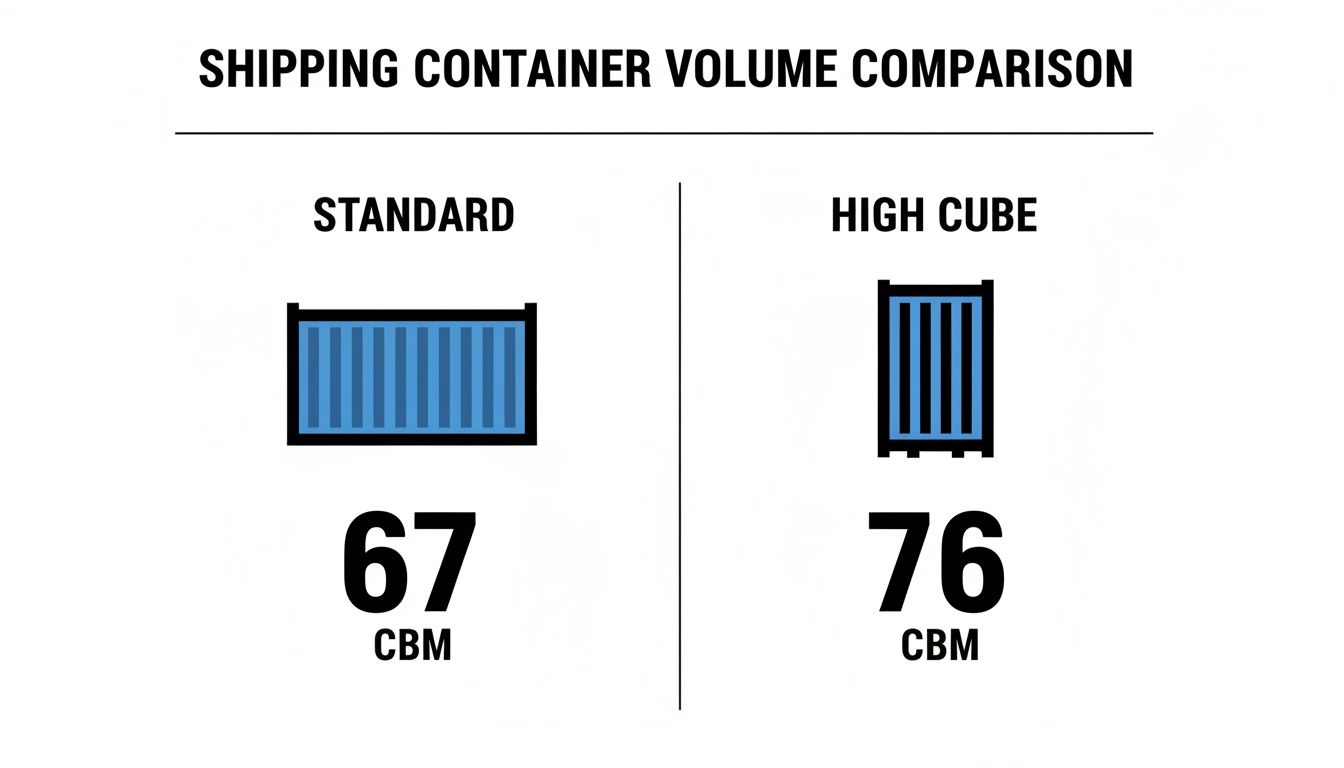

When you're trying to figure out how much you can fit into a 40-foot shipping container, the magic number you need is its CBM, or cubic metre capacity. On paper, a standard 40-foot container offers a maximum volume of 67.7 CBM, while its taller counterpart, the high cube, provides a more generous 76.4 CBM.

But here's the catch every seasoned importer knows: you can never actually use 100% of that space.

Your Quick Answer to 40-Foot Container CBM

The answer to "how many CBM in a 40-foot container" isn't just one number. It all depends on the type of container you book: a standard General Purpose (GP) container or a High Cube (HQ). The only real difference between them is their height, but that extra bit of vertical space in a high cube can make all the difference for your total cargo volume.

While we often talk about containers in feet, it’s the internal metric measurements that count for your cargo. These are what determine how your boxes, pallets, or equipment will actually fit inside.

The key thing to remember is that the maximum theoretical volume listed on a spec sheet and the practical, usable volume are two very different things.

The Reality: Usable vs. Maximum CBM

Think of it like packing a moving box. No matter how neatly you arrange your things, there will always be small, empty gaps you just can't fill. The same logic applies to loading a massive steel container.

Irregularly shaped items, the space taken up by pallets, and the essential gaps left for airflow or safe loading all eat into the total CBM. A smart rule of thumb is to assume you'll only be able to use about 85-90% of the container's advertised maximum volume.

A container's spec sheet tells you its maximum CBM, but smart logistics planning focuses on the usable CBM. Overlooking this distinction is a common and costly mistake that can lead to rejected cargo or last-minute shipping changes.

40-Foot Container CBM at a Glance

To make it simple, here’s a quick reference table breaking down the vital stats for both standard and high cube 40-foot containers.

| Container Type | Maximum Volume (CBM) | Typical Usable Volume (CBM) | Internal Height |

|---|---|---|---|

| 40ft Standard (GP) | 67.7 CBM | 56–61 CBM | 2.39 m |

| 40ft High Cube (HQ) | 76.4 CBM | 65–68 CBM | 2.70 m |

Keeping these figures in mind from the get-go helps you make the right call. It’s the first step to avoiding the headache of booking a container that’s just a little too small for your cargo, a mistake that can cost you serious time and money.

For a deeper dive into all the measurements, you might find our guide on 40-foot container dimensions in feet really helpful.

Standard vs High Cube: A Crucial CBM Difference

When you're looking to ship in a 40-foot container, one of the first decisions you'll make is whether to go with a standard (GP) or a High Cube (HQ) model. They have the exact same floor space, but that extra bit of height in a High Cube makes a massive difference in CBM—and ultimately, how much you can fit inside.

Imagine you have two rooms with identical floor plans. One has a normal ceiling height, the other a vaulted one. The floor space is the same, but that taller room just feels bigger and gives you a lot more vertical storage. That’s precisely the advantage a High Cube container gives your cargo.

A standard 40-foot container has an internal height of about 2.39 metres, which gives you a theoretical maximum volume of around 67 CBM. It's a solid, versatile choice for many types of goods.

The High Cube Advantage

The High Cube, on the other hand, gives you about an extra foot (or 30 cm) of headroom, pushing its internal height up to 2.70 metres. It might not sound like much, but this boosts its total capacity to roughly 76 CBM. That’s almost a 15% increase in usable space, which can be a real game-changer.

This extra vertical space is perfect for cargo that is:

- Tall but Lightweight: Think unassembled furniture, large plastic products, or bulky retail displays. You can stack them higher without worrying about the weight limit.

- Irregularly Shaped: Tall machinery or awkward equipment that just won’t squeeze into a standard container often fits perfectly in a High Cube.

- Volume-Heavy: If you’re shipping light but bulky goods like clothing, textiles, or insulation, the extra CBM means you can pack more into one container, driving down your cost per item.

For anyone shipping goods, the choice isn't just about space; it's about cost efficiency. That extra 9 CBM in a High Cube often costs just a little more than a standard container, making it a much smarter economic choice when you need to maximise volume.

Making the Right Choice for Your Cargo

So, which one is right for you? It all boils down to what you’re shipping.

If your cargo is dense and heavy—like stone slabs or metal parts—you're going to hit the container's weight limit long before you fill up the space. A standard container will do the job just fine.

But if you're dealing with lighter, bulkier goods, the High Cube is almost always the better financial move. This is a common understanding among global logistics providers. For example, Mainfreight lists the 40ft High Cube container with a 76 CBM capacity and internal dimensions of 12.05m L x 2.35m W x 2.69m H, highlighting its suitability for shipments from major industrial centres. You can see more details on the Mainfreight container info page. Truly understanding the dimensions of a 40 HC container is key to planning your load properly.

By taking a moment to consider your cargo’s height and density, you can pick the container that delivers the best value—ensuring you don’t pay for space you don't need or, even worse, find yourself short on room.

Figuring Out the CBM for Your Shipment

Now that we've covered the total volume of a 40-foot container, let's bring the focus back to what you're actually shipping: your goods. Getting an accurate CBM calculation for your cargo is probably one of the most critical steps in planning your shipment. It's the key to getting a reliable freight quote and making sure you book the right type of container.

The good news? You don't need any fancy software to do this. A measuring tape and a basic calculator are all it takes.

The CBM Formula in Action

To work out the cubic metre volume of a single carton, you just need to multiply its length, width, and height. The important part is to make sure your measurements are in metres.

The formula looks like this:

CBM per Carton = Length (m) x Width (m) x Height (m)

If you're shipping a bunch of cartons that are all the same size, you can find your total volume by multiplying that result by the number of cartons you have. It's a straightforward, two-step process that gives you a solid number to work with.

To make this crystal clear, let's walk through a few common scenarios.

CBM Calculation Examples

Here’s a table showing how the CBM formula is applied to different types of shipments, from a single small box to a larger order with mixed carton sizes.

| Shipment Item | Dimensions (L x W x H in meters) | CBM per Unit | Total CBM |

|---|---|---|---|

| 1 small carton | 0.6m x 0.4m x 0.5m | 0.12 CBM | 0.12 CBM |

| 150 identical cartons | 0.6m x 0.4m x 0.5m | 0.12 CBM | 18 CBM |

| 50 large cartons | 1.2m x 0.8m x 0.6m | 0.576 CBM | 28.8 CBM |

| Mixed Shipment (20 small + 30 large) | Small: 0.6x0.4x0.5, Large: 1.2x0.8x0.6 | Small: 0.12, Large: 0.576 | (20 x 0.12) + (30 x 0.576) = 19.68 CBM |

As you can see, the process is simple multiplication. For mixed shipments, you just calculate the CBM for each group of same-sized cartons and then add those figures together for a grand total.

With your total CBM in hand, you can start making some smart decisions. For a more detailed guide and a handy calculator tool, check out our post on how to calculate CBM.

The infographic below puts the container capacities into perspective, giving you a clear benchmark to compare your shipment's total CBM against.

That side-by-side view really drives home the 9 CBM of extra space you get with a high cube container—a difference that can be a game-changer.

Once you’ve mastered this simple calculation, you can approach freight forwarders with confidence, knowing precisely how much space you need. This is how you avoid the classic mistakes of paying for a half-empty container or, even worse, finding out your cargo won't fit when the truck is at your door. It’s the first real step towards taking control of your shipping costs.

Why You Can't Use Every Last Inch of a Container

Thinking you can squeeze 67 CBM of cargo into a container rated for 67 CBM is one of the most common—and expensive—mistakes an importer can make. It's a trap I've seen catch even experienced shippers off guard.

That maximum volume you see on a spec sheet is a purely theoretical number. It’s calculated as if you were filling the container with water, a liquid that perfectly fills every nook and cranny. But we don't ship water; we ship boxes, pallets, and oddly-shaped goods. In the real world, you'll never hit that maximum figure.

The gap between the advertised volume and what you can actually load is where costs add up and delays begin. This difference isn't random; it's caused by a handful of "space eaters" that are just part of the reality of loading a container. Getting a handle on these is the key to planning a smooth shipment.

The Hidden Space-Eaters

Several factors consistently eat into your usable space. Each one shaves a little off that maximum CBM, leaving you with a much more realistic number to work with for your packing list.

Here’s what you’re up against:

- Awkward Shapes: Very few products are perfect cubes. Machinery, furniture, or even cartons of different sizes inevitably create gaps and pockets of dead air that you simply can't fill.

- Pallets & Dunnage: If your goods are on pallets, the pallets themselves take up floor space and volume. Then there’s dunnage—all the airbags, wooden braces, and foam used to stop your cargo from shifting—which also consumes valuable space.

- Manoeuvring Room & Airflow: You can't just jam everything in tight. Packers need a little wiggle room to get cargo into place safely. Plus, some goods need air to circulate to prevent mould or overheating, which means leaving intentional gaps.

- The Container Walls: Look closely inside a container. The corrugated walls and lashing points aren't perfectly flat. These small ridges and fixtures prevent boxes from sitting flush, creating hundreds of small, wasted gaps that add up.

As a solid rule of thumb, you should plan on your usable CBM being around 80-90% of the container's stated maximum. This isn't pessimism; it's professional load planning.

So, for a standard 40-foot container with that theoretical max of 67 CBM, you should really be planning to load somewhere between 54 and 58 CBM. Pushing your luck beyond that is a gamble that rarely pays off.

Understanding this distinction is what separates a rookie from a seasoned pro. By basing your shipment on the usable CBM, you ensure everything actually fits. It’s a simple step that helps you book the right container from the start, avoiding that horrible, costly surprise of discovering you need a bigger container when your cargo is already waiting at the port.

Balancing CBM with Container Weight Limits

It’s a classic rookie mistake to focus only on how many CBM are in a 40-foot container. While volume tells you how much space you have, the payload is the other side of the coin. Payload is the maximum legal weight a container can carry, and ignoring it is one of the fastest ways to derail your shipment.

Think of it like packing a rucksack for a hike. You could stuff it to the brim with feathers and barely feel it. But if you try to fill that same rucksack with rocks, you'll hit your own carrying limit long before the bag looks full. A shipping container works the same way.

Heavy, dense cargo—things like steel coils, ceramic tiles, or industrial machinery—can easily hit the container's weight limit while leaving plenty of empty space inside.

Payload: The Invisible Barrier

So, what's the magic number? Most 40-foot containers have a maximum payload somewhere between 26 and 28 metric tons (that's 26,000–28,000 kg). This isn't a friendly suggestion; it’s a hard and fast rule enforced by shipping lines, port authorities, and road transport regulators.

Trying to sneak past this limit is a bad idea. The consequences are steep and can completely halt your supply chain.

- Rejected at the Gate: Your container can be turned away at the port, leading to expensive unloading and repacking fees.

- Hefty Fines: Overweight containers caught on the road lead to serious fines for breaking safety laws.

- Serious Safety Risks: An overloaded container puts incredible strain on cranes, ships, and truck chassis. It's a genuine safety hazard for everyone involved.

You can always find the official weight limits on the container's CSC plate (which stands for Convention for Safe Containers). This is a small metal plate, usually on the doors, that lists the maximum gross weight and the tare weight (the container's empty weight). Simply subtract the tare from the gross, and you have your maximum payload.

Here’s the golden rule: You will always run out of either space (CBM) or weight capacity (payload) first. Your job is to figure out which one it will be for your specific cargo.

A shipment of bulky furniture, for instance, will almost certainly fill the container's CBM long before it gets too heavy. On the other hand, a load of cast iron parts would hit the payload limit using just a small corner of the container. Mastering both volume and weight ensures your goods are packed efficiently, shipped legally, and arrive safely.

Tips for Squeezing Every Last CBM Out of Your Container

Knowing the theoretical CBM of a 40-foot container is one thing. Actually using that space effectively is a whole different ball game. Smart packing isn't just about cramming more stuff in; it's about making sure your goods are safe, the load is stable, and you're getting maximum value for every dollar you spend on freight.

Just tossing boxes into a container is a sure-fire way to end up with damaged products and wasted money. Seasoned shippers have developed tried-and-true methods for creating a tight, secure load that can handle the bumps and rolls of a long ocean voyage.

Strategic Packing: Think Like a Tetris Master

To really get the most out of your container's CBM, you need to think like a logistics expert. Every single choice you make during loading affects how much you can safely ship. A well-planned load is a masterclass in efficiency and security.

Here are a few essential techniques the pros use:

- Standardise Your Boxes: If you can, stick to boxes of the same size. This lets you stack them in stable, interlocking blocks, just like building with bricks. It's the single best way to reduce wasted gaps and make the entire load more secure.

- Heavy at the Bottom, Light on Top: This is a golden rule. Your heaviest items should always go on the floor, spread out evenly. Lighter goods get stacked on top. This prevents fragile items from being crushed and keeps the container's centre of gravity low and stable.

- Use Dunnage Smartly: Dunnage is the industry term for filler materials like inflatable airbags, foam, or even simple wood braces. Their job is to plug any gaps and stop your cargo from shifting around at sea. Good dunnage is your best insurance policy against transit damage.

The Great Debate: Pallets vs. Floor-Loading

One of the biggest calls you'll make is whether to load your goods on pallets or stack them directly on the container floor. There’s no single right answer; it’s a trade-off between space, speed, and safety.

| Loading Method | Pros | Cons |

|---|---|---|

| Palletising | Much faster to load and unload; offers better protection for goods. | Pallets themselves eat up valuable CBM and add to the total weight. |

| Floor-Loading | Maximises every inch of CBM by getting rid of pallet space. | Slower, more labour-intensive, and carries a higher risk of damage if not done perfectly. |

As a rule of thumb, floor-loading can free up an extra 10-15% of usable space. But be warned, it demands more manual work and meticulous planning to keep the load from shifting.

The decision between FCL and LCL shipping often boils down to a simple CBM threshold. If your cargo volume hits 15 CBM or more, it’s almost always cheaper per cubic metre to book your own Full Container Load (FCL) rather than pay the premium for sharing space in a Less than Container Load (LCL) shipment.

In the end, packing a container is a balancing act between volume, weight, and safety. By using uniform packaging, loading smart, and choosing the right method, you can make sure your goods arrive in perfect condition while getting the absolute most from your freight costs.

Common Questions We Hear About 40-Foot Containers

Even after you've run the numbers on CBM and weight, a few practical questions always pop up. Let's tackle some of the most common ones we see from shippers who are getting ready to load a 40-footer.

How Many Pallets Can I Squeeze into a 40-Foot Container?

This is a big one. For a standard 40-foot container, you can generally lay down 20 standard American pallets (100cm x 120cm) in a single layer. If you're using Euro pallets (80cm x 120cm), you can often fit up to 24. It all comes down to how you arrange them on the floor.

Now, a high cube container gives you more headroom, but the floor space is identical. That extra height is a game-changer if your pallets are light and stable enough to be double-stacked, which could potentially double what you can fit inside.

Is It Cheaper to Get One 40-Foot Container Instead of Two 20-Footers?

Yes, almost without exception. A 40-foot container gives you more than twice the internal volume of a 20-footer (roughly 67 CBM vs. 33 CBM), but the ocean freight cost is typically only 20-30% more expensive—not double.

This simple math makes the 40-foot container a far better deal on a per-CBM basis. If you find your cargo is just a bit too much for a single 20-foot container, jumping up to a 40-foot is almost always the smartest financial move.

What Happens If I Mess Up My CBM and Have Too Much Cargo?

If your goods show up at the warehouse and the total CBM is more than the container's usable space, you’ve got a real problem. Everything grinds to a halt, and you're suddenly facing expensive delays trying to sort it out.

At that point, your options are all pretty bad and costly:

- Leave goods behind: You'll have to decide what part of your shipment isn't making the journey.

- Frantic repacking: You can try to repack everything on the spot to be more efficient, but that costs time and money for labour.

- Book more space: This means trying to find a larger container (like a high cube) at the last minute or booking a separate LCL shipment for the items that didn't fit.

Each of these "solutions" adds unplanned costs and throws a wrench in your supply chain schedule. This is exactly why getting your calculations right from the very beginning is so critical for a stress-free shipment.