Key Takeaways

- Building strong relationships (guanxi) with Chinese suppliers requires understanding cultural concepts like "face" (mianzi), personal meetings, and respecting hierarchies to establish trust and preferential treatment

- Overcome language barriers by using simple language, visual aids, bilingual documents, and platforms like WeChat while establishing regular communication schedules with designated contacts

- Implement comprehensive quality control through detailed specifications, multi-stage inspections (pre-production, during production, and pre-shipment), and standardized testing methods like AQL sampling

- Develop contracts in both English and Chinese with key clauses covering payment terms, quality standards, intellectual property protection, and dispute resolution mechanisms that align with Chinese legal requirements

- Plan manufacturing schedules around Chinese holidays (especially Chinese New Year) by adding 30-50% time buffers, implementing milestone checkpoints, and developing contingency plans for inevitable delays

- Negotiate payment terms strategically, starting with 30/70 splits and working toward milestone payments while protecting against currency fluctuations through forward contracts or dual-currency agreements

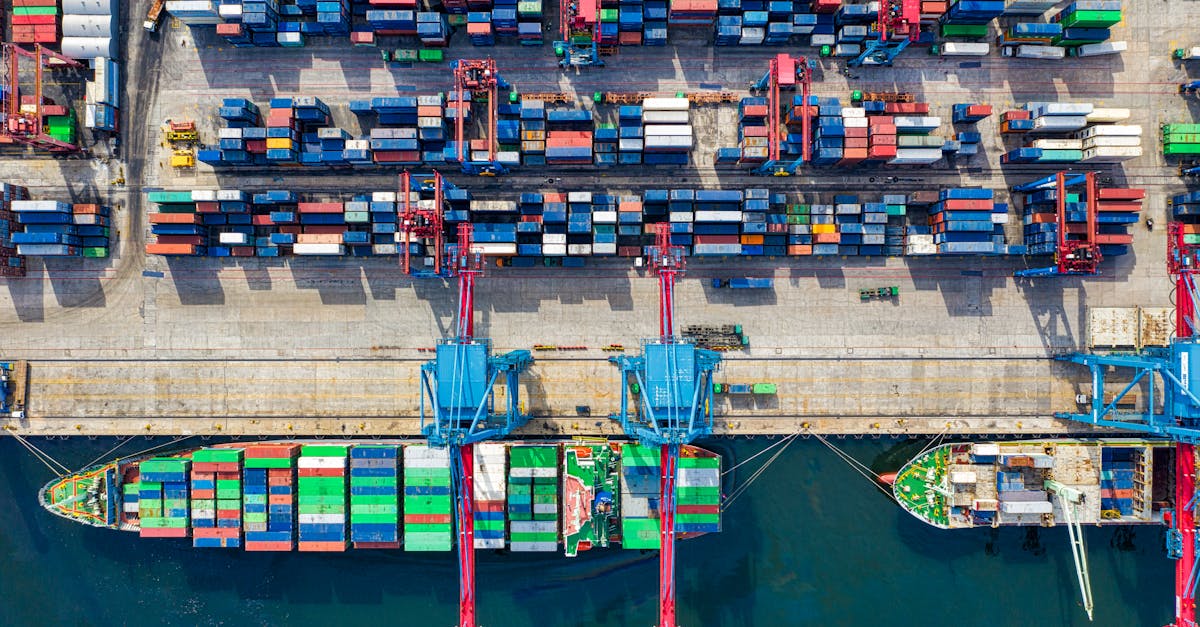

Working with Chinese suppliers can transform your business, offering competitive prices and vast manufacturing capabilities. Yet managing these relationships across cultural differences, time zones, and language barriers requires specific strategies to ensure success.

You'll need more than basic sourcing knowledge to effectively navigate the Chinese manufacturing landscape. From establishing clear communication channels to understanding cultural business practices, the right approach can help you build profitable long-term partnerships while avoiding common pitfalls that plague many importers.

In this guide, we'll explore proven techniques for managing Chinese suppliers that balance quality control, cost efficiency, and sustainable business relationships—essential skills in today's global marketplace.

Understanding Chinese Business Culture

Chinese business culture is built on traditions and social norms that differ significantly from Western practices. Getting acquainted with these cultural nuances creates stronger business relationships and helps avoid misunderstandings when working with Chinese suppliers.

The Importance of Guanxi

Guanxi refers to the personal connections and relationships that form the foundation of Chinese business interactions. This network-based approach emphasizes long-term relationships built on trust and mutual benefit rather than simply transactional exchanges. Building guanxi with your Chinese suppliers involves:

- Personal meetings: Traveling to China to meet suppliers face-to-face demonstrates commitment and helps establish personal connections.

- Gift exchanges: Appropriate business gifts show respect and goodwill, though they shouldn't be overly expensive or appear as bribes.

- Shared meals: Business dinners and lunches provide informal settings to strengthen relationships outside formal negotiations.

- Patience in communications: Taking time to engage in personal conversations before discussing business matters shows respect for relationship-building.

Companies with strong guanxi networks gain access to better terms, faster problem resolution, and preferential treatment during supply shortages or production delays.

Face Concept in Chinese Business Relationships

"Face" (mianzi) represents social status, reputation, and dignity in Chinese culture. Understanding this concept is crucial when managing Chinese suppliers because maintaining face influences decision-making and communication styles. Key aspects include:

- Avoiding public criticism: Critiquing suppliers in front of others causes them to lose face, potentially damaging your relationship permanently.

- Indirect communication: Chinese partners often use subtle language and non-verbal cues rather than direct confrontation when problems arise.

- Respecting hierarchy: Addressing the appropriate decision-makers shows respect for organizational structure and helps preserve face.

- Providing praise: Recognizing achievements and expressing gratitude publicly helps suppliers gain face among their peers and superiors.

When quality issues occur, discussing them privately with the appropriate manager preserves face while still addressing the problem. Similarly, granting reasonable deadline extensions when possible helps suppliers maintain face rather than forcing them to admit they can't meet original timelines.

Effective Communication Strategies

Effective communication forms the foundation of successful supplier relationships in China. Clear, consistent, and culturally appropriate communication helps prevent misunderstandings and builds stronger business partnerships across borders.

Overcoming Language Barriers

Language differences present significant challenges when working with Chinese suppliers. English proficiency varies widely among Chinese manufacturing personnel, with production staff typically having less English capability than sales representatives. To overcome these barriers:

- Use simple language: Avoid idioms, complex sentences, and industry jargon that may not translate well.

- Provide visual aids: Include product drawings, photos, and video demonstrations to clarify specifications and requirements.

- Confirm understanding: Ask suppliers to repeat instructions back to you in their own words to verify comprehension.

- Create bilingual documents: Develop key specifications and contracts in both English and Chinese to minimize misinterpretations.

- Employ a translator: Hire professional translation services for critical communications, especially for complex technical specifications or legal documents.

Many successful importers establish a standardized communication template that includes both languages and visual references for recurring orders, reducing the potential for errors caused by language misunderstandings.

Using the Right Communication Channels

Selecting appropriate communication channels significantly impacts the effectiveness of your supplier interactions. Chinese business professionals utilize different platforms than their Western counterparts:

- WeChat: This serves as the primary business communication tool in China, combining messaging, voice calls, and file sharing capabilities.

- Email: While useful for formal documentation and record-keeping, emails receive slower responses than instant messaging platforms.

- Video conferences: Platforms like Zoom or WeChat video calls help build rapport and clarify complex issues that text-based communication can't adequately address.

- On-site visits: Face-to-face meetings remain invaluable for establishing trust and resolving significant issues.

- Alibaba messaging: For suppliers found through Alibaba, their native messaging system offers integrated translation features.

Communication frequency also matters—regular check-ins during production cycles help identify potential issues early. Establishing a communication schedule with designated points of contact on both sides creates accountability and ensures information flows smoothly throughout the manufacturing process.

Quality Control Measures

Quality control measures safeguard your product standards when working with Chinese suppliers. These processes help prevent defects, reduce waste, and ensure customer satisfaction.

Setting Clear Specifications

Clear product specifications form the foundation of effective quality control with Chinese suppliers. Document every aspect of your product requirements, including materials, dimensions, colors, functionality, packaging, and performance standards. Create detailed technical drawings with precise measurements, tolerances, and critical-to-quality characteristics.

Develop a comprehensive quality control checklist that outlines acceptance criteria and testing methods for each specification. Share reference samples that demonstrate the expected quality standard, which provide tangible examples for suppliers to follow. Use standardized terminology and include Chinese translations to minimize misinterpretations.

Organize specification reviews with your supplier to address questions and confirm understanding before production begins. Update your specifications document whenever changes occur and maintain version control to ensure everyone works from the current requirements.

Implementing Regular Inspections

Regular inspections throughout the production process catch quality issues before they escalate. Implement a multi-stage inspection system that includes pre-production, during production, and pre-shipment checks. During pre-production inspections, verify raw materials meet specifications and approve initial samples before mass production begins.

Schedule random in-process inspections to monitor production quality at various stages. These checks identify deviations from specifications early, allowing for timely corrections. Pre-shipment inspections evaluate finished products against your quality standards, examining functionality, appearance, packaging, and quantity.

Use standardized inspection methods like AQL (Acceptable Quality Limit) sampling to determine how many units to inspect and what defect levels are acceptable. Document inspection results with photos and detailed reports to track supplier performance over time. Consider hiring third-party inspection services with local expertise and no conflicts of interest for more objective assessments.

Establish clear procedures for handling failed inspections, including corrective action requirements and re-inspection protocols. Train your Chinese suppliers on your quality expectations and involve them in developing solutions when issues arise.

Contract Management

Effective contract management forms the foundation of successful relationships with Chinese suppliers. A well-drafted contract protects your interests, sets clear expectations, and provides legal recourse if disputes arise.

Key Clauses to Include

Strong contracts with Chinese suppliers include several essential clauses that safeguard your business interests. Payment terms should specify currency, payment methods, and timing, typically structured as 30% deposit and 70% before shipment. Quality standards must detail acceptable defect rates, reference samples, and testing methods with measurable parameters. Intellectual property protection clauses explicitly state ownership rights and confidentiality obligations to prevent unauthorized use of your designs. Include specific delivery terms following Incoterms 2020 standards that clarify shipping responsibilities, insurance coverage, and risk transfer points. Dispute resolution mechanisms should establish jurisdiction preferences (Hong Kong or Singapore often serve as neutral venues) and set mediation procedures before escalating to arbitration.

Navigating Chinese Contract Law

Chinese contract law differs significantly from Western legal frameworks, requiring specific approaches for enforcement. Contracts must be written in both English and Chinese, with the Chinese version typically prevailing in legal disputes. Using a company's official chop (stamp) rather than just signatures provides greater legal protection, as Chinese courts recognize these seals as binding authorization. Register your intellectual property directly with Chinese authorities through trademarks and patents for maximum protection, as contracts alone may provide insufficient safeguards. Chinese courts generally favor specific performance remedies (completing contractual obligations) over monetary damages when resolving disputes. Working with legal experts who specialize in Chinese business law helps navigate these complexities and ensures your contracts align with local legal requirements while maintaining your business objectives.

Building Long-Term Supplier Relationships

Long-term relationships with Chinese suppliers create stability and mutual growth in your supply chain. These partnerships go beyond transactional exchanges to foster collaboration, innovation, and preferential treatment that benefits both parties.

Balancing Price Negotiations with Partnership

Effective price negotiations with Chinese suppliers require balancing cost concerns with relationship building. Focus on creating win-win scenarios rather than squeezing every penny from each transaction. Present cost reduction as a mutual goal—when your business grows, their business grows too. Share your market challenges transparently to help suppliers understand your pricing constraints.

Set clear expectations about gradual price improvements tied to order volume increases. Many Chinese suppliers offer tiered pricing structures that reward loyalty with better rates on larger or repeated orders. Avoid aggressive negotiation tactics that might damage your guanxi (relationship network), as Chinese business culture values long-term partnerships over short-term gains.

Consider implementing cost-saving collaborations such as joint material sourcing, simplified packaging, or production process improvements. These approaches demonstrate your commitment to the relationship while achieving cost objectives. Several successful importers maintain spreadsheets tracking cost-reduction initiatives with their Chinese partners, reviewing progress quarterly.

In-Person Visits and Their Impact

Face-to-face meetings dramatically strengthen relationships with Chinese suppliers in ways digital communication cannot match. Regular visits to supplier facilities demonstrate serious commitment and build trust essential for preferential treatment during busy production seasons or material shortages. The typical recommendation is visiting key suppliers 2-3 times annually, with at least one visit coinciding with a major Chinese business event or trade show.

During facility visits, spend time with both management and production staff to understand their capabilities and challenges firsthand. Ask to see current production processes, quality control procedures, and material storage areas. Many suppliers showcase innovations or new equipment during these tours that might benefit your products.

Cultural engagement during visits significantly impacts relationship building. Share meals with supplier representatives, exchange appropriate gifts (company-branded items work well), and participate in activities outside the factory setting. These social interactions create personal connections that translate into business advantages, including faster problem resolution and greater supplier flexibility.

After visits, document observations, agreements, and action items in writing, sharing them with both your team and the supplier. This practice reinforces commitments made during in-person meetings and provides a reference point for future discussions. Companies that maintain consistent visit schedules report 40-60% fewer quality issues and more favorable payment terms compared to those relying solely on remote communication.

Managing Lead Times and Production Schedules

Effective management of lead times and production schedules is crucial when working with Chinese suppliers. Chinese manufacturing timelines often differ from Western expectations, requiring strategic planning and proactive management to maintain smooth operations.

Planning for Chinese Holidays

Chinese holidays significantly impact production schedules and require advance planning to avoid disruptions. The Chinese New Year (Spring Festival) causes nationwide factory closures for 2-4 weeks between January and February, creating a manufacturing standstill. Other major holidays like National Day (October 1-7) and Mid-Autumn Festival also affect production capacity. To manage these holiday periods effectively:

- Schedule orders 3-4 months in advance of major holidays to ensure completion before shutdowns

- Adjust inventory levels by stocking additional products before extended holidays

- Create a comprehensive Chinese holiday calendar and integrate it into your annual planning cycle

- Communicate early with suppliers about your needs during holiday seasons

- Place orders earlier during pre-holiday periods when many companies rush to complete production

Remember that many factory workers travel home during major holidays, and operations often slow down in the weeks before and after as workers depart early or return late.

Buffer Strategies for Delays

Implementing buffer strategies helps mitigate common delays when working with Chinese suppliers. Production delays stem from various factors including material shortages, power restrictions, equipment breakdowns, and quality issues. To protect your supply chain:

- Add a 30-50% time buffer to quoted production timelines for realistic scheduling

- Implement a phased ordering system with staggered delivery dates to maintain inventory flow

- Establish milestones and checkpoints throughout the production process to identify delays early

- Diversify your supplier base across different regions of China to reduce geographic risk factors

- Develop contingency plans for critical components, including backup suppliers or alternative materials

- Use air freight selectively for urgent shipments when delays threaten important deadlines

Regular communication with suppliers about production status helps identify potential delays before they become critical. Request weekly progress reports with photos or videos of production to verify actual manufacturing status rather than relying solely on verbal updates.

Handling Payment and Financial Considerations

Managing financial transactions with Chinese suppliers requires careful planning and strategic negotiation. Establishing clear payment terms and understanding currency risks are crucial components of successful supplier relationships in China.

Negotiating Favorable Payment Terms

Payment terms significantly impact your cash flow and risk exposure when working with Chinese suppliers. Most Chinese manufacturers initially request 100% payment upfront, especially with new clients, but this arrangement places all financial risk on you. Start by proposing a 30/70 split—30% deposit and 70% upon completion—and gradually work toward better terms as trust develops. For larger orders exceeding $20,000, negotiate milestone payments tied to production stages, such as 30% deposit, 40% after pre-shipment inspection, and 30% upon delivery.

Use T/T (Telegraphic Transfer) for smaller orders and established relationships, while Letter of Credit (L/C) provides more security for larger transactions by involving bank verification. Escrow services like Alibaba Trade Assurance offer a middle ground, holding funds until delivery conditions are met. Always link payment releases to quality benchmarks and document these conditions in your contract to strengthen your position during negotiations.

Currency Fluctuation Risks

Currency fluctuations between the USD, Euro, and Chinese Yuan can significantly impact your profit margins when importing from China. The CNY-USD exchange rate often fluctuates by 3-5% within a quarter, directly affecting your purchasing power. Implement currency risk management strategies such as forward contracts, which lock in exchange rates for future transactions, protecting you from unfavorable market movements.

Consider negotiating dual-currency contracts that specify prices in both USD and CNY with predetermined exchange rate bands. This approach creates clarity and shares currency risk between both parties. For recurring orders, establish a price adjustment formula that triggers when exchange rates move beyond an agreed threshold—typically 3-4%. Working with suppliers who maintain foreign currency accounts reduces conversion costs and simplifies transactions. Banking platforms like TransferWise or OFX offer competitive exchange rates and lower fees compared to traditional banks, saving up to 2-3% on international transfers.

Conclusion

Mastering the management of Chinese suppliers requires understanding both cultural nuances and practical strategies. By developing strong guanxi cultivating face-conscious interactions and implementing robust quality control you'll build sustainable partnerships that benefit your business long-term.

Remember that clear communication contracts tailored to Chinese business practices and strategic financial management form the foundation of successful supplier relationships. Regular in-person visits thoughtful holiday planning and buffer strategies for lead times will further strengthen your supply chain.

The effort you invest in these relationships today will pay dividends through improved quality consistent delivery and competitive pricing. With these strategies you're now equipped to navigate the complexities of Chinese manufacturing and transform potential challenges into opportunities for business growth.

Frequently Asked Questions

What are the main benefits of working with Chinese suppliers?

Chinese suppliers offer competitive pricing and extensive manufacturing capabilities. They can produce a wide range of products at scale, often at lower costs than Western manufacturers. Working with Chinese suppliers gives businesses access to established supply chains and specialized expertise in various industries, potentially increasing profit margins and product offerings.

How important is understanding guanxi in Chinese business culture?

Guanxi (personal connections) is crucial when working with Chinese suppliers. This relationship-based business approach requires building trust through personal meetings, appropriate gift exchanges, shared meals, and patience. Companies that invest in strong guanxi networks typically receive better terms, faster problem resolution, and priority treatment during busy production periods.

What is the concept of "face" in Chinese business relationships?

"Face" refers to social status and reputation in Chinese culture. Preserving face is essential for successful supplier relationships. This means avoiding public criticism, using indirect communication for negative feedback, respecting hierarchy, and providing praise when appropriate. Address quality issues privately and consider reasonable deadline extensions to maintain harmonious relationships.

How can I overcome language barriers with Chinese suppliers?

Overcome language barriers by using simple language without idioms or slang, incorporating visual aids like technical drawings and samples, creating bilingual documents for important communications, and considering professional translators for complex negotiations. Confirm understanding by asking for specific feedback rather than yes/no questions.

What communication channels work best with Chinese suppliers?

WeChat is essential for instant messaging and regular communications. Video conferences help build rapport and clarify complex issues. Email provides documentation of agreements and specifications. On-site visits are invaluable for building trust and understanding manufacturing capabilities. Establish a schedule with designated contacts to ensure smooth information flow.

What quality control measures should I implement?

Implement clear product specifications with detailed technical drawings and a quality control checklist. Conduct regular inspections throughout production using a multi-stage system: pre-production, in-process, and pre-shipment checks. Consider hiring third-party inspection services for objective assessments. Establish clear procedures for failed inspections and train suppliers on quality expectations.

What should be included in contracts with Chinese suppliers?

Include comprehensive payment terms, detailed quality standards and specifications, intellectual property protection clauses, clear delivery terms (using Incoterms), and dispute resolution mechanisms. Ensure contracts are written in both English and Chinese, use official company seals, and register intellectual property with Chinese authorities for legal protection.

How do Chinese holidays affect production schedules?

Chinese holidays, especially Chinese New Year (typically January-February) and Golden Week (October), can significantly impact production schedules. Factories often close for 2-3 weeks during these periods, with productivity affected weeks before and after as workers travel home. Plan orders well in advance, maintain higher inventory, and adjust lead times to accommodate these predictable disruptions.

What payment terms are typical with Chinese suppliers?

Common payment structures include 30% deposit with 70% before shipment for established relationships. New relationships might require 50% upfront or even 100% prepayment. Consider milestone payments for larger orders and escrow services for new partnerships. Use secure payment methods like bank transfers or letters of credit rather than Western Union or PayPal for large transactions.

How can I mitigate currency fluctuation risks?

Mitigate currency risks by negotiating fixed prices for specific time periods, using forward contracts to lock in exchange rates, implementing dual-currency contracts with predetermined conversion rates, and working with banking platforms offering competitive exchange rates. Monitor market trends and adjust pricing strategies accordingly to protect profit margins.