and fixtures. For a standard 40 ft container, this is usually around 8,200 lbs (3,720 kg).

- Max Payload: This is the big one. It's the maximum weight of the actual cargo you are allowed to load inside. For a standard 40 ft unit, you're looking at a limit of about 58,920 lbs (26,725 kg).

- Max Gross Weight: This is the absolute total weight allowed for the container and its contents combined. Simply put, it's the Tare Weight + Max Payload. This total sum cannot go over the limit, which is typically set at 67,200 lbs (30,480 kg).

Translating Space Into Volume

Weight is only half the story. The internal space, or cubic capacity, is just as important for filling out shipping documents and calculating your freight costs. This number tells you the total usable volume inside the container, usually expressed in cubic feet (cu ft) or cubic meters (CBM).

A standard 40 ft container gives you roughly 2,390 cubic feet of packing space. If you opt for a high-cube version, that number jumps to about 2,694 cubic feet. That extra vertical space is precisely why high-cubes are the go-to choice for cargo that is bulky but not necessarily heavy.

For a deeper dive into these calculations, our guide on how many CBMs are in a 40 ft container breaks it all down.

Here’s a quick-reference table to keep these key figures straight.

Weight and Volume Capacity of 40 Ft Containers

| Metric | Standard 40 Ft Container (GP) | 40 Ft High-Cube Container (HC) |

|---|---|---|

| Tare Weight | ~8,200 lbs / 3,720 kg | ~8,598 lbs / 3,900 kg |

| Max Payload | ~58,920 lbs / 26,725 kg | ~58,522 lbs / 26,545 kg |

| Max Gross Weight | 67,200 lbs / 30,480 kg | 67,120 lbs / 30,445 kg |

| Cubic Capacity | ~2,390 cu ft / 67.7 CBM | ~2,694 cu ft / 76.3 CBM |

As you can see, while the High-Cube offers more volume, its slightly higher tare weight means a marginally lower max payload. It's a trade-off you need to consider based on your specific cargo.

Ultimately, successful shipping comes down to a careful balancing act. You must ensure your cargo's total volume fits snugly inside while its total weight stays safely under the maximum payload limit. If you exceed either one, you're risking rejected shipments and a pile of unexpected costs.

Getting the Most Out of Your Space: Smart Pallet Loading

Knowing the raw 40 ft container dimensions in feet is one thing, but actually using that space effectively is another. It all comes down to how you load your pallets. Just throwing loose cartons onto the container floor is a recipe for inefficiency and damage. A smart pallet plan, on the other hand, protects your products, makes loading and unloading a breeze, and ultimately drives down your cost per unit because you can ship more in one go.

The trick is to think about how your pallet footprint fits within the container's internal floor space. When shipping from China, you'll generally come across two dominant pallet sizes, and each one arranges differently inside the container. Getting this right is the first real step toward a smoother, more cost-effective shipment.

Common Pallet Configurations

How many pallets you can squeeze in depends entirely on their size. The two most common types you’ll encounter have very different capacities.

- Standard Pallets (1000mm x 1200mm): For this size, you can usually line up 20 or 21 pallets in a single layer on the container floor. The most common arrangement is placing them two-wide across the container's width.

- Euro Pallets (800mm x 1200mm): These are a bit narrower, which means you can fit more of them—typically 23 to 24 units. This often requires a slightly more creative layout to really maximise the floor area, but the extra capacity is worth it.

It’s this kind of dimensional planning that makes global intermodal freight work so well. For context, major rail operators confirm that a standard 40 ft container is built to hold 20 of the similarly sized 48x40 inch pallets, making the most of its 2,395 cubic feet of usable space.

Next-Level Loading Techniques

Once you've got the basics down, a few advanced techniques can help you pack your container to the gills, especially if you're using a high-cube model.

Pro Tip: Always leave a few inches of buffer space between your pallets and the container walls. It seems counterintuitive, but this small gap prevents shifting cargo from getting damaged and gives a forklift operator the room they need for a smooth unload.

One popular method is called pinwheeling. This involves alternating the direction of rectangular pallets—some go in lengthwise, others widthwise. It’s a great way to fill in odd gaps and make the entire load tighter, which means less movement and potential damage during the journey.

For anyone in manufacturing, planning for containerisation starts long before the products hit the loading dock. A solid grasp of these techniques is invaluable, as it connects the design phase to the final shipment. It’s a key part of what’s covered in a manufacturer's guide from concept to container.

Another powerful strategy is double-stacking. If your products are sturdy but not too heavy, you can often place a second loaded pallet right on top of the first. This is where a high-cube container really shines; that extra foot of vertical space can essentially double your capacity. Just be absolutely sure you’re not going over the container's maximum payload limit.

FCL vs. LCL: Which Shipping Strategy Makes Sense for You?

Knowing the exact 40 ft container dimensions in feet is more than just a technical detail—it’s the key to figuring out the smartest, most cost-effective way to ship your goods. Your decision will almost always boil down to two options: Full Container Load (FCL) or Less than Container Load (LCL).

The right choice hinges entirely on the volume of your cargo. Picking correctly can save you a significant amount on shipping costs, cut down transit times, and generally make your logistics run a whole lot smoother.

Understanding Full Container Load (FCL)

When you opt for Full Container Load (FCL), you're essentially renting the entire container for your exclusive use. You pay a single flat fee for the whole space, regardless of whether you pack it to the ceiling or only use half of it.

This becomes the go-to, economical choice once your shipment volume hits a certain point—usually somewhere around 15 to 20 cubic metres (CBM). FCL has some great perks, too. Your goods are handled less, which lowers the risk of damage, and shipping is often faster since your container isn't making extra stops to pick up other cargo. It goes straight from your supplier to its final destination.

When to Choose Less than Container Load (LCL)

On the flip side, Less than Container Load (LCL) is the perfect solution for smaller shipments that won't come close to filling a 40 ft container. With LCL, your cargo shares space inside a container with goods from other importers.

You only pay for the specific volume your shipment takes up, measured in CBM. This makes it a really flexible and budget-friendly option for businesses shipping smaller quantities. The trade-off? LCL shipments can take longer because the container has to stop for consolidation (loading other goods) and deconsolidation (unloading them) along the way.

Key Takeaway: The decision is pretty straightforward. Once your cargo volume gets large enough that the flat rate for an FCL container is cheaper per unit than paying by volume for LCL, it’s time to make the switch to FCL.

For a deeper dive into this, check out our complete guide comparing FCL and LCL shipping. It provides more detailed insights to help you lock in the best strategy for your imports from China.

Common Questions About 40 Ft Containers

Even with all the specs laid out, real-world questions always pop up when you're in the thick of planning a shipment. Let's tackle some of the most common queries we hear from shippers about 40 ft container dimensions in feet. Getting these details right can save you a lot of headaches down the line.

What Is the Main Difference Between a 40 Ft Standard and High-Cube Container?

The only difference is height—but that one foot makes a world of difference. A 40 ft high-cube container gives you an external height of 9 feet 6 inches, while the standard is 8 feet 6 inches.

That extra foot of vertical space makes the high-cube the go-to choice for taller goods or light, bulky cargo that you can stack high, like furniture or textiles. You get to max out the volume without worrying about hitting the weight limit.

If you're shipping heavy, dense materials, a standard container will do the job just fine. But if you need every last cubic inch of space, the high-cube is your best bet.

Can a 40 Ft Container Hold Double the Cargo of a 20 Ft Container?

This is a common misconception, and the answer is a firm no. While a 40 ft container offers a bit more than double the cubic capacity of a 20-footer, its maximum payload (the weight of the cargo it can carry) is definitely not double.

This makes the 40 ft container perfect for lighter goods where you're filling the space before you hit the weight limit. For extremely dense cargo like scrap metal or stone, you’d likely hit the maximum weight in a 20 ft container long before you run out of physical space.

Important Note: Always think about both volume and weight. A 40 ft container is for volume-heavy shipments, while a 20 ft is often better suited for weight-heavy cargo.

Are 40 Ft Reefer Container Dimensions the Same?

They aren't. The internal, usable space in a 40 ft refrigerated container (a "reefer") is noticeably smaller. The refrigeration unit at the front and the thick insulation needed to maintain temperature eat into the internal length, width, and height.

If you're shipping anything that needs to be kept cool, you absolutely must get the specific internal dimensions from your freight forwarder. The last thing you want is to find out your carefully packed cargo won't fit because you assumed the reefer had the same space as a standard dry container.