In today's fast-paced business environment, logistics outsourcing has emerged as a strategic solution for companies looking to streamline operations and focus on core competencies. By partnering with third-party logistics providers (3PLs), you're able to leverage specialized expertise without investing in expensive infrastructure or personnel training.

The advantages of logistics outsourcing extend far beyond simple cost savings. When you delegate your supply chain management to experts, you'll gain access to advanced technologies, global networks, and industry best practices that might otherwise be out of reach. From warehouse management to transportation coordination, outsourcing creates opportunities for efficiency and scalability that can transform your business operations.

What Is Logistics Outsourcing?

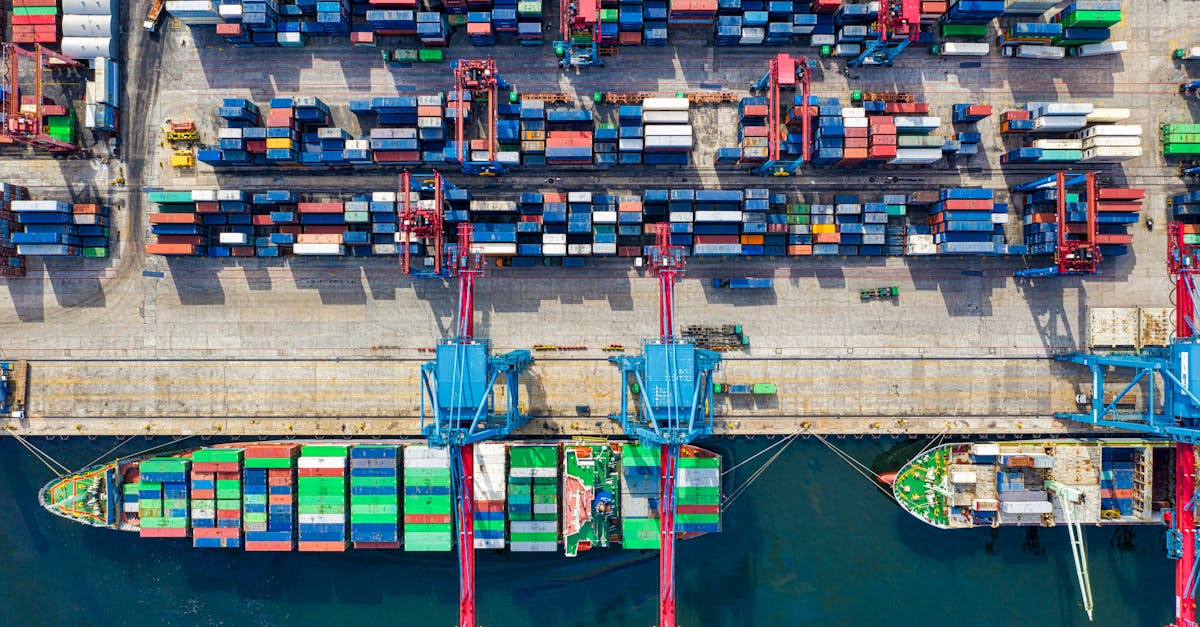

Logistics outsourcing refers to the practice of hiring external logistics service providers to handle part or all of a company's supply chain operations. This strategic business approach involves transferring logistics responsibilities—including transportation, warehousing, inventory management, order fulfillment, and freight forwarding—to specialized third-party logistics (3PL) companies.

When you outsource logistics functions, you're essentially partnering with experts who focus exclusively on supply chain management. These providers offer dedicated resources, specialized knowledge, and established networks that would otherwise require significant investment to develop in-house. For example, 3PL providers like DHL, FedEx, and C.H. Robinson maintain extensive transportation fleets, warehouse facilities, and technology systems specifically designed for efficient logistics operations.

The scope of logistics outsourcing varies widely based on business needs. Some companies outsource specific functions like transportation or warehousing, while others implement comprehensive solutions covering the entire supply chain. This flexibility allows businesses of all sizes to tailor outsourcing arrangements to their particular requirements, operational goals, and budget constraints.

Modern logistics outsourcing extends beyond basic transportation and storage services to include value-added capabilities such as:

- Inventory optimization using advanced forecasting algorithms and real-time tracking

- Cross-docking operations to minimize handling and storage requirements

- Reverse logistics management for returns processing and product reclamation

- Supply chain analytics providing actionable insights on performance metrics

- Customs brokerage to navigate international shipping regulations

The market for logistics outsourcing continues to grow rapidly, with global 3PL revenues reaching $1.1 trillion in 2022, representing an 8.4% increase from the previous year according to Armstrong & Associates research.

Key Advantages of Logistics Outsourcing

Logistics outsourcing delivers significant competitive advantages that extend far beyond operational improvements. Companies partnering with third-party logistics providers unlock multiple benefits that directly impact their bottom line, operational efficiency, and strategic positioning in the marketplace.

Cost Reduction and Financial Benefits

Logistics outsourcing transforms fixed costs into variable expenses, creating immediate financial advantages for your business. By eliminating the need to invest in warehouse facilities, transportation fleets, and specialized equipment, you'll reduce capital expenditures by 15-30% on average. Third-party logistics providers leverage economies of scale across multiple clients, passing savings onto you through lower per-unit handling costs. Their established carrier networks typically secure freight rates 8-12% below what individual companies can negotiate independently. Additional financial benefits include:

- Reduced labor costs from eliminating the need to hire, train, and manage logistics personnel

- Lower inventory carrying costs through improved inventory management and reduced safety stock requirements

- Minimized technology investment by utilizing the 3PL's existing systems rather than purchasing expensive WMS or TMS solutions

- Predictable pricing models with transparent fee structures based on actual usage or activity levels

Access to Specialized Expertise and Technology

Third-party logistics providers offer access to specialized knowledge and advanced technologies that would be prohibitively expensive to develop in-house. These providers employ logistics experts with deep industry experience and stay current with best practices, regulations, and market trends. Their technology stack typically includes:

- Advanced warehouse management systems that optimize picking routes and inventory placement

- Real-time tracking platforms providing end-to-end visibility across your supply chain

- Predictive analytics tools that identify patterns and anticipate potential disruptions

- Automation technologies including robotics and AI-powered systems that increase efficiency

Working with a 3PL grants you immediate access to these capabilities without the development time or integration challenges of building them yourself. Their expertise extends to specialized handling requirements, international shipping regulations, and custom logistics solutions tailored to your specific industry needs.

Improved Focus on Core Business Functions

Outsourcing logistics operations frees up valuable internal resources to concentrate on activities that directly drive revenue and competitive advantage. By transferring logistics responsibilities to specialists, your team can redirect their attention to product development, customer service, marketing initiatives, and strategic planning. This realignment of focus leads to:

- Increased productivity in departments directly tied to revenue generation

- Enhanced innovation capacity with more resources available for R&D and product improvement

- Stronger customer relationships through greater attention to client needs and service quality

- Faster market responsiveness with leadership bandwidth focused on strategic decisions rather than logistics challenges

Companies that outsource logistics functions report spending 40-60% less time managing day-to-day transportation and warehousing issues, creating significant opportunities to strengthen core business operations and strategic initiatives.

Strategic Benefits for Different Business Sizes

Logistics outsourcing delivers tailored advantages across various organizational scales, with benefits that adapt to specific operational requirements. Companies of different sizes experience unique advantages when partnering with third-party logistics providers, creating customized value propositions based on business complexity and growth stage.

Small Business Advantages

Small businesses gain transformative benefits from logistics outsourcing, effectively competing against larger rivals despite limited resources. By partnering with 3PLs, small companies access enterprise-grade logistics infrastructure without capital investments, reducing startup costs by 35-40%. This arrangement converts fixed logistics expenses into variable costs that scale with business volume, preserving cash flow for core growth initiatives such as product development and marketing.

Logistics providers offer small businesses immediate access to established distribution networks spanning multiple regions, enabling market expansion without physical presence investments. Small companies partnering with 3PLs report 25-30% faster order fulfillment times and 15-20% improvement in on-time delivery rates, enhancing customer satisfaction metrics critical for reputation building.

The expertise gap represents another significant challenge addressed through outsourcing, as small businesses typically lack specialized logistics personnel. 3PLs provide instant access to experienced professionals, eliminating recruitment and training costs while ensuring compliance with complex shipping regulations, customs requirements, and industry best practices.

Enterprise-Level Benefits

Large enterprises leverage logistics outsourcing to enhance operational agility and achieve strategic transformation across complex supply chains. For multinational corporations, 3PLs integrate fragmented regional logistics networks into cohesive global systems, standardizing processes across 50+ countries while maintaining local market adaptability. This consolidation typically yields 12-18% cost savings through harmonized operations, negotiation leverage, and redundancy elimination.

Enterprise logistics outsourcing enables sophisticated network optimization using advanced modeling techniques and big data analytics. Fortune 500 companies report reducing total logistics costs by 15-22% through network redesign initiatives implemented by specialized 3PL partners, optimizing transportation routes, facility locations, and inventory positioning across multiple tiers of distribution.

Outsourcing also facilitates enterprise digital transformation by bridging technology gaps between legacy systems and cutting-edge logistics innovations. Leading 3PLs deploy comprehensive technology stacks including AI-driven demand forecasting, blockchain for supply chain transparency, and IoT-enabled asset tracking integrated with enterprise ERP systems. This integration provides executives with real-time supply chain visibility across global operations through unified dashboards, supporting data-driven decision making without internal IT overhauls costing millions.

Global Expansion Opportunities Through Outsourced Logistics

Outsourced logistics partners serve as catalysts for international growth, providing the infrastructure and expertise needed to expand into new markets. Companies leveraging 3PL partnerships access established global networks that would take years and significant investment to develop independently.

Navigating International Markets

Logistics outsourcing transforms international expansion from complex to manageable by providing ready-made global distribution channels. Experienced 3PLs maintain physical infrastructure in strategic locations worldwide, including distribution centers in 75+ countries and transportation networks spanning multiple continents. They've cultivated relationships with local carriers, customs officials, and regulatory bodies in diverse markets, reducing your entry barriers by 60-70% compared to establishing operations independently. These partnerships deliver immediate regulatory compliance expertise, with 3PLs managing the complexities of country-specific documentation, labeling requirements, and trade regulations that vary significantly across regions like the EU, Asia-Pacific, and Latin America.

Third-party logistics providers offer localization capabilities essential for market-specific success, including:

- Cultural adaptation of packaging, documentation, and delivery protocols tailored to local preferences

- Regional inventory positioning based on demand patterns, reducing delivery times by 30-50% compared to centralized distribution

- Multi-currency transaction processing and international payment solutions integrated with your existing systems

- Multilingual support services for both your team and customers in target markets

Overcoming Cross-Border Challenges

Cross-border logistics presents numerous obstacles that specialized 3PL providers navigate daily through established processes and technology. customs clearance delays represent one of the most significant barriers to international expansion, with shipments typically facing 2-5 day delays at borders. Outsourced logistics partners reduce these delays by 40-60% through pre-clearance protocols, electronic documentation systems, and relationships with customs authorities in key markets.

Advanced 3PLs excel in several critical areas of international logistics:

- Tariff management and duty optimization, identifying opportunities to reduce import costs by 15-25% through trade agreements and classification expertise

- Compliance assurance across regulatory frameworks, maintaining 98-99% compliance rates compared to 80-85% for companies managing logistics internally

- Supply chain resilience with contingency routing options during disruptions like port congestion or regional conflicts

- International returns handling with localized processing centers cutting cross-border return costs by 30-40%

Companies utilizing outsourced logistics for global expansion report entering new markets 4-6 months faster than competitors managing logistics internally. This acceleration creates first-mover advantages and shortens time-to-revenue in emerging markets where early positioning often determines long-term success.

Measuring ROI from Logistics Outsourcing

Measuring ROI from logistics outsourcing requires a systematic approach that captures both quantitative savings and qualitative improvements. Effective measurement frameworks track both direct cost reductions and broader operational enhancements that impact your bottom line. Companies implementing comprehensive ROI tracking systems typically identify 15-25% more value than those using basic metrics alone.

Key Performance Indicators for Logistics Outsourcing

Logistics outsourcing ROI measurement starts with tracking specific KPIs that reflect operational improvements. Transportation costs per unit shipped decrease by 8-12% on average after logistics outsourcing, while order accuracy rates improve from an industry average of 96% to over 99% with specialized 3PLs. Other essential KPIs include:

- Inventory turnover rates that typically increase 20-30% through improved inventory management

- On-time delivery performance which improves from industry averages of 85-90% to 95-98% with specialized providers

- Order processing times reduced by 30-50% through automation and specialized expertise

- Labor productivity metrics showing 15-25% efficiency gains in warehousing operations

- Return processing costs decreasing 10-15% through streamlined reverse logistics

Cost-Benefit Analysis Frameworks

Cost-benefit analysis for logistics outsourcing compares total outsourcing expenses against the combined value of direct savings and operational improvements. Effective frameworks include transition costs amortized over the contract period, typically representing 5-8% of first-year expenses. A comprehensive cost-benefit analysis includes:

- Direct cost comparisons between in-house operations and outsourced services

- Working capital impacts from reduced inventory requirements, typically freeing 20-30% of previously committed capital

- Risk mitigation values representing avoided costs of disruptions and compliance issues

- Scalability benefits quantified as avoided capital expenditures during growth periods

- Opportunity cost calculations showing financial benefits from reallocating internal resources

Technology-Enabled ROI Tracking

Advanced analytics platforms transform logistics data into actionable ROI insights, allowing continuous performance monitoring. Companies using technology-enabled ROI tracking identify optimization opportunities worth 7-12% in additional savings annually. Modern logistics ROI tracking relies on:

- Supply chain visibility dashboards providing real-time performance metrics

- Predictive analytics tools identifying cost-saving opportunities before implementation

- Automated reporting systems delivering consistent KPI tracking without manual effort

- Benchmark comparison tools measuring performance against industry standards

- Dynamic modeling capabilities for scenario planning and continuous improvement

Long-Term Value Assessment

- Customer satisfaction improvements measured through Net Promoter Scores that typically increase 10-15 points

- Market responsiveness gains quantified by reduced time-to-market for new products

- Business continuity enhancements valued through improved recovery times and reduced disruption costs

- Sustainability benefits measured by reduced carbon footprint and improved ESG metrics

- Competitive positioning advantages reflected in market share gains and customer retention rates

Potential Challenges and How to Overcome Them

Communication and Alignment Issues

Communication gaps create significant roadblocks in logistics outsourcing relationships. When expectations remain unclear or poorly documented, service delivery often falls short of requirements. Companies experience miscommunication with their 3PL partners in 67% of new outsourcing arrangements during the first six months. These misalignments manifest as incorrect shipment prioritization, misunderstood service level agreements, and conflicts over responsibility boundaries.

To overcome these challenges, implement structured communication protocols from day one. Create detailed service level agreements (SLAs) with specific metrics, responsibilities, and escalation procedures. Schedule regular performance reviews—weekly during transition periods and monthly thereafter—to address issues before they escalate. Utilize collaborative platforms like shared dashboards and logistics management software to maintain visibility for all stakeholders. Advanced logistics partnerships also benefit from appointing dedicated relationship managers on both sides who serve as single points of contact for strategic discussions.

Integration and Technology Compatibility

Technology integration obstacles frequently disrupt outsourcing transitions. Legacy systems often struggle to communicate with 3PL platforms, creating data silos that lead to inventory discrepancies, delayed shipments, and poor visibility. Companies report that technical integration challenges extend project timelines by 40-60% and cause data accuracy issues in 52% of new logistics partnerships.

Address these challenges through comprehensive pre-implementation assessments of all systems. Develop detailed integration roadmaps with clearly defined data exchange protocols, API requirements, and backup procedures. Consider implementing middleware solutions specifically designed to bridge enterprise systems with 3PL platforms. Phase implementations strategically, beginning with less critical functions before moving to core operations. For complex integrations, establish joint technical teams with representatives from both your organization and the 3PL to collaborate on solutions.

Loss of Operational Control

Surrendering direct control over logistics operations creates anxiety for many organizations. Decision-makers worry about diminished visibility, reduced ability to make rapid changes, and disconnection from crucial supply chain information. Studies show 71% of companies cite "loss of control" as a primary concern when evaluating logistics outsourcing.

Mitigate control concerns by establishing clear governance frameworks that preserve decision rights while leveraging 3PL expertise. Implement real-time visibility tools that provide continuous monitoring of operational metrics and performance indicators. Develop tiered decision-making protocols that clarify which decisions remain in-house versus those delegated to the 3PL. Start with a hybrid approach that outsources specific functions while maintaining internal control of strategic elements. As the relationship matures, gradually expand the 3PL's responsibilities based on demonstrated performance.

Hidden Costs and Fee Structures

Unexpected costs frequently surface in logistics outsourcing arrangements, eroding anticipated savings. These hidden expenses include accessorial charges, volume fluctuation penalties, system integration costs, and contract modification fees. Companies discover that 23% of outsourcing agreements exceed projected costs by 15% or more in the first year.

Prevent cost surprises by conducting thorough due diligence on pricing models before signing agreements. Request fully transparent fee structures with explicit documentation of all potential charges. Negotiate contracts with clear volume bands that accommodate seasonal fluctuations without triggering penalties. Include detailed change management procedures with associated costs pre-defined. Implement regular financial reviews comparing actual versus projected expenses to identify cost creep early. Consider engaging specialized logistics procurement consultants during contract negotiations to identify potential hidden costs.

Service Quality and Performance Management

Service quality inconsistencies undermine the benefits of logistics outsourcing. Common performance issues include missed delivery windows, inventory discrepancies, improper handling, and poor communication during exceptions. Organizations report that 38% of logistics outsourcing relationships require significant intervention within the first year due to performance shortfalls.

Establish comprehensive performance management systems with clear metrics aligned to business objectives. Develop balanced scorecards covering operational excellence (on-time delivery, accuracy), financial performance (cost per unit), and strategic alignment (continuous improvement initiatives). Implement regular performance reviews with formal escalation procedures for persistent issues. Consider performance-based contracts that link compensation directly to achievement of key metrics. Document and share best practices and standard operating procedures for all critical processes to ensure consistency during staff changes or volume spikes.

Business Continuity and Risk Management

Outsourcing concentrates operational risk with external partners, potentially creating single points of failure in your supply chain. Natural disasters, labor disruptions, or financial instability at a 3PL can severely impact your operations. During the COVID-19 pandemic, companies with single-provider logistics strategies experienced 3.4 times more disruptions than those with diversified approaches.

Develop robust risk management strategies by assessing 3PL business continuity plans during the selection process. Create backup procedures for critical functions and establish relationships with secondary providers for emergency support. Require transparency into your 3PL's subcontractor relationships to understand the full supply chain risk profile. Implement regular risk assessments that evaluate geopolitical, financial, and operational threats to your logistics network. Consider geographic diversification of logistics partners to minimize regional disruption impacts. Establish clear data protection and recovery protocols to ensure business continuity during technological failures.

Key Takeaways

- Logistics outsourcing transforms fixed costs into variable expenses, reducing capital expenditures by 15-30% on average while providing access to specialized expertise and advanced technologies.

- Companies partnering with 3PLs report 40-60% less time spent managing day-to-day logistics operations, allowing them to redirect resources to core business functions like product development and customer service.

- Small businesses gain enterprise-grade logistics infrastructure without capital investments, while large enterprises achieve 12-18% cost savings through network consolidation and standardized global processes.

- Third-party logistics providers accelerate international expansion by 4-6 months compared to in-house logistics management, providing established global networks and expertise in cross-border regulations.

- Effective logistics outsourcing typically improves key performance indicators like order accuracy (to over 99%), on-time delivery (to 95-98%), and inventory turnover rates (by 20-30%).

- Potential challenges include communication gaps, technology integration issues, and loss of operational control, which can be mitigated through structured protocols, comprehensive implementation planning, and transparent governance frameworks.

Conclusion

Partnering with the right logistics provider isn't just a cost-cutting measure—it's a strategic decision that can transform your entire business operations. You'll gain access to specialized expertise global networks and cutting-edge technologies without heavy capital investment.

Whether you're a small business looking to compete with larger enterprises or a multinational corporation streamlining complex supply chains logistics outsourcing offers tailored benefits to match your specific needs.

By converting fixed costs to variable expenses reducing time-to-market and enhancing customer satisfaction you'll position your company for sustainable growth in an increasingly competitive marketplace. The data is clear: companies that strategically outsource logistics functions don't just survive—they thrive.