Key Takeaways

- Effective inventory management for China dropshipping requires real-time stock tracking, accurate demand forecasting, and strong supplier relationships to overcome the 7-30 day shipping times and communication barriers.

- Communication challenges with Chinese suppliers include significant time zone differences (12+ hours), language barriers, and cultural differences—especially during holidays like Chinese New Year when operations may shut down for weeks.

- Quality control remains a persistent challenge, requiring detailed product specification sheets, sample requests, and potentially third-party inspection services to maintain consistent standards.

- Specialized inventory management software like Oberlo, DSers, and CJDropshipping provides crucial features such as multi-channel synchronization, automated order routing, and supplier management tools with translation capabilities.

- Setting strategic reorder points and safety stock levels (15-20% buffer for best-sellers, 5-10% for slow-moving items) helps balance the risk of stockouts against excess inventory costs.

- Seasonal inventory planning requires ordering 60-90 days before anticipated demand peaks, implementing data analytics for accurate forecasting, and developing backup supplier relationships to reduce stockout risks.

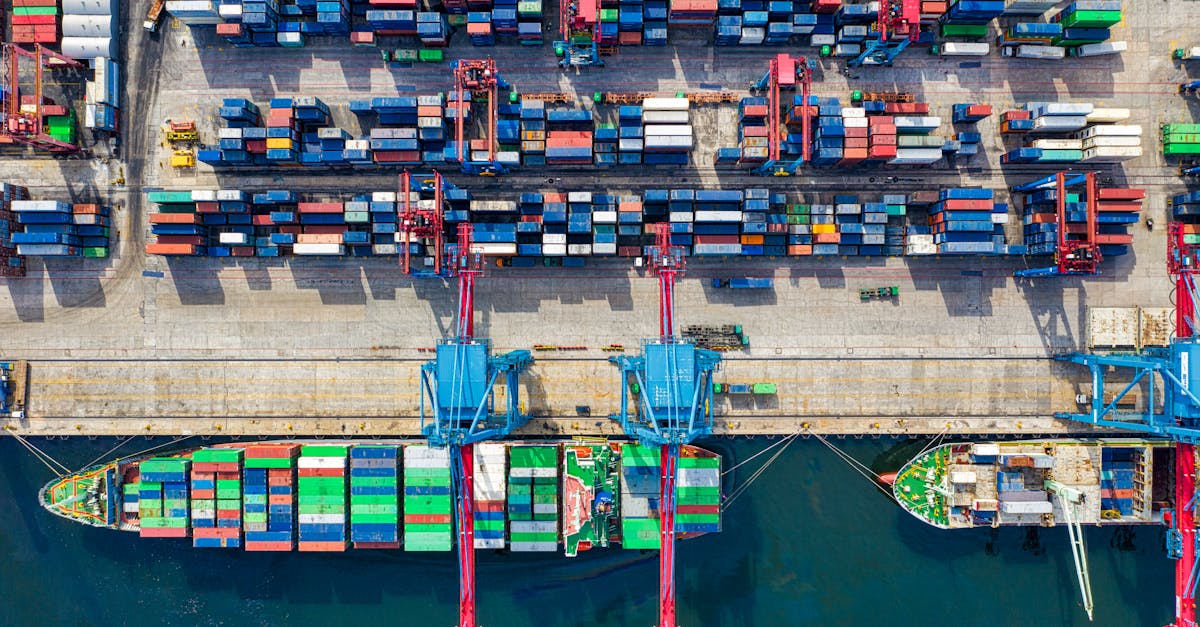

Managing inventory for your China dropshipping business can feel like walking a tightrope. You're balancing customer expectations against long shipping times, while trying to keep costs down and profits up. Without effective inventory management, you risk stockouts, overstocking, and disappointed customers.

In today's competitive e-commerce landscape, mastering inventory management for your China dropshipping operation isn't just helpful—it's essential for survival. You'll need strategies that account for extended shipping times, variable supplier reliability, and fluctuating demand. The good news? With the right systems in place, you can transform this challenge into a competitive advantage.

What Is Inventory Management for China Dropshipping

Inventory management for China dropshipping refers to the process of monitoring and controlling the products available from Chinese suppliers that you sell through your online store. Unlike traditional retail models, dropshippers don't physically store inventory—instead, they partner with Chinese suppliers who ship products directly to customers.

Effective China dropshipping inventory management involves:

- Stock level tracking: Monitoring available inventory at your Chinese suppliers' warehouses to prevent selling out-of-stock items

- Order processing: Coordinating with suppliers to ensure timely fulfillment of customer orders

- Demand forecasting: Analyzing sales data to predict which products will sell, helping suppliers prepare adequate stock

- Supplier relationship management: Maintaining strong communication with Chinese manufacturers to address inventory issues quickly

China dropshipping inventory management differs from traditional inventory systems primarily because you're dealing with products located thousands of miles away in Chinese warehouses. This geographical distance creates unique challenges, including extended shipping times (typically 7-30 days), communication barriers with Chinese suppliers, and limited visibility into actual warehouse conditions.

The core goal of inventory management in this context is minimizing risk while maximizing profit. When managed correctly, you'll reduce instances of selling unavailable products, avoid customer disappointment, and maintain positive reviews—all critical factors for e-commerce success.

The Importance of Effective Inventory Management in Dropshipping

Effective inventory management forms the backbone of successful dropshipping operations, particularly when sourcing products from China. Without proper inventory control systems, your dropshipping business faces significant risks that can impact both profitability and customer satisfaction.

When you implement robust inventory management practices, you're able to maintain optimal stock levels, reduce operational costs, and deliver products to customers within expected timeframes. This balance is especially critical in China dropshipping, where extended shipping distances create additional complexities in the supply chain.

Poor inventory management leads to numerous operational challenges: stockouts disappoint customers and result in lost sales, while overstocking ties up capital in excess inventory and increases storage costs. These issues are magnified in the China dropshipping model due to longer lead times and international shipping considerations.

The most successful dropshipping businesses treat inventory management as a strategic advantage rather than an operational burden. By focusing on inventory optimization, you're positioned to scale your business more effectively, reduce costly errors, and create more predictable customer experiences despite the inherent challenges of sourcing products from overseas suppliers.

Key Challenges of Inventory Management with Chinese Suppliers

Managing inventory with Chinese suppliers presents several unique obstacles for dropshipping businesses. These challenges affect every aspect of your supply chain and can impact customer satisfaction if not properly addressed.

Communication Barriers and Time Zone Differences

Communication barriers create significant hurdles when managing inventory with Chinese suppliers. The 12+ hour time difference between North America or Europe and China means your business day rarely overlaps with your supplier's working hours. Emails sent during your morning might not receive responses until the next day, extending decision-making cycles by 24-48 hours. Language differences further complicate interactions, with technical product details or inventory specifications often getting misinterpreted.

Many Chinese suppliers communicate through platforms like WeChat or Alibaba messaging rather than email, requiring you to adapt to different communication systems. Cultural differences in business practices also impact inventory management—Chinese holidays like Chinese New Year can shut down operations for weeks, requiring advanced planning for adequate stock levels during these periods.

Quality Control Concerns

Quality control issues present persistent challenges when dropshipping from China. Without physical inspection of products before they reach customers, you're relying on supplier consistency that isn't guaranteed. Product specifications often vary between batches, resulting in customer complaints about items not matching website descriptions or photos.

Chinese suppliers frequently substitute materials or components without notice, especially during supply chain disruptions or cost increases. Establishing reliable quality standards requires implementing systematic approaches like requesting product samples before bulk orders, creating detailed product specification sheets with acceptable tolerances, and developing relationships with inspection services that can check goods before shipping. Quality issues directly impact inventory management by increasing return rates and necessitating higher safety stock levels to account for potential defective items.

Shipping and Logistics Complexities

Shipping and logistics complexities significantly impact inventory management when dropshipping from China. Shipping times vary dramatically—from 7-15 days for premium shipping methods to 30-60 days for standard options—making accurate delivery promises to customers challenging. Customs delays introduce additional unpredictability, with products occasionally held for inspection for days or weeks without notice.

Tracking information is often incomplete or unreliable during certain shipping phases, particularly once packages transfer from Chinese carriers to local postal services. Shipping costs fluctuate based on fuel prices, container availability, and seasonal demand, affecting your pricing strategy and profit margins. International shipping regulations change frequently, with certain products suddenly facing import restrictions or additional documentation requirements. These logistics uncertainties require maintaining higher buffer stock levels and developing contingency plans for shipping disruptions, adding complexity to your inventory management system.

Best Inventory Management Software for China Dropshipping

Selecting the right inventory management software is crucial for streamlining your China dropshipping operations and overcoming the unique challenges of cross-border e-commerce. These specialized tools help automate inventory tracking, sync stock levels across multiple platforms, and facilitate seamless communication with Chinese suppliers.

Features to Look for in Dropshipping Inventory Tools

Effective dropshipping inventory management tools offer specific capabilities that address the complexities of sourcing from China. When evaluating software options, prioritize these essential features:

- Real-time inventory synchronization across multiple sales channels to prevent overselling and maintain accurate stock levels

- Automated order routing that instantly sends customer orders to the appropriate Chinese suppliers

- Supplier management tools with translation capabilities to overcome language barriers and streamline communication

- Shipping and tracking integration that monitors packages from Chinese warehouses to customer destinations

- Demand forecasting algorithms that analyze sales patterns to predict inventory needs and reduce stockouts

- Custom alerts and notifications for low stock levels, delayed shipments, or supplier issues

- Currency conversion features that handle RMB-to-local currency calculations automatically

- Integration capabilities with popular e-commerce platforms like Shopify, WooCommerce, and Amazon

- Mobile accessibility to manage inventory on the go and respond quickly to time-sensitive issues

Top Software Solutions for 2023

These leading inventory management solutions offer specialized features for China dropshipping operations:

- Oberlo: Seamlessly integrates with Shopify stores and connects directly with AliExpress suppliers. Oberlo automatically updates product information and inventory levels, making it ideal for beginners entering the China dropshipping market.

- DSers: Provides advanced order management for AliExpress dropshipping with bulk ordering capabilities. DSers allows you to process up to 100 orders with a single click and maintains accurate inventory tracking across multiple stores.

- CJDropshipping: Offers end-to-end inventory management with warehousing facilities in China. Their platform includes product sourcing, quality inspection, inventory storage, and fulfillment services specifically designed for dropshippers.

- Inventory Source: Delivers automated inventory and order management with over 230 supplier integrations, including many Chinese manufacturers. Their system provides daily inventory updates and automatic order routing.

- Orderhive: Features comprehensive inventory management with multi-channel capabilities and specialized tools for international suppliers. Orderhive includes purchase order management and supplier performance analytics.

- ShipStation: Excels in order processing and shipping management with robust integration options. Their platform simplifies label creation, tracking updates, and customer communication for international shipments.

- Ecomdash: Specializes in inventory synchronization across marketplaces with built-in supplier management tools. Ecomdash automatically adjusts for time zone differences when communicating with Chinese suppliers.

- Cin7: Provides advanced inventory control with built-in B2B portals for supplier collaboration. Their system includes EDI capabilities and automation workflows specifically designed for international supply chains.

Strategies to Optimize Your China Dropshipping Inventory

Effective inventory optimization strategies are essential for China dropshipping success. These approaches help balance customer satisfaction with operational efficiency while navigating the unique challenges of sourcing from Chinese suppliers.

Forecasting Demand Accurately

Accurate demand forecasting forms the foundation of effective inventory management in China dropshipping. Analyze historical sales data across 12-24 months to identify seasonal patterns, growth trends, and product lifecycle stages. Incorporate external factors like market trends, competitor activities, and planned marketing campaigns into your forecasts. Tools like Google Trends provide insights into search volume patterns, while inventory management platforms offer built-in analytics to detect emerging sales patterns. Start with simple moving averages for new products and gradually implement more sophisticated forecasting methods like exponential smoothing or machine learning algorithms as your data set grows.

Building Strong Supplier Relationships

Strong supplier relationships directly impact inventory reliability and business success in China dropshipping. Establish clear communication channels with your Chinese suppliers using platforms like WeChat or Alibaba Trade Assurance that offer translation capabilities. Schedule regular check-ins at times that accommodate the 8-12 hour time difference, and document all agreements about lead times, quality standards, and packaging requirements. Develop contingency plans with backup suppliers for your top-selling products to mitigate stockout risks. Visiting suppliers in person during trade shows like Canton Fair builds trust and opens doors to better pricing, priority production slots, and insider information about upcoming inventory changes.

Setting Reorder Points and Safety Stock Levels

Strategic reorder points and safety stock levels protect your business from stockouts while preventing excess inventory. Calculate your optimal reorder point by multiplying your average daily sales by lead time (typically 2-4 weeks for Chinese suppliers) and adding safety stock. Determine safety stock levels based on demand variability, lead time consistency, and product importance—allocate higher safety stock (15-20% above normal stock) for best-selling items and lower levels (5-10%) for slow-moving products. Implement automated inventory alerts through your management software to trigger purchases when stock reaches reorder thresholds. Review and adjust these levels quarterly to reflect changing sales patterns, supplier performance, and seasonal fluctuations.

How to Handle Seasonal Inventory Fluctuations

Seasonal demand patterns significantly impact dropshipping businesses sourcing from China. Holiday shopping surges, back-to-school seasons, and summer vacation periods create predictable yet challenging inventory cycles that require strategic planning to manage effectively.

Identifying Seasonal Trends in Your Niche

Seasonal trend identification starts with analyzing your historical sales data across multiple timeframes. Extract year-over-year patterns by examining monthly sales reports for at least two consecutive years, identifying clear spikes and dips in product demand. Supplement this analysis with market research tools like Google Trends to visualize interest fluctuations for your product categories.

Look for correlation patterns between specific products and calendar events—winter apparel sales typically surge in October-November, while outdoor recreational items peak before summer. Industry-specific publications and trade associations often publish seasonal forecasts that provide additional context for your planning.

Planning Inventory Orders in Advance

Advanced inventory ordering requires calculating lead times accurately for seasonal planning. Add your supplier's production time (typically 7-21 days for custom products) to shipping duration (15-30 days for standard shipping from China) plus customs clearance (3-7 days). For holiday seasons, place orders 60-90 days before anticipated demand peaks to accommodate these extended timelines.

Implement a rolling forecast system that updates inventory projections monthly based on real-time sales data. Create a seasonal ordering calendar with clearly marked deadlines for each product category, accounting for Chinese holidays like Chinese New Year when factories close for weeks. Consider negotiating with suppliers to secure production slots during peak manufacturing periods and explore partial shipment arrangements to maintain flexibility.

Using Data Analytics for Seasonal Forecasting

Data-driven forecasting enhances seasonal inventory management through advanced analytics techniques. Implement time series analysis models that decompose historical sales data into trend, seasonal, and cyclical components, revealing underlying patterns. Moving average calculations smooth out random fluctuations while highlighting true seasonal cycles.

Integrate external factors into your models, including:

- Economic indicators like consumer confidence indexes

- Weather pattern predictions for seasonal products

- Social media trend monitoring for emerging demand shifts

- Competitor pricing and promotion schedules

Cloud-based analytics platforms like Tableau and Power BI visualize seasonal patterns through interactive dashboards, while machine learning algorithms continuously improve forecast accuracy by incorporating new sales data. These tools can identify micro-seasons—short-term demand fluctuations within broader seasonal trends—allowing for more precise inventory planning.

Creating Buffer Stock Strategies for Peak Seasons

Buffer stock management balances the risks of stockouts against excess inventory costs during seasonal peaks. Calculate optimal buffer levels using the formula: Buffer Stock = (Maximum Daily Usage × Maximum Lead Time) − (Average Daily Usage × Average Lead Time).

For high-margin seasonal products, maintain larger buffers (30-45 days of supply) to prevent lost sales opportunities. For lower-margin items, keep tighter buffers (10-15 days) to minimize carrying costs. Implement tiered buffer strategies by categorizing products into A/B/C classifications based on profit contribution and seasonal volatility.

Develop relationships with multiple suppliers for critical seasonal items, creating supply redundancy that reduces stockout risks. Negotiate consignment arrangements where possible, allowing you to maintain inventory access without immediate payment until items sell through your platform.

Managing Excess Inventory After Peak Seasons

Post-season inventory management prevents capital tie-up through strategic liquidation techniques. Create a tiered discount schedule that gradually increases markdowns based on time elapsed since the season ended—10% after two weeks, 25% after one month, and up to 50% for remaining stock after two months.

Bundle slow-moving seasonal items with complementary year-round products to maintain value perception while clearing inventory. Explore flash sale platforms like Temu or AliExpress Flash Deals to quickly liquidate remaining stock without disrupting your main store's pricing structure.

For products with multi-year shelf life, implement controlled storage strategies with climate-controlled warehousing for sensitive items. Calculate the carrying costs against potential future season profits to determine optimal retention quantities. Create detailed inventory aging reports to track seasonal items and establish automatic review triggers when products reach predetermined age thresholds.

Reducing Risks of Stockouts and Overstock Situations

Inventory imbalances pose significant risks to dropshipping businesses working with Chinese suppliers. Effective risk management strategies help maintain optimal inventory levels, preventing both stockouts that disappoint customers and overstock situations that tie up capital. Implementing these targeted approaches enables you to navigate the unique challenges of China-based supply chains while maintaining profitability.

Implementing Real-Time Inventory Tracking

Real-time inventory tracking transforms how you monitor product availability across your dropshipping business. Advanced inventory management systems integrate directly with supplier databases, providing up-to-the-minute stock levels without manual verification. These systems alert you when inventory falls below predefined thresholds, giving you crucial lead time to reorder before stockouts occur.

Key benefits of real-time tracking include:

- Instant visibility into stock fluctuations across multiple suppliers

- Automated notifications when products reach critical inventory levels

- Cross-platform synchronization between your storefront and supplier inventories

- Historical data collection for identifying inventory trends and patterns

Modern tracking solutions like Cin7 and Orderhive offer specialized features for China dropshipping operations, including supplier portal access that accommodates time zone differences.

Developing Supplier Backup Strategies

Relying on a single supplier creates vulnerability in your dropshipping supply chain. Developing backup supplier relationships provides critical redundancy when your primary source experiences production delays, quality issues, or inventory shortages. This multi-supplier approach ensures continuous product availability even when individual vendors face challenges.

Effective backup strategies include:

- Identifying 2-3 alternate suppliers for your top-selling products

- Pre-qualifying backup vendors through small test orders

- Maintaining current pricing agreements with all potential suppliers

- Creating standardized product specifications to ensure consistency between suppliers

During Chinese holidays like Lunar New Year when many factories close for weeks, having established backup suppliers prevents extended stockout periods that damage customer relationships and revenue streams.

Utilizing Just-in-Time Inventory Approaches

Just-in-time (JIT) inventory approaches minimize overstock risks while ensuring product availability. This methodology involves ordering inventory precisely when needed based on actual customer demand rather than speculative forecasting. For China dropshipping operations, JIT requires careful timing adjustments to account for extended shipping timeframes.

To implement JIT effectively:

- Calculate precise lead times for each supplier and product category

- Establish order triggers based on current sales velocity and remaining inventory

- Create rolling forecasts that update continuously with new sales data

- Maintain transparent communication channels with suppliers about upcoming needs

The JIT approach is particularly valuable for higher-priced items where overstock situations represent significant tied-up capital, while cheaper, fast-moving products might benefit from slightly larger inventory buffers.

Setting Dynamic Par Levels

Dynamic par levels adapt inventory thresholds based on changing market conditions, seasonal factors, and supplier capabilities. Unlike static inventory minimums, dynamic par levels automatically adjust to reflect current sales patterns, preventing both stockouts during demand surges and overstocking during slower periods.

When implementing dynamic par levels:

- Segment products by sales velocity, profit margin, and supplier reliability

- Establish different thresholds for various product categories

- Program regular recalculations based on recent sales history

- Factor in upcoming promotions that might impact demand

High-performing dropshipping businesses review and adjust par level algorithms quarterly to reflect changing market conditions and customer preferences, particularly when sourcing from Chinese suppliers where lead times fluctuate seasonally.

Integrating Your Inventory Management with E-commerce Platforms

Seamless integration between your inventory management system and e-commerce platforms transforms your China dropshipping operation into a well-oiled machine. Proper integration eliminates manual data entry, reduces errors, and ensures your customers see accurate product availability across all sales channels.

Shopify Integration Best Practices

Shopify's robust ecosystem supports multiple inventory management solutions for China dropshipping. Connect your inventory system to Shopify through native apps like Oberlo or DSers to automatically sync stock levels. Use the Shopify API to establish real-time communication between your inventory management software and store, ensuring product availability updates instantly when suppliers make changes.

Create dedicated product tags or collections for items from different Chinese suppliers to organize your inventory more effectively. Configure automated notifications to alert you when products reach low stock thresholds, giving you ample time to contact suppliers before stockouts occur.

WooCommerce and WordPress Solutions

WooCommerce offers flexible integration options for dropshippers sourcing from China. Install specialized plugins like WooCommerce Dropshipping or AliDropship to connect your WordPress store directly with inventory management systems. These plugins automatically update stock levels, process orders, and communicate with suppliers.

Set up custom product attributes to track supplier information, processing times, and shipping details directly within your WooCommerce dashboard. Utilize WP REST API endpoints to create custom integrations between your inventory system and WordPress site, especially useful for businesses with unique workflow requirements.

Amazon and eBay Marketplace Connections

Amazon and eBay require precise inventory management to maintain good seller metrics and prevent account suspensions. Connect your inventory system to these marketplaces using multi-channel solutions like Ecomdash or Sellbrite that offer specialized features for China dropshipping operations. These tools automatically adjust inventory levels across platforms when sales occur on any channel.

Implement buffer stock settings specifically for marketplace listings to account for the stricter performance requirements on these platforms. Configure automated repricing tools to maintain competitiveness while considering your current inventory levels and supplier availability.

Multi-Channel Integration Strategies

Multi-channel selling demands sophisticated inventory synchronization to prevent overselling across platforms. Implement a centralized inventory hub like Cin7 or TradeGecko that acts as the single source of truth for all your product quantities. Set channel-specific rules for inventory allocation, giving priority to platforms with higher conversion rates or profit margins.

Create automated workflows that update inventory across all connected platforms when receiving new stock information from Chinese suppliers. Schedule regular inventory audits to identify and correct any synchronization issues before they impact customer orders. Maintain separate buffer thresholds for each sales channel based on their unique ordering patterns and processing times.

Conclusion

Mastering inventory management is your secret weapon in China dropshipping success. By implementing the right software tools and developing strategic supplier relationships, you'll transform potential challenges into competitive advantages.

Smart forecasting techniques and dynamic inventory thresholds protect your business from costly stockouts while preventing capital tie-up in excess inventory. When you integrate these systems across all your sales channels, you create a seamless operation that scales effortlessly.

Remember that effective inventory management isn't just about keeping track of products—it's about creating reliable customer experiences despite geographical distances. Your ability to deliver consistently will set you apart in the crowded e-commerce landscape and build the foundation for long-term dropshipping success.

Frequently Asked Questions

What is inventory management in China dropshipping?

Inventory management in China dropshipping is the process of monitoring and controlling products sourced from Chinese suppliers who ship directly to customers. It involves tracking stock levels, processing orders, forecasting demand, and managing supplier relationships—all while dealing with unique challenges like extended shipping times and communication barriers due to geographical distance.

Why is effective inventory management important for dropshipping success?

Effective inventory management is the backbone of successful dropshipping operations. It helps maintain optimal stock levels, reduces operational costs, and ensures timely delivery. Poor management leads to stockouts (lost sales) or overstocking (increased costs). Businesses that master inventory management gain a strategic advantage, allowing them to scale effectively and create consistent customer experiences.

What are the main challenges of managing inventory with Chinese suppliers?

The main challenges include communication barriers due to language and time zone differences, quality control concerns, longer shipping times, and logistics complexities. These challenges often require maintaining higher buffer stock levels and developing contingency plans to prevent disruptions in your supply chain and maintain customer satisfaction.

What features should I look for in inventory management software?

Look for real-time inventory synchronization across all sales channels, automated order routing to suppliers, stock level alerts, demand forecasting capabilities, supplier management tools, and comprehensive reporting. The right software should integrate seamlessly with your e-commerce platform and help streamline communication with Chinese suppliers.

What are the top inventory management software options for China dropshipping?

Top options include Oberlo (Shopify-specific), DSers (AliExpress integration), CJDropshipping (all-in-one solution), Inventory Source (automation tools), and ShipStation (shipping management). Each offers different features to enhance efficiency and improve communication with suppliers, so choose based on your specific business needs and platform.

How can I forecast demand accurately for my dropshipping business?

Accurately forecast demand by analyzing historical sales data, identifying seasonal trends, monitoring market conditions, and leveraging analytics tools. Consider external factors like holidays, marketing campaigns, and competitor actions. Regularly review and adjust your forecasts based on actual performance to continuously improve accuracy.

What is the Just-in-Time (JIT) inventory approach?

Just-in-Time is an inventory strategy where products are ordered from suppliers only when needed to fulfill customer orders, minimizing overstock risks. This approach reduces carrying costs and storage needs but requires excellent supplier relationships and accurate demand forecasting. For China dropshipping, JIT must be modified to account for longer shipping times.

How do I handle seasonal inventory fluctuations?

Handle seasonal fluctuations by identifying historical patterns, planning orders well in advance, communicating early with suppliers about expected volume increases, maintaining flexible inventory thresholds, and implementing targeted marketing strategies. Consider pre-stocking popular seasonal items with domestic suppliers to avoid extended shipping times during peak seasons.

How can I integrate inventory management with multiple e-commerce platforms?

Use centralized inventory management software that synchronizes stock levels across all sales channels in real-time. Implement automated rules for inventory allocation, establish consistent SKU naming conventions, regularly audit synchronization accuracy, and set buffer stock levels to prevent overselling. This approach eliminates manual updates and reduces errors.

What are dynamic par levels and why are they important?

Dynamic par levels are inventory thresholds that automatically adjust based on changing market conditions, seasonal demands, and sales velocity. They're important because they help optimize inventory by ensuring you maintain appropriate stock levels during both high and low demand periods, reducing both stockout risks and excess inventory costs.