When you're trying to figure out the volume of a 40-foot container, you'll quickly discover there isn't just one simple answer. It all depends on the specific type of container you're using. A standard 40-foot box will give you around 67 cubic meters (CBM) of space, but a High Cube version, with its extra foot of height, bumps that up to a more generous 76 CBM.

Getting this right is your first step toward getting an accurate freight quote and planning your shipment properly.

Your Quick Answer to 40ft Container Volume

Knowing the exact cubic meter capacity of your container is crucial for logistics planning and, ultimately, for controlling your costs. The reason the answer to "how many cubic metres in a 40ft container" changes is simple: different containers are built for different jobs, and that design directly affects how much you can actually fit inside.

To give you a reliable starting point, we've pulled together the real-world, usable CBM for the three most common 40ft containers you'll encounter. These numbers account for the space taken up by the container's internal structure and the clearance needed for the doors—think of this as your practical loading guide.

40ft Container CBM Capacity at a Glance

This table breaks down the usable internal volume for the main types of 40ft containers, giving you a quick comparison.

| Container Type | Typical Usable CBM | Maximum Usable CBM |

|---|---|---|

| Standard (GP) | 63–65 CBM | ~67 CBM |

| High Cube (HC) | 72–74 CBM | ~76 CBM |

| Reefer (Refrigerated) | 55–58 CBM | ~60 CBM |

Consider these numbers your foundation. From here, we'll get into what these volumes actually mean for your cargo, how to calculate your shipment's CBM, and how to make the most of every last cubic metre. It’s all about helping you ship smarter and more cost-effectively.

Understanding CBM: The Universal Language of Global Freight

Before we get into the nitty-gritty of container sizes, let's talk about the single most important measurement in shipping: the Cubic Metre (CBM). Think of it as the universal language for space in the world of logistics. It’s a bit like packing a moving lorry—you’re less concerned with the exact weight of each box and more focused on how much physical room everything takes up.

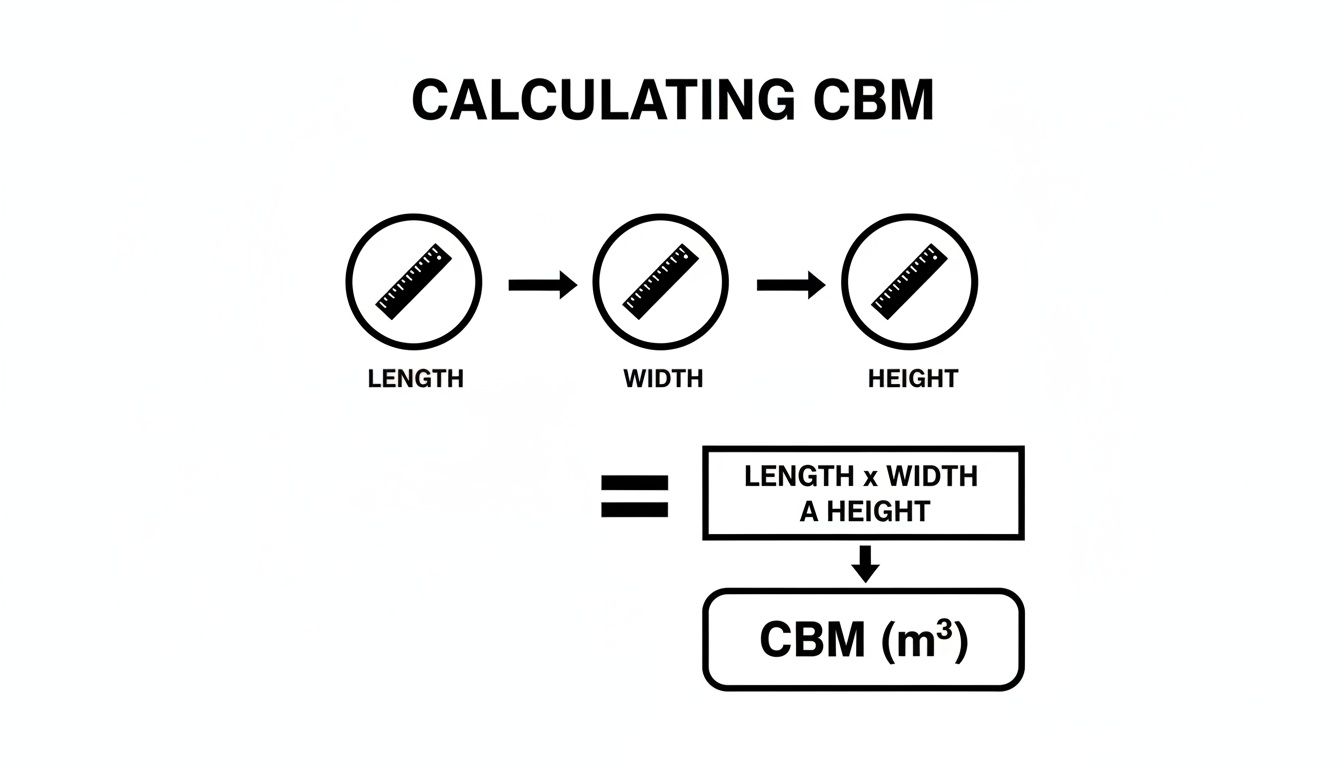

CBM is exactly that: the volume your cargo occupies. The calculation is straightforward: Length × Width × Height, with all measurements in metres. This one number tells a freight carrier precisely how much space your shipment will need, whether it's in a massive container ship or the cargo hold of an aircraft.

Why CBM Is More Than Just a Number

Getting a handle on CBM is vital because it often directly determines your shipping cost. This is especially true for goods that are light but bulky—think of things like furniture, styrofoam, or bags of cotton. For this kind of cargo, the space it consumes is far more valuable to the carrier than its actual weight.

This concept is absolutely fundamental to getting an accurate quote and steering clear of surprise fees. When you're navigating global freight, speaking the language of CBM is non-negotiable, particularly when you're choosing a freight forwarder for Amazon FBA and need a solid supply chain. Mastering this simple calculation gives you the power to double-check costs and communicate clearly with your logistics partners.

Key Takeaway: Freight forwarders and carriers price shipments using CBM because space on any vessel is a limited, valuable commodity. For lighter goods, it's the CBM, not the kilogram, that really drives your final shipping rate.

Ultimately, understanding CBM helps you answer the big question: how many cubic metres in a 40ft container will my goods actually fill? By calculating your cargo’s total CBM, you can quickly figure out if you have enough freight to justify a Full Container Load (FCL) or if a Less than Container Load (LCL) shipment makes more sense for your budget. It’s the first real step toward smart load planning and keeping your costs in check.

A Closer Look at 40ft Container Capacities

When you ask, "how many cubic metres are in a 40ft container?", the answer isn't a single number. The reality is, not all 40ft containers are created equal. The specific type you choose has a direct impact on how much you can actually fit inside, and picking the right one is the first step to shipping efficiently. Let's break down the three workhorses of the logistics world.

The core concept behind all this is the cubic metre, or CBM. It's simply the volume of your cargo, and you can figure it out with a straightforward formula: Length × Width × Height (in metres). This is the bedrock of all freight volume calculations.

The image below gives you a clear visual of how these three measurements come together to determine the total CBM.

As you can see, all it takes are these three dimensions to calculate the volume of any given space—including the inside of a shipping container.

The 40ft Standard General Purpose Container

The 40ft Standard or General Purpose (GP) container is the industry's default choice. It's the most common and versatile box on the water, handling everything from electronics and clothing to countless other dry goods. Think of it as the reliable family car of shipping.

Because it's so widely used, it serves as a great benchmark. You'll find that most standard 40ft GP containers offer a usable internal volume of around 67 to 70 cubic metres. This capacity makes it a fantastic, cost-effective solution for the vast majority of shipments.

The 40ft High Cube Container

Next up is the 40ft High Cube (HC) container. At first glance, it looks just like its standard sibling, but it has a secret weapon: an extra foot of height. This might not sound like much, but for shippers dealing with tall or bulky cargo, that extra space is a game-changer.

Key Insight: That single extra foot of height bumps the total capacity from around 67 CBM to about 76 CBM. That’s a nearly 15% increase in usable space for what is usually only a small increase in cost.

This makes the High Cube the perfect choice for:

- Light but bulky goods, like furniture, apparel, or raw materials that take up a lot of room.

- Oversized equipment that is just a bit too tall for a standard container.

- Maximising pallet space by allowing you to stack goods higher, which can dramatically lower your cost per item.

If your cargo is tall, or you’re trying to squeeze in just a bit more product to avoid paying for a whole new container, the High Cube is often the smartest move you can make. For a deeper dive into how these containers stack up, check out our guide on the full dimensions of a 40 ft container.

The 40ft Reefer Container

Finally, we have the 40ft Reefer (refrigerated) container. This is a specialised piece of equipment, essentially a giant, mobile refrigerator built to transport temperature-sensitive cargo like pharmaceuticals, fresh produce, and frozen foods.

That climate-control technology, however, comes at the cost of internal space. The refrigeration unit and the thick, insulated walls needed to maintain a constant temperature eat into the available volume. A 40ft reefer typically offers only 55 to 60 CBM, sacrificing some capacity to ensure that valuable, perishable goods arrive in perfect condition.

Figuring Out Your Shipment's Total CBM

Now that we've covered container capacities, let's get practical and apply it to your own cargo. Calculating your shipment's total CBM is a vital skill. It puts you in the driver's seat, letting you double-check quotes, plan your container layout, and speak the same language as your freight forwarder.

And don't worry, it's simpler than it sounds.

The whole process boils down to one simple formula. Once you've got the measurements for your packages, you can figure out exactly how much space you're going to need.

The CBM Formula:

Length (m) × Width (m) × Height (m) = CBM per Package

This little equation is the bedrock of all freight volume calculations. If you want to dive even deeper, we have a complete walkthrough in our guide on how to calculate CBM for shipping.

A Quick CBM Calculation Example

Let's put the formula to work with a real-world example. Say you need to ship 200 identical cartons.

First thing's first: make sure all your measurements are in metres. This is a classic rookie mistake—using centimetres or inches will throw your entire calculation off. Let's assume each of your boxes measures:

- Length: 60 cm (0.6 m)

- Width: 40 cm (0.4 m)

- Height: 30 cm (0.3 m)

Now, just plug those numbers into the formula to get the CBM for a single box:

0.6 m × 0.4 m × 0.3 m = 0.072 CBM

Easy enough. The final step is to multiply that single-box CBM by the total number of boxes you're shipping:

0.072 CBM × 200 boxes = 14.4 CBM

With a total volume of 14.4 CBM, you can see right away that this shipment is a prime candidate for a Less than Container Load (LCL) service. It's nowhere near filling a whole 40ft container. Speaking of which, from the bustling ports of Hong Kong—a lynchpin in China's shipping world—the standard 40ft container has been the backbone of global trade, typically holding around 60-67 cubic metres. You can find some great background on container sizes and their history on crownrelo.com.

How to Squeeze Every Last Cubic Metre Out of Your Container

Knowing the CBM of a 40ft container is one thing. Actually using all that space is where the real skill—and the real savings—come in. A poorly packed container means you're literally paying to ship empty air, so getting your loading strategy right from the start is absolutely essential.

Your game plan should be locked in before a single box is even touched. Smart planning is all about cutting down on wasted volume, or ‘dead space’, to ensure you get maximum value for your money. This is especially true when you're dealing with larger containers. For example, in Dongguan, one of China's main hubs for container manufacturing, the 40ft High Cube (HC) is king. It gives you 76 cubic metres to play with—a full 10 CBM more than a standard container. That extra height is a godsend for bulky goods like furniture.

Smart Stacking: Pallets and Loose Cargo

Pallets are the foundation of an efficient load, but your choice of pallet can make or break your space efficiency.

- Standard Pallets (1.2m x 1.0m): These are widely used, but their dimensions can sometimes create awkward, unusable gaps along the container walls.

- Euro Pallets (1.2m x 0.8m): The slightly narrower profile often allows for a much tighter, more efficient configuration, leaving very little dead space.

If you're loading loose cargo without pallets, think of it like a real-life game of Tetris. The golden rule is to place your heaviest, most robust items at the bottom to create a stable base. Then, you can fill in the gaps and crevices with smaller, lighter, or more irregularly shaped items. The end goal is a solid, tightly packed block of cargo that won't shift in transit.

Expert Tip: A well-loaded container is about more than just volume. You have to get the weight distribution right for safety and compliance. Keep heavier items centred along the container's floor and spread the load evenly from front to back. This prevents dangerous tilting while on the road or at sea.

FCL vs. LCL: Making the Final Call

At the end of the day, your total CBM is the deciding factor in how you ship. If your cargo is going to fill a good chunk of a container—let's say over 15 CBM—then booking a Full Container Load (FCL) makes the most sense. You get the whole container to yourself.

But for smaller shipments, Less than Container Load (LCL) is the way to go. It's far more economical because you're only paying for the specific volume your goods occupy, sharing the rest of the space with other shippers. Understanding which one is right for you is fundamental to controlling your logistics costs. To get a clearer picture, take a look at our guide on the differences between LCL and FCL shipping.

Common Questions About 40ft Container Capacity

To wrap things up, let's go through a few questions that pop up all the time when people are planning their shipments. Getting these details right can save you a lot of headaches and money down the line.

Can I Actually Use All the CBM in a Container?

That’s a great question, and the honest answer is no, you can't. The official CBM rating is the container's total internal volume, but practically speaking, you’ll never fill 100% of that space. Think of it like packing a moving truck—there are always going to be little gaps and awkward spaces you just can't fill.

You'll inevitably lose some usable space to a few things:

- Odd-Shaped Cargo: Not everything is a perfect, stackable cube. Irregularly shaped items create gaps.

- Loading Inefficiency: Small spaces between pallets, boxes, and the container walls are unavoidable.

- Dunnage: You need materials like airbags, straps, or wooden braces to stop your cargo from shifting around, and all that takes up room.

A good rule of thumb is to assume you can only use about 85-90% of the container's total CBM. For a standard 40ft container rated at 67 CBM, that means you should realistically plan for a loading volume of around 57–60 CBM.

How Do CBM and Weight Factor into My Final Price?

This is where it gets interesting. While CBM tells you the volume, your final freight bill is based on what's called chargeable weight. The carrier will look at two things: the actual, physical weight of your cargo and its volumetric weight (a figure calculated from its CBM). They will then charge you based on whichever number is higher.

Let's take two extremes. Imagine shipping a container packed with pillows versus one filled with lead weights. The pillows take up a huge amount of space (high CBM) but are incredibly light. The lead, on the other hand, is extremely heavy but takes up very little room (low CBM).

The Weight or Measurement Rule: Carriers charge for the greater of the two: actual weight or volumetric weight. This system ensures they're fairly paid for carrying both heavy, dense cargo and light, bulky goods that take up a lot of valuable space.

This is exactly why just knowing how many cubic metres are in a 40ft container is only half the story. You have to consider your cargo’s weight to get a clear idea of your actual shipping costs.

Is it Worth Paying Extra for a High Cube Container?

Choosing whether to upgrade to a High Cube (HC) container is usually a pretty straightforward bit of maths. Yes, an HC container costs a bit more than a standard one, but it gives you an extra foot of height, which translates to about 9-10 extra CBM of space.

Here’s a simple way to think it through:

- Calculate Your Total CBM: Work out the total volume of all your cargo.

- See if You're Just Over: Does your shipment barely miss the cut-off for a standard 40ft container's usable space (around 60 CBM)?

- Do the Cost Comparison: Let's say your shipment comes out to 65 CBM. Paying a small premium for a High Cube with 76 CBM of capacity is a no-brainer. It's infinitely cheaper than booking a whole second container or splitting your shipment into two.

If you have tall cargo or if that extra vertical space is exactly what you need to squeeze everything in, the High Cube is almost always the right call.