As businesses worldwide face mounting pressure to reduce their environmental impact, green logistics has emerged as a critical component of corporate sustainability strategies. By reimagining supply chains with eco-friendly practices, companies aren't just helping the planet—they're often boosting their bottom line through improved efficiency and consumer goodwill.

When you implement sustainable logistics solutions, you're addressing multiple environmental challenges simultaneously. From reducing carbon emissions through optimized transportation routes to decreasing waste with recyclable packaging materials, every aspect of the supply chain offers opportunities for meaningful ecological improvements. These changes not only satisfy growing consumer demand for environmentally responsible products but also help companies comply with increasingly stringent environmental regulations.

Understanding Green Logistics and Sustainability

Green logistics integrates environmental considerations into traditional supply chain management practices. It's an approach that balances operational efficiency with environmental responsibility, minimizing ecological impacts across the entire logistics network. As sustainability becomes a business imperative, understanding the fundamentals of green logistics helps companies develop strategies that benefit both their bottom line and the planet.

Green logistics encompasses several key components:

- Transport optimization: Reducing fuel consumption through route planning and vehicle selection

- Warehouse sustainability: Implementing energy-efficient facilities with renewable power sources

- Packaging improvements: Using recyclable materials and minimizing packaging waste

- Reverse logistics: Managing product returns and end-of-life recycling efficiently

- Supply chain visibility: Tracking environmental metrics throughout the logistics network

The environmental benefits of green logistics extend beyond simply reducing carbon emissions. Companies that embrace sustainable practices often experience improved resource efficiency, waste reduction, and enhanced compliance with environmental regulations. These benefits translate to operational improvements, cost savings, and stronger brand positioning among environmentally conscious consumers.

Green logistics isn't merely a trend—it's becoming central to competitive business strategy. Companies like Unilever, IKEA, and Amazon have established ambitious sustainability goals that significantly reshape their logistics operations. By making sustainability a strategic priority, these companies are driving industry-wide changes in how products move from manufacturers to consumers.

The Environmental Impact of Traditional Logistics

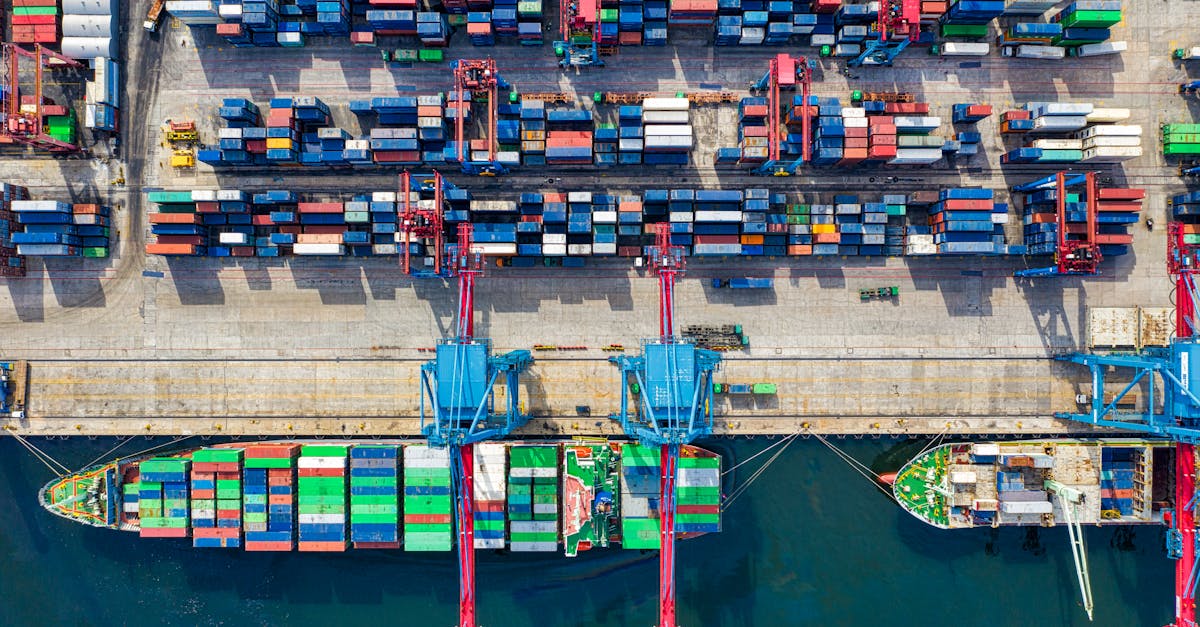

Traditional logistics operations contribute significantly to global environmental degradation through various channels. The conventional movement of goods across global supply chains creates substantial ecological pressures that call for urgent attention and sustainable alternatives.

Carbon Footprint of Global Supply Chains

The carbon footprint of global supply chains represents one of the most pressing environmental challenges of our time. Transportation activities alone account for approximately 24% of global CO2 emissions from fuel combustion, with freight transport responsible for about 40% of that total. Long-haul trucking, air freight, and container shipping release massive amounts of greenhouse gases—a single large container ship can emit as much sulfur oxide as 50 million cars. Major corporations like Walmart and Maersk have identified that logistics-related activities contribute to over 80% of their total emissions, highlighting the scale of the problem across industries.

The emissions issue extends beyond just CO2, including particulate matter, nitrogen oxides, and other air pollutants that contribute to respiratory diseases and environmental degradation. In urban areas, last-mile delivery vehicles generate 25-35% of transport-related pollution despite representing only 2-5% of urban traffic. These emissions directly impact air quality, accelerate climate change, and create economic costs through health impacts and environmental damage estimated at $4.6 trillion annually.

Resource Depletion and Waste Generation

Traditional logistics operations consume vast amounts of natural resources and generate significant waste throughout the supply chain. Packaging waste alone accounts for approximately 30% of total municipal solid waste in developed countries, with an estimated 80 million tons of packaging waste produced annually in the United States. Non-biodegradable materials such as plastic packaging, pallets, and shipping materials often end up in landfills, with only 14% of plastic packaging recycled globally.

The resource intensity of conventional logistics extends to warehouse operations, which consume substantial energy—typically 25 kWh per square meter annually—and water resources. Inefficient inventory management leads to product obsolescence and waste, with retail and grocery sectors disposing of $15 billion worth of unsold inventory annually in the US alone. The single-use mentality prevalent in traditional logistics creates a linear "take-make-dispose" model that accelerates resource depletion, particularly of fossil fuels, timber, and water. E-commerce returns represent another significant source of waste, with 5 billion pounds of returned merchandise ending up in landfills each year due to inefficient reverse logistics processes.

Key Components of Green Logistics

Green logistics consists of several interconnected components that work together to reduce environmental impact throughout the supply chain. Each element contributes to the overall sustainability of logistics operations and plays a crucial role in minimizing carbon footprints while maintaining operational efficiency.

Sustainable Transportation Methods

Sustainable transportation forms the backbone of green logistics by addressing the largest source of emissions in the supply chain. Companies are implementing multi-modal transport solutions combining rail, sea, and road to optimize fuel efficiency and reduce carbon emissions. Electric and hybrid vehicles have become increasingly prevalent for last-mile deliveries, with major logistics providers like DHL deploying over 10,000 electric delivery vans globally. Route optimization software reduces unnecessary mileage by 15-20%, while shared transportation networks allow businesses to consolidate shipments, increasing vehicle utilization rates from an average of 60% to over 85% capacity.

Eco-Friendly Packaging Solutions

Eco-friendly packaging reduces waste and lowers transportation emissions through lighter, more efficient designs. Biodegradable materials like mushroom packaging, cornstarch-based peanuts, and seaweed-based wrappers replace traditional petroleum-based options with minimal environmental impact. Right-sizing technology creates custom packaging that fits products precisely, reducing material use by up to 40% and increasing shipping density by 20-30%. Reusable packaging systems, including standardized plastic containers and fabric wraps, can be cycled through the supply chain 50-100 times before replacement, dramatically decreasing single-use waste. Companies like P&G have reduced packaging weight by 27% while maintaining product protection, saving millions in shipping costs annually.

Energy-Efficient Warehousing

Energy-efficient warehouses incorporate smart design elements and technologies to minimize resource consumption. LED lighting systems reduce electricity usage by 50-70% compared to traditional lighting, while motion sensors further cut energy use by 30% in low-traffic areas. Automated storage and retrieval systems (AS/RS) optimize space utilization, allowing warehouses to store 30-50% more inventory in the same footprint. Solar panels and wind turbines now power numerous distribution centers, with companies like Amazon installing solar systems capable of generating 80% of a facility's energy needs. Smart temperature control systems adjust cooling and heating based on inventory requirements, reducing HVAC energy consumption by 25-40% while maintaining appropriate conditions for different product types.

Technology Driving Green Logistics

Technological innovation forms the backbone of modern green logistics, enabling companies to reduce their environmental footprint while improving operational efficiency. Advanced technologies are transforming how goods move through supply chains, offering sustainable alternatives to traditional logistics practices.

IoT and Smart Logistics Systems

Internet of Things (IoT) technology revolutionizes logistics operations by connecting physical objects to digital networks for real-time monitoring and optimization. Smart sensors track shipments, monitor vehicle performance, and collect environmental data across supply chains, reducing waste and emissions by up to 20%. Companies like DHL use IoT-enabled warehouses that automatically adjust lighting and temperature based on occupancy, cutting energy consumption by 40%. IoT systems optimize routes by analyzing traffic patterns, weather conditions, and delivery windows, resulting in fewer miles driven and lower fuel consumption. Additionally, predictive maintenance capabilities prevent breakdowns and ensure vehicles operate at peak efficiency, extending equipment lifespan and reducing resource consumption.

Electric and Alternative Fuel Vehicles

Electric vehicles (EVs) represent a critical advancement in sustainable logistics, producing zero tailpipe emissions and reducing operating costs by 20-30% compared to conventional vehicles. Major logistics providers like UPS, FedEx, and Amazon have committed to electrifying significant portions of their fleets, with Amazon ordering 100,000 electric delivery vans from Rivian. Hydrogen fuel cell technology offers another promising alternative, particularly for heavy-duty transport, providing longer ranges and faster refueling times than battery-electric solutions. Companies like Hyundai are deploying hydrogen-powered trucks in commercial operations, with their XCIENT Fuel Cell trucks capable of traveling 400km on a single charge. Biodiesel and renewable natural gas serve as transitional fuels for existing fleets, offering carbon emission reductions of 50-80% compared to conventional diesel without requiring entirely new vehicles.

Business Benefits of Sustainable Logistics Practices

Sustainable logistics practices offer significant business advantages beyond environmental protection. Companies implementing green logistics strategies experience tangible financial returns, improved market positioning, and enhanced operational resilience that directly impact bottom-line performance.

Cost Reduction Opportunities

Sustainable logistics practices create substantial cost savings across multiple operational areas. Optimizing transportation routes reduces fuel consumption by 10-30%, directly lowering shipping expenses. DHL reported annual savings of $185 million through their GoGreen program by implementing more efficient routing algorithms and vehicle utilization techniques. Energy-efficient warehouses equipped with LED lighting, motion sensors, and improved insulation cut facility operational costs by 20-50%, as demonstrated by Unilever's eco-efficient distribution centers.

Waste reduction initiatives like reusable packaging systems and recycling programs minimize disposal costs and create potential revenue streams from recyclable materials. Companies like P&G have saved over $2 billion through their zero-waste-to-landfill initiatives. Additionally, sustainable logistics practices reduce regulatory compliance costs by proactively meeting environmental standards, avoiding potential fines, carbon taxes, and future retrofitting expenses.

Enhanced Brand Reputation

Sustainable logistics practices significantly boost brand reputation and customer loyalty in today's environmentally conscious marketplace. 78% of consumers consider a company's environmental commitments when making purchasing decisions, according to Nielsen's global sustainability report. Brands like Patagonia and IKEA have built strong customer followings by transparently communicating their sustainable supply chain initiatives.

Improved sustainability credentials open access to new market segments, particularly among millennial and Gen Z consumers who prioritize eco-friendly brands. Companies with recognized green logistics programs frequently receive positive media coverage, industry awards, and sustainability certifications that differentiate them from competitors. Organizations like Walmart have strengthened relationships with B2B customers and corporate partners by implementing collaborative sustainability initiatives throughout their logistics networks, creating valuable business partnerships based on shared environmental values.

Regulatory Landscape and Compliance

The regulatory environment for green logistics continues to evolve rapidly, creating both challenges and opportunities for businesses worldwide. Government policies at local, national, and international levels increasingly target supply chain sustainability, requiring companies to adapt their logistics operations to meet stringent environmental standards.

The European Union leads global regulatory efforts with its Green Deal initiative, which aims to achieve carbon neutrality by 2050. The EU Emissions Trading System (ETS) has expanded to include shipping, while the Carbon Border Adjustment Mechanism (CBAM) introduces carbon pricing on imports of carbon-intensive products. These regulations directly impact logistics operations, with non-compliance resulting in significant financial penalties—typically ranging from €50,000 to €100,000 for serious violations.

In North America, the regulatory approach varies by jurisdiction. The U.S. Environmental Protection Agency's SmartWay program encourages voluntary freight efficiency improvements, while California's Advanced Clean Fleets regulation mandates the transition to zero-emission vehicles with specific timelines for different fleet categories. Canada has implemented a federal carbon pricing system that affects fuel costs for logistics operations, adding approximately $0.11 per liter to diesel prices in 2023.

Asian markets demonstrate diverse regulatory frameworks. China's 14th Five-Year Plan includes specific targets for logistics-related emissions reduction, requiring a 18% decrease in carbon intensity by 2025. Japan has established green logistics partnership programs that offer tax incentives for companies adopting sustainable practices, potentially reducing corporate tax burdens by up to 5% for qualifying initiatives.

International shipping faces particularly strict regulatory changes through the International Maritime Organization's (IMO) new standards. The IMO 2020 sulfur cap limited sulfur content in marine fuels to 0.5% (down from 3.5%), while the Carbon Intensity Indicator (CII) and Energy Efficiency Existing Ship Index (EEXI) now grade vessels on emissions performance. Ships receiving poor ratings for three consecutive years must implement corrective action plans or face operational restrictions.

Forward-thinking companies aren't merely complying with current regulations but preparing for future requirements. This proactive approach includes comprehensive emissions tracking systems, supply chain carbon footprint analysis tools, and regular sustainability audits. Companies like Unilever and Nestlé have implemented advanced compliance management systems that track regulatory changes across 100+ markets and automatically flag potential compliance issues within their logistics networks.

The regulatory landscape for green logistics will continue to tighten as governments pursue ambitious climate goals. Businesses that establish robust compliance frameworks today position themselves for competitive advantage in tomorrow's more regulated marketplace, avoiding disruptions and capturing opportunities that arise from regulatory shifts.

Case Studies: Leading Companies in Green Logistics

DHL Group's GoGreen Program

DHL Group stands at the forefront of sustainable logistics with its comprehensive GoGreen program. This initiative targets a 50% reduction in logistics-related emissions by 2025 compared to 2007 levels. DHL has already achieved a 35% improvement in carbon efficiency through strategic changes to its operations. The company deployed over 15,000 electric vehicles across its global delivery network and installed more than 20,000 charging points at its facilities. Their Leipzig hub operates with 100% renewable energy, featuring a 27,000 square meter solar array that generates 2 million kWh annually. DHL's alternative fuel strategy includes using sustainable aviation fuel for air freight, cutting emissions by up to 80% compared to conventional jet fuel.

IKEA's Sustainable Transport Revolution

IKEA transformed its logistics operations with an ambitious goal to reduce transport emissions by 70% by 2030. The company redesigned its iconic flat-pack products to optimize shipping space, resulting in 40% fewer trucks needed for the same volume of products. In urban centers across Europe, IKEA implemented electric vehicle deliveries covering the "last mile" to customers' homes. Their innovative logistics centers incorporate renewable energy systems, with 19 distribution facilities operating at net-zero energy consumption. IKEA's partnership with shipping companies to use biofuel-powered vessels reduced maritime emissions by 85% on key shipping routes, demonstrating how product design and logistics can work together to dramatically lower environmental impact.

Unilever's Zero-Waste Supply Chain

Unilever implemented a zero-waste supply chain model that eliminated landfill waste from its global network of 600 sites. Their Sustainable Living Plan resulted in absolute waste reduction of 96,000 tonnes annually across distribution operations. The company's logistics transformation includes multi-modal shipping solutions that combine rail, road, and sea transport to reduce carbon emissions by 38% since 2010. Unilever's temperature-controlled warehouses use advanced insulation and natural refrigerants, cutting energy consumption by 30%. Their supplier collaboration program extends sustainability requirements to 56,000 partners, creating ripple effects throughout the industry. The company's commitment to returnable packaging systems reduced packaging waste by 27%, creating a model for circular logistics systems.

Maersk's Carbon-Neutral Shipping Initiative

Maersk revolutionized maritime shipping with its commitment to carbon neutrality by 2050. The company invested $1.4 billion in developing methanol-powered container vessels, with the first carbon-neutral ship launched in 2023. Their fleet optimization algorithms reduced vessel fuel consumption by 15% across 700 ships worldwide. Maersk's port operations transformation includes electrified equipment at 17 major terminals, cutting emissions by 70% compared to diesel-powered alternatives. Their collaboration with customers through the Maersk ECO Delivery program allowed companies to choose carbon-neutral transport options, experiencing 200% growth in adoption since its launch. These initiatives demonstrate how even the most carbon-intensive logistics sectors can implement meaningful sustainability transformations.

Walmart's Project Gigaton

Walmart's Project Gigaton represents one of the most ambitious supplier engagement programs for sustainable logistics. This initiative aims to reduce one billion metric tons of greenhouse gases from Walmart's global value chain by 2030. The company optimized its transportation network, achieving 87% efficiency improvement in trailer utilization and eliminating 1.2 billion empty miles annually. Walmart converted 93% of its distribution centers to LED lighting, reducing energy consumption by 40%. Their packaging optimization program eliminated 213 million pounds of plastic packaging and saved 86 million trees through sustainable sourcing. Walmart's supplier scorecard system tracks and rewards partners' sustainability performance, creating competitive pressure that drives industry-wide improvements in logistics practices.

Challenges in Implementing Sustainable Logistics Solutions

Despite the clear benefits of green logistics, companies face significant obstacles when transitioning to more sustainable practices. These challenges span financial, operational, and organizational dimensions that can impede even the most committed sustainability initiatives.

Financial Barriers

The financial obstacles to implementing green logistics solutions often deter companies from making necessary changes. Initial investments in sustainable technologies typically require substantial capital expenditure. Electric delivery vehicles cost 40-50% more upfront than conventional vehicles, though they offer lower lifetime operating costs. Similarly, retrofitting warehouses with energy-efficient systems demands investments of $2-5 per square foot, creating budget pressures for logistics managers working with tight margins.

Return on investment timelines for green initiatives frequently extend beyond traditional corporate planning cycles. Solar panel installations for distribution centers, for example, may take 5-7 years to reach payback despite their 25+ year operational lifespan. This ROI gap creates difficult decisions for financial decision-makers balancing short-term profitability with long-term sustainability goals.

Technological Integration Issues

Technological challenges create significant friction when implementing sustainable logistics systems. Legacy supply chain management software often lacks compatibility with newer sustainability tracking tools, creating data silos and reporting inconsistencies. Companies like Target and Costco have reported spending 15-20% of their sustainability budgets on systems integration alone.

Infrastructure limitations further complicate technology adoption. Electric vehicle deployment faces constraints from inadequate charging networks, particularly in rural distribution routes. Alternative fuel vehicles encounter similar challenges with limited fueling stations, restricting their operational range and effectiveness for long-haul transport.

Operational Complexity

The operational complexity of sustainable logistics creates implementation hurdles across the supply chain. Redesigning logistics networks to optimize for carbon reduction rather than just cost and speed requires sophisticated modeling capabilities many organizations lack. Multi-modal transportation options that reduce emissions often introduce additional transfer points and coordination requirements.

Global supply chains magnify these complexities exponentially. Varying environmental standards across countries create compliance challenges, while differences in sustainability infrastructure between regions complicate standardized approaches. Companies operating across 20+ countries report spending 30-40% more time on sustainability compliance than on single-country operations.

Stakeholder Alignment

Achieving stakeholder alignment represents a critical challenge for sustainable logistics initiatives. Internal resistance often emerges from departments with competing priorities – procurement teams focused on cost savings may resist higher-priced sustainable suppliers, while operations teams measured on delivery times may object to lower-carbon transportation methods with longer transit times.

External stakeholder coordination proves equally challenging. Sustainable logistics requires collaboration across supply chain partners with different capabilities and commitment levels. Suppliers in developing regions may lack resources to meet heightened sustainability requirements, creating potential supply disruptions when implementing stricter standards.

Measurement and Reporting Obstacles

Effective measurement and reporting of sustainability impacts remains problematic for many organizations. Inconsistent methodologies for calculating carbon footprints create confusion and comparison difficulties. The Greenhouse Gas Protocol offers standardized approaches, but companies interpret and implement these guidelines differently, leading to reporting variations of 15-25% for similar activities.

Data collection gaps further undermine measurement efforts. Scope 3 emissions (occurring in the value chain but outside direct operations) represent 70-80% of logistics emissions for most companies but are notoriously difficult to track accurately. Third-party logistics providers often supply incomplete or inconsistent environmental data, complicating comprehensive sustainability reporting.

Future Trends in Green Logistics and Sustainability

Digital Transformation and Smart Supply Chains

Digital transformation is revolutionizing green logistics through interconnected smart systems. AI-powered predictive analytics now optimize routes in real-time, reducing fuel consumption by 15-30% while minimizing empty miles. Blockchain technology enhances supply chain transparency, allowing companies to verify sustainability claims and track carbon footprints across multiple tiers of suppliers. Digital twins—virtual replicas of physical supply chains—enable companies to simulate changes before implementation, identifying potential efficiency gains and environmental impacts. Companies like IBM and Maersk have implemented TradeLens, a blockchain-based platform that digitizes shipping documentation, eliminating millions of paper documents annually and streamlining operations.

Circular Economy Integration

The circular economy model is transforming logistics networks from linear to regenerative systems. Reverse logistics capabilities are expanding beyond simple returns to include comprehensive product lifecycle management, with companies like H&M collecting over 100,000 tons of textiles annually for recycling or resale. Collaborative consumption platforms facilitate asset sharing, increasing utilization rates of vehicles and warehouse space by up to 40%. Modular product design is enabling easier disassembly and remanufacturing, with companies like Philips designing lighting systems as services rather than disposable products. This shift requires logistics providers to develop specialized capabilities for product recovery, refurbishment, and materials reclamation.

Renewable Energy Adoption

Renewable energy is becoming central to sustainable logistics operations. Solar-powered warehouses and distribution centers reduce operational emissions by 60-90%, with companies like Amazon installing 50+ MW of rooftop solar capacity across their fulfillment network. Microgrids provide resilience while incorporating renewable sources, protecting operations from grid disruptions while reducing carbon footprints. Green hydrogen is emerging as a promising solution for heavy-duty transport, with companies like Nikola developing hydrogen-powered trucks capable of 500+ mile ranges. These energy transitions require significant infrastructure investments but offer long-term cost stability and emissions reductions that align with science-based climate targets.

Urban Logistics Reinvention

Urban logistics is undergoing dramatic transformation to address congestion and pollution challenges. Micro-fulfillment centers positioned within city limits reduce last-mile delivery distances by 30-50%, while electric cargo bikes can complete deliveries 60% faster than vans in congested areas. Drone deliveries are becoming commercially viable for certain applications, with companies like Wing completing over 100,000 commercial drone deliveries with minimal environmental impact. Multi-carrier parcel lockers are reducing failed deliveries and consolidating drop-offs, with systems like DHL Packstations handling millions of packages annually. These innovations help reduce urban pollution while maintaining delivery speed that consumers demand.

Alternative Fuels and Propulsion Technologies

Transportation is embracing diverse alternative fuels beyond battery-electric solutions. Sustainable aviation fuel (SAF) reduces aircraft emissions by 80% compared to conventional jet fuel, with companies like DHL committing to 30% SAF usage by 2030. Hydrogen fuel cell technology shows particular promise for long-haul transport, offering quick refueling and extended range capabilities. Biomethane produced from organic waste provides a circular solution for heavy goods vehicles, with carbon-negative potential when capturing emissions from agricultural waste. Advanced battery chemistries are extending electric vehicle ranges while reducing dependence on rare earth minerals, with solid-state batteries potentially doubling energy density compared to current lithium-ion technologies.

Autonomous Logistics Systems

Autonomous technologies are set to transform logistics operations through enhanced efficiency and reduced emissions. Self-driving trucks can improve fuel efficiency by 10-15% through optimal acceleration and braking patterns while reducing accident rates. Autonomous mobile robots (AMRs) in warehouses reduce energy consumption by operating in reduced-light conditions and optimizing movement patterns. Autonomous ships equipped with AI navigation systems can reduce fuel consumption by up to 20% through optimized routing and operational efficiency. These systems reduce human error while maximizing resource utilization, creating both environmental and economic benefits for logistics operators willing to invest in these emerging technologies.

Key Takeaways

- Green logistics integrates environmental considerations into supply chain management, balancing operational efficiency with ecological responsibility through transport optimization, sustainable warehousing, and improved packaging.

- Traditional logistics contributes significantly to environmental degradation, with transportation activities accounting for 24% of global CO2 emissions and generating substantial packaging waste that often ends up in landfills.

- Implementing sustainable logistics practices offers concrete business benefits including cost reductions of 10-30% in fuel consumption, enhanced brand reputation among environmentally conscious consumers, and improved regulatory compliance.

- Leading companies like DHL, IKEA, and Unilever demonstrate the feasibility of green logistics through electric vehicle deployment, redesigned packaging, renewable energy usage, and zero-waste supply chain models.

- Future trends in sustainable logistics include AI-powered route optimization, blockchain-based supply chain transparency, circular economy integration, and alternative fuel technologies that promise to further reduce environmental impacts.

Conclusion

Green logistics is no longer just an environmental choice but a strategic business imperative. As you've seen throughout this article the integration of sustainable practices into your supply chain offers multiple benefits beyond ecological protection.

By embracing technologies like IoT electric vehicles and AI-powered analytics you'll position your business for future regulatory compliance while reducing operational costs. Companies that lead in this space aren't just saving the planet—they're gaining competitive advantage.

The path to sustainable logistics may present challenges but the potential rewards are substantial: enhanced brand reputation stronger customer loyalty and improved operational efficiency.

The future of logistics is undeniably green. Those who adapt now will thrive in an increasingly sustainability-focused marketplace where environmental responsibility and business success go hand in hand.