Key Takeaways

- Chinese manufacturing quality has evolved significantly from "Made in China" to "Quality in China," with top-tier factories now implementing comprehensive quality management systems and international certifications

- Common quality issues with Chinese products include material substitution, raw material inconsistency, chemical composition problems, quality drift over production runs, and inconsistencies due to worker training gaps

- Implementing effective quality control requires a three-phase approach: pre-production measures (detailed specifications, material testing), in-production inspections, and final verification using AQL sampling methodology

- Building strong supplier relationships through clear communication strategies, bilingual documentation, regular factory visits, and quality incentive programs significantly improves manufacturing outcomes

- Technology advancements like AI-powered visual inspection systems, IoT sensors, blockchain verification, and automated quality tracking are transforming Chinese quality control, reducing defect rates by up to 40%

- Verifying proper certifications (ISO 9001, industry-specific standards) and conducting third-party inspections are crucial safeguards when sourcing products from Chinese manufacturers

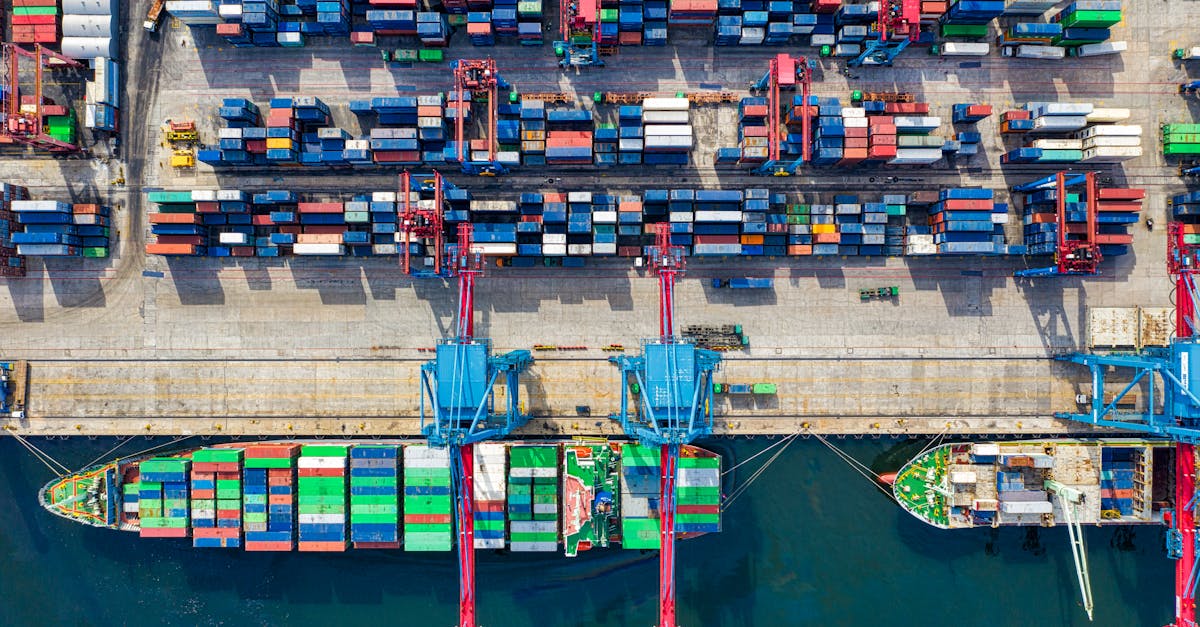

Navigating the world of Chinese manufacturing requires a robust quality control strategy. While China offers competitive pricing and vast production capabilities, ensuring consistent product quality remains a significant challenge for importers worldwide.

You'll find that effective quality control for Chinese products isn't just about final inspections—it's a comprehensive process that begins with supplier selection and continues through production monitoring. Understanding China's manufacturing ecosystem, regional specializations, and cultural business practices can dramatically impact your product quality outcomes and bottom line.

The Evolution of Quality Control in Chinese Manufacturing

From "Made in China" to "Quality in China"

China's manufacturing reputation has transformed dramatically over the past three decades. In the 1990s, "Made in China" often signified inexpensive products with questionable quality standards. Chinese factories primarily competed on price, with minimal focus on durability or performance benchmarks. Foreign buyers accepted lower quality as the trade-off for significant cost savings.

By the mid-2000s, China began its quality revolution. Government initiatives like the "Quality First" campaign pushed manufacturers to enhance standards. Premier manufacturers in Shenzhen, Shanghai, and Guangzhou started implementing international quality management systems such as ISO 9001, transforming from pure cost-cutting operations to value-added production centers.

Modern Quality Standards and Certifications

Today's Chinese manufacturing landscape features a sophisticated multi-tier quality infrastructure. Top-tier factories employ comprehensive quality management systems integrating Six Sigma methodologies, lean manufacturing principles, and automated quality verification processes. These facilities often hold multiple international certifications such as ISO 9001, ISO 14001, and industry-specific standards like IATF 16949 for automotive components.

Chinese manufacturers increasingly participate in global standards development rather than merely following established norms. Industry-specific manufacturing clusters in regions like Guangdong for electronics and Zhejiang for textiles have developed specialized quality assurance techniques tailored to their production specialties.

Technology's Role in Quality Improvement

Digital technology has revolutionized quality control in Chinese manufacturing. AI-powered visual inspection systems identify defects with 99.8% accuracy, exceeding human inspection capabilities. IoT devices throughout production lines collect real-time quality data, enabling predictive maintenance and process optimization.

Blockchain technology is being adopted by premium manufacturers to create immutable quality records across supply chains. This transparent documentation allows you to trace materials and verify testing results at every production stage. Cloud-based quality management platforms connect your design specifications directly to production floor instructions, reducing communication errors and ensuring consistency across manufacturing batches.

Remaining Challenges and Quality Variations

Despite significant progress, quality consistency varies tremendously across China's manufacturing spectrum. Tier-one manufacturers produce at world-class standards while smaller operations may still prioritize cost-cutting over quality assurance. Regional differences persist, with coastal manufacturing hubs typically maintaining higher standards than inland facilities.

Counterfeit components and unauthorized material substitutions remain persistent issues, particularly in electronics and consumer goods production. Labor shortages in manufacturing centers have created workforce stability challenges, with high turnover rates potentially affecting consistent quality implementation. Intellectual property protection has improved but continues to present risks when sharing proprietary designs or technologies with Chinese manufacturing partners.

Common Quality Issues with Chinese Products

Despite significant improvements in China's manufacturing ecosystem, several persistent quality challenges continue to impact products sourced from Chinese factories. These issues vary across industries and supplier tiers, requiring importers to implement targeted quality control strategies.

Material Quality Concerns

Material substitution represents one of the most prevalent quality issues with Chinese products. Manufacturers sometimes replace specified materials with lower-grade alternatives to reduce production costs, especially when faced with thin profit margins. For example, a factory might substitute 304-grade stainless steel with 201-grade, or use recycled plastic instead of virgin material. These substitutions often remain undetected until product performance deteriorates or safety issues emerge.

Raw material inconsistency further complicates quality control efforts. Chinese suppliers frequently source materials from multiple vendors with varying quality standards, resulting in batch-to-batch variations that affect final product integrity. This issue is particularly pronounced in industries like textiles, where fabric weight, color consistency, and tensile strength can fluctuate between production runs.

Chemical composition problems also plague certain product categories. Testing has revealed excessive levels of restricted substances in products ranging from children's toys to household items. These include:

- Lead in painted surfaces

- Phthalates in plastic components

- Formaldehyde in textile products

- Heavy metals in electronic components

Production Process Inconsistencies

Quality drift occurs frequently in Chinese manufacturing, with product standards gradually declining over successive production runs. The initial samples and early batches often meet specifications, but quality deteriorates as production continues, especially when oversight relaxes. This pattern emerges most commonly in high-volume, low-margin products where factories seek to improve profitability through subtle cost-cutting measures.

Worker training gaps contribute significantly to production inconsistencies. Many factories experience high employee turnover rates, particularly after Chinese New Year when many workers change employers. New staff often lack adequate training, resulting in assembly errors, improper machine operation, and inconsistent quality checking. These issues manifest in problems like:

- Misaligned components

- Inconsistent seam strength in garments

- Improper application of adhesives

- Incomplete quality verification steps

Equipment maintenance shortfalls further impact production consistency. Some manufacturers delay necessary machine calibration and maintenance to maximize production uptime, compromising precision and repeatability. This neglect becomes especially problematic with aging equipment that requires more frequent attention to maintain performance standards, leading to dimensional variations, surface finish irregularities, and functional inconsistencies.

Key Quality Control Standards and Certifications for Chinese Products

Chinese manufacturers adhere to various international and local quality standards that verify product safety, reliability, and compliance. Understanding these certifications helps importers assess supplier capabilities and ensure products meet market-specific requirements before they leave the factory.

ISO Certifications and Their Importance

ISO certifications serve as critical quality benchmarks for Chinese manufacturers across diverse industries. ISO 9001 establishes quality management system requirements, defining how manufacturers document processes, train staff, and implement continuous improvement. ISO 14001 focuses on environmental management systems, verifying that manufacturers minimize ecological impact through waste reduction and resource efficiency. For medical device importers, ISO 13485 certification confirms suppliers maintain specialized quality systems addressing regulatory compliance and risk management.

When evaluating Chinese suppliers, verify ISO certificates through the certification body's online database rather than accepting paper documents alone. Legitimate ISO certifications include:

- Issue date and expiration date (typically valid for three years)

- Certification body's accreditation number

- Specific scope covering your product category

- Physical address matching the actual production facility

Many leading Chinese manufacturers now pursue advanced certifications like ISO/TS 16949 for automotive components or ISO 22000 for food safety, demonstrating commitment to industry-specific quality requirements beyond basic standards.

Industry-Specific Quality Requirements

Chinese manufacturers must meet distinct certification requirements based on the target market and product category. For consumer electronics, CCC (China Compulsory Certification) serves as the domestic standard, while CE marking enables access to European markets. UL certification addresses safety requirements for the North American market, with many Shenzhen electronics manufacturers maintaining dedicated UL compliance teams.

For textiles and apparel, Chinese factories increasingly obtain:

- OEKO-TEX Standard 100 certification verifying absence of harmful substances

- BSCI (Business Social Compliance Initiative) certification addressing worker conditions

- GOTS (Global Organic Textile Standard) for organic textile processing

Medical device manufacturers in China must navigate complex regulatory frameworks including FDA registration for US exports and MDR compliance for European markets. These certifications require extensive documentation, including clinical data, risk analyses, and quality system implementation evidence.

Food product exporters adhere to HACCP (Hazard Analysis Critical Control Points) principles and often maintain BRC (British Retail Consortium) or FSSC 22000 certifications. These standards verify implementation of food safety management systems through regular third-party audits measuring contamination prevention and traceability procedures.

Certification requirements continuously evolve, with sustainability standards gaining prominence. Many Chinese manufacturers now pursue carbon footprint certifications like PAS 2050 or water usage standards like AWS (Alliance for Water Stewardship) to meet growing demands for environmentally responsible production.

Implementing Effective Quality Control Systems

Effective quality control systems transform Chinese manufacturing partnerships from potential quality risks into reliable supply chain assets. These systems involve structured protocols at every production stage, creating multiple checkpoints to catch defects before products reach customers.

Pre-Production Quality Control Measures

Pre-production quality control establishes critical quality parameters before manufacturing begins. Create detailed product specifications including engineering drawings, material requirements, and acceptable tolerance ranges to prevent misinterpretations. Review these specifications with your supplier and confirm their understanding through signed documentation or approval samples.

Evaluate raw materials through laboratory testing to verify composition, durability, and compliance with safety regulations. For electronics, component testing should include electrical performance parameters; for textiles, fiber composition and colorfastness tests; and for mechanical parts, dimensional accuracy and material strength verification.

Develop a detailed Quality Control Plan (QCP) that outlines:

- Inspection frequency at each production stage

- Sample sizes based on statistical validity (AQL levels)

- Pass/fail criteria for each quality checkpoint

- Documentation requirements for quality records

- Corrective action procedures when defects are identified

Approve production samples before authorizing full production runs. These golden samples serve as the quality benchmark throughout manufacturing and become reference standards for future production runs.

In-Production Inspection Protocols

In-production inspections catch quality issues while corrections remain cost-effective. Implement First Article Inspection (FAI) to evaluate the initial production pieces against approved samples, examining dimensions, functionality, and appearance before approving continued production.

Schedule random inspections throughout production runs using statistically valid sampling methods based on ANSI/ASQ Z1.4 standards. These inspections should occur at production milestones (20%, 50%, 80%) to identify quality drift before it affects large quantities.

Monitor critical production processes through Statistical Process Control (SPC) charts that track key quality parameters. These visual management tools help identify negative trends before they result in defects. For complex products, implement component-level inspections before assembly stages to avoid embedding defective components.

Train quality personnel to use standardized inspection tools like:

- Digital calipers for dimensional verification

- Light boxes for visual defect identification

- Functional testing equipment for performance verification

- Environmental testing chambers for durability assessment

Document all inspection results in centralized quality management systems, enabling trend analysis and continuous improvement initiatives.

Final Inspection Best Practices

Final inspections provide the last quality verification before shipment. Implement Acceptance Quality Limit (AQL) sampling methodology with appropriate inspection levels based on product risk (typically General Inspection Level II with AQL 2.5 for major defects and 4.0 for minor defects).

Create comprehensive final inspection checklists covering:

- Dimensional accuracy compared to specifications

- Functional performance under normal operating conditions

- Appearance standards including finish quality and color matching

- Packaging integrity and labeling accuracy

- Documentation completeness including user manuals and warranty cards

Verify packaging compliance with international shipping requirements and conduct carton drop tests to ensure product protection during transit. For sensitive electronics, perform specialized testing like high-potential (hi-pot) electrical safety tests and environmental stress screening.

Implement a formal product release procedure requiring quality documentation review and approval signatures before authorizing shipment. Maintain detailed records of final inspection results including photos of defects identified and corrective actions implemented.

Consider third-party inspection services for objective quality verification, particularly for initial orders or when working with new suppliers. These independent inspections provide unbiased quality assessments following internationally recognized standards and protocols.

Working with Chinese Manufacturers for Better Quality

Establishing effective partnerships with Chinese manufacturers demands strategic approaches that go beyond basic supplier-buyer interactions. Your ability to navigate cultural differences and implement systematic communication channels directly impacts product quality outcomes and manufacturing consistency.

Communication Strategies That Work

Clear communication forms the backbone of successful quality management with Chinese manufacturing partners. Implementing technical documentation with visual aids like diagrams, photos, and videos significantly reduces misinterpretations compared to text-only instructions. Create bilingual specification sheets with measurements in both metric and imperial systems, and include tolerance ranges for each critical parameter.

Digital collaboration tools like WeChat, DingTalk, and enterprise resource planning (ERP) systems enable real-time communication across time zones. These platforms facilitate quick problem-solving and maintain detailed conversation records for future reference. For complex technical discussions, schedule video conferences with screen-sharing capabilities to demonstrate quality expectations visually.

Regular factory visits (2-4 times annually) strengthen relationships and provide opportunities to observe production processes firsthand. During these visits, bring physical samples of acceptable and unacceptable products to reinforce quality standards. Consider employing a bilingual quality representative based in China who understands both your technical requirements and local manufacturing practices.

When communicating quality issues, focus on specific measurable parameters rather than subjective assessments. For example, instead of stating "poor finish quality," specify "surface roughness exceeds 5μm in three measured locations."

Building Long-Term Quality-Focused Relationships

Developing strategic partnerships with Chinese manufacturers yields superior quality outcomes compared to transactional relationships. Implement graduated quality incentive programs that reward consistent quality improvements with increased order volumes or premium pricing. These incentives align your quality goals with your supplier's business objectives.

Joint investment in quality improvement initiatives, such as funding specialized testing equipment or training programs, demonstrates commitment to the relationship while enhancing capabilities. Share market feedback and customer insights about product performance to help manufacturers understand how their quality impacts your business outcomes.

Recognize and celebrate quality achievements through supplier recognition programs or periodic performance reviews. Many Chinese manufacturers respond positively to public acknowledgment of their quality excellence, especially when it enhances their reputation with other potential clients.

Maintain reasonable expectations during Chinese holidays like Chinese New Year and Golden Week, when production capacity and workforce availability fluctuate significantly. Plan quality-critical production runs outside these periods, and schedule additional inspections for post-holiday production to catch potential issues from newly hired workers.

Gradual transfer of technical knowledge through documented training sessions builds manufacturer capability and independence in quality management. This approach transforms your relationship from constant oversight to collaborative quality development, creating a more sustainable long-term partnership focused on continuous improvement.

Technology Advancements in Chinese Quality Control

Chinese manufacturers are rapidly adopting cutting-edge technologies to enhance quality control processes. These technological innovations have transformed traditional inspection methods into sophisticated, data-driven systems that identify defects with unprecedented accuracy and efficiency.

Automation and Quality Improvement

Automation technologies have revolutionized quality control in Chinese manufacturing facilities. Robotic inspection systems equipped with high-definition cameras can detect microscopic defects invisible to the human eye, examining thousands of units per hour with consistent accuracy. Machine vision systems use AI algorithms to identify variations in color, texture, and dimensions with precision measured in microns.

Many Chinese factories have implemented fully automated production lines with integrated quality checkpoints that perform real-time measurements and verification. These systems can automatically reject defective products without human intervention, reducing labor costs while improving detection rates by 35-40% compared to manual inspection methods.

3D scanning and digital modeling technologies enable manufacturers to compare finished products against original CAD designs, identifying dimensional deviations as small as 0.01mm. In industries like electronics and precision components, these systems verify critical specifications that directly impact product functionality and reliability.

Quality Tracking Systems

Digital quality tracking systems have replaced paper-based documentation throughout China's manufacturing sector. Cloud-based quality management platforms allow real-time data collection and analysis across multiple production facilities, creating comprehensive digital trails for every product batch.

Blockchain technology is increasingly used to create tamper-proof records of quality inspections and material sourcing, particularly valuable for industries with stringent compliance requirements like pharmaceuticals and aerospace. These systems provide immutable verification chains that track products from raw materials through production to final delivery.

IoT sensors embedded throughout production environments continuously monitor critical parameters like temperature, humidity, and air quality that can affect product integrity. Chinese manufacturers utilize these networks to collect over 500 million data points daily in some facilities, enabling predictive quality analytics that identify potential issues before defects occur.

Mobile inspection applications have equipped quality personnel with powerful tools to document findings directly from the factory floor. These apps capture photos, measurements, and test results while automatically generating inspection reports and issuing alerts when specifications fall outside acceptable parameters.

Advanced data analytics platforms process quality metrics from multiple sources to identify correlations between production variables and defect rates. Chinese manufacturers leverage these insights to optimize processes, reducing defect rates by an average of 23% within six months of implementation.

Conclusion

Quality control for Chinese products has evolved dramatically from basic inspections to sophisticated technological systems. Your success hinges on implementing a comprehensive approach that begins with supplier selection and continues through production monitoring.

Leveraging technology like AI-powered inspections and IoT sensors while maintaining clear communication with manufacturers will significantly improve your outcomes. Remember that regional specializations matter and understanding cultural business practices is essential for maintaining consistent quality.

The manufacturing landscape in China continues to transform with sustainability standards gaining importance alongside traditional quality metrics. By establishing thorough quality control systems with pre-production checks through final inspections you'll maximize your investment and minimize risks.

With the right quality control strategy your Chinese manufacturing partnerships can deliver exceptional value with consistent quality that meets global standards.

Frequently Asked Questions

Why is quality control important when manufacturing in China?

Quality control is crucial when manufacturing in China because despite competitive pricing and extensive production capabilities, maintaining consistent product quality remains a major challenge. Effective quality control involves a comprehensive process from supplier selection to ongoing production monitoring, not just final inspections. Understanding China's manufacturing landscape, including regional specializations and cultural business practices, significantly impacts product quality and overall profitability.

How has quality control in Chinese manufacturing evolved over time?

Chinese manufacturing has transformed dramatically since the 1990s, evolving from a "Made in China" reputation associated with low-quality products to today's "Quality in China" mindset. This shift has been driven by government initiatives and widespread adoption of international quality management systems. Leading manufacturing centers like Shenzhen and Shanghai have embraced sophisticated quality management approaches including Six Sigma methodologies and automated verification processes.

What are common quality issues in Chinese manufacturing?

Common quality issues include material substitution, raw material inconsistency, and chemical composition problems. Production process inconsistencies are also prevalent, such as quality drift over successive production runs and worker training gaps due to high turnover rates. These issues vary across different manufacturing tiers, with additional challenges including counterfeit components and labor stability concerns.

What quality control standards do Chinese manufacturers follow?

Chinese manufacturers increasingly adhere to international standards, particularly ISO certifications. Many also comply with industry-specific requirements relevant to their product categories. As sustainability becomes more important, manufacturers are pursuing certifications related to carbon footprint reduction and water usage. These standards help ensure products meet global compliance requirements and customer expectations.

How is technology improving quality control in Chinese manufacturing?

Technology has revolutionized quality control in Chinese manufacturing through AI-powered inspections, IoT devices for real-time monitoring, robotic inspection systems, and machine vision. These innovations have significantly improved detection rates and consistency. Digital quality tracking systems and blockchain technology enhance documentation and compliance, while IoT sensors continuously monitor critical parameters to ensure product integrity throughout the manufacturing process.

What should a good quality control strategy include?

A good quality control strategy should include pre-production measures like material verification and prototype testing, regular in-production inspections, and comprehensive final inspection protocols. Clear communication, regular factory visits, and employing bilingual quality representatives are essential for effective partnerships with Chinese manufacturers. The strategy should focus on continuous improvement and address both process and product quality metrics.

How can companies establish effective partnerships with Chinese manufacturers?

Companies can establish effective partnerships through clear communication, regular factory visits, and involving bilingual quality representatives to bridge cultural and language gaps. Developing detailed quality specifications, establishing measurable standards, and creating accountability frameworks are crucial. Building relationships based on mutual respect and understanding cultural business practices contributes to sustainable partnerships focused on continuous quality improvement.

Are there regional differences in manufacturing quality within China?

Yes, significant regional differences exist in manufacturing quality within China. Coastal regions like Shenzhen, Shanghai, and Guangzhou typically maintain higher quality standards due to longer manufacturing histories and greater international exposure. Inland manufacturing centers may offer cost advantages but sometimes with quality trade-offs. Understanding these regional specializations can help companies select the right manufacturing partners for their specific needs.