Key Takeaways

- China dominates global manufacturing with 28.7% of output, offering cost efficiencies of 20-30% compared to Western production across virtually every industry from electronics to textiles.

- Major sourcing platforms include Alibaba (with Trade Assurance protection), Global Sources (premium verification), Made-in-China (virtual factory tours), and industry-specific WeChat networks.

- Attending trade shows like Canton Fair provides invaluable face-to-face supplier assessment opportunities, allowing you to evaluate products firsthand and arrange factory visits.

- Proper due diligence requires verifying business licenses, ISO certifications, and conducting factory audits to confirm production capabilities and quality control processes.

- Building long-term relationships depends on clear communication (using visual aids and WeChat), culturally sensitive interactions, and structured contracts with detailed quality specifications.

- Protect yourself from scams by watching for red flags like unusually low prices, upfront payment demands, and reluctance to provide video tours, while safeguarding intellectual property with NDAs and strategic production compartmentalization.

Looking to expand your business with products from China but worried about finding trustworthy suppliers? You're not alone. The Chinese market offers incredible manufacturing opportunities at competitive prices, but navigating this vast landscape can be challenging without the right approach.

Finding reliable suppliers in China requires strategic research, proper vetting, and understanding cultural business practices. With counterfeits and scams potentially lurking, it's crucial to know exactly how to identify legitimate manufacturers who'll deliver quality products on time. The good news? With the right methods, you can build profitable, long-term relationships with dependable Chinese suppliers.

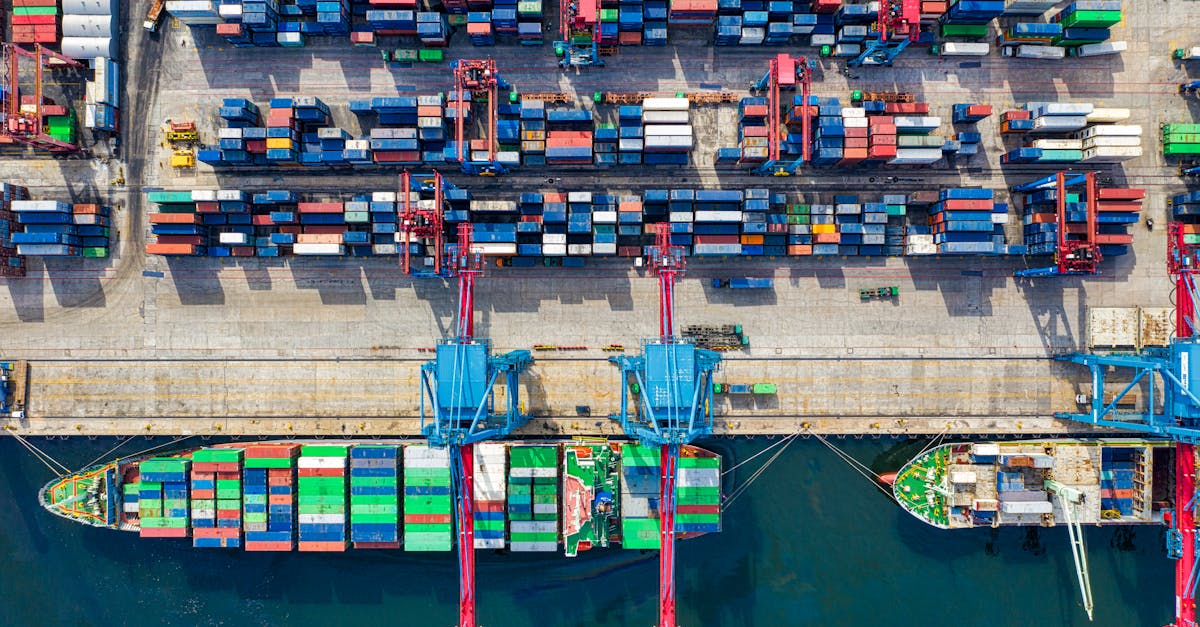

The Growing Importance of Chinese Suppliers in Global Trade

China's manufacturing sector has transformed global trade dynamics over the past three decades. Chinese suppliers now account for 28.7% of global manufacturing output, making China the world's largest producer of manufactured goods. This dominance stems from several key advantages Chinese manufacturers offer to international businesses.

Chinese suppliers provide remarkable cost efficiencies through lower labor costs, economies of scale, and advanced manufacturing infrastructure. A typical electronics product manufactured in China costs 20-30% less than producing the same item in Western countries, creating significant margin opportunities for importers.

The manufacturing capabilities in China span virtually every industry—from textiles and electronics to heavy machinery and pharmaceuticals. Major manufacturing hubs like Shenzhen specialize in electronics, while Guangzhou excels in textiles and Hangzhou dominates in furniture production. This specialization creates ecosystems where suppliers develop deep expertise in specific product categories.

China's infrastructure advantages further strengthen its position in global trade. The country has invested over $1.3 trillion in transportation networks since 2008, building 25,000 miles of high-speed rail and expanding its shipping capacity with seven of the world's ten busiest ports. This infrastructure enables efficient movement of goods from factories to global markets.

For businesses entering international markets, Chinese suppliers offer a practical entry point with low minimum order quantities (MOQs) and flexible production capabilities. Many manufacturers accept initial orders of just 500-1,000 units compared to the 5,000+ units often required by manufacturers in other regions.

The digital transformation of China's manufacturing sector has also accelerated global connectivity. E-commerce platforms like Alibaba, Global Sources, and Made-in-China now connect over 40 million businesses worldwide with Chinese suppliers, eliminating traditional barriers to international sourcing.

Key Challenges When Sourcing From China

While Chinese manufacturing offers significant advantages, several common obstacles can complicate the sourcing process. Understanding these challenges helps you develop effective strategies to overcome them and establish successful supplier relationships.

Language and Cultural Barriers

Communication difficulties present immediate hurdles when sourcing from China. Many Chinese suppliers have limited English proficiency, which leads to misinterpretations of product specifications, shipping terms, or quality requirements. Cultural differences in business etiquette further complicate relationships—Chinese business culture emphasizes building relationships (guanxi) before transactions, values indirect communication, and approaches negotiations differently than Western practices. Business hours and holidays, like Chinese New Year (when factories close for 2-4 weeks), create operational gaps that require advance planning. Using translation tools, hiring bilingual sourcing agents, or working with suppliers who employ English-speaking staff helps bridge these communication gaps.

Quality Control Concerns

Product quality inconsistency remains one of the most significant challenges when working with Chinese manufacturers. Production standards vary dramatically between suppliers, with some cutting corners on materials or processes to reduce costs. Without proper oversight, you might receive initial samples of excellent quality followed by substandard bulk production. The distance between you and your supplier complicates immediate inspection and correction of issues. Implementing a structured quality control system with detailed product specifications, regular third-party inspections (pre-production, during production, and pre-shipment), and clearly defined acceptance criteria protects your product standards. Many businesses employ local quality inspectors or sourcing companies that perform on-site factory audits to verify manufacturing capabilities and quality management systems.

Legitimate Business Verification

Identifying legitimate suppliers among thousands of options poses a significant challenge. China's manufacturing sector includes established factories, trading companies posing as manufacturers, and occasional fraudulent operations. Without proper verification, you risk paying deposits to non-existent companies or receiving counterfeit products. Business credentials like business licenses, export licenses, and tax registration certificates provide basic verification but require authentication. Third-party verification services, such as supplier audits by quality control companies or background checks through platforms like Alibaba's Trade Assurance, add security layers. Requesting manufacturing facility videos, client references, or product samples allows you to assess capabilities before committing to larger orders. Physical factory visits remain the gold standard for verification, though they require significant investment in time and travel expenses.

Online Platforms for Finding Chinese Suppliers

Online platforms have transformed how businesses connect with Chinese manufacturers, offering access to thousands of verified suppliers. These digital marketplaces provide tools to evaluate, compare, and contact potential partners directly while minimizing traditional sourcing barriers.

Alibaba and Global Sources

Alibaba stands as China's largest B2B platform with over 40 million active buyers connecting to millions of suppliers. The platform offers Trade Assurance protection on qualified orders, safeguarding your payments up to 100% if suppliers fail to meet agreed terms. Alibaba's verification system includes Verified Suppliers, Trade Assurance providers, and Gold Suppliers—companies that undergo third-party verification and pay membership fees, indicating established business operations.

Global Sources serves as a premium alternative focusing on higher-quality manufacturers and exporters. It differentiates itself by conducting more rigorous supplier verification including factory audits and placing greater emphasis on export-ready businesses. Global Sources' specialized trade shows in Hong Kong provide opportunities to meet suppliers face-to-face, complementing online sourcing efforts with direct relationship-building opportunities.

Made-in-China and DHgate

Made-in-China targets businesses seeking industrial and manufacturing suppliers with over 3 million products across 27 major categories. Their verification system offers three distinct reliability levels: Audited Supplier, Assessed Supplier, and Authentication Supplier—each providing different levels of verification depth. Their standout feature includes virtual factory tours, allowing you to inspect facilities remotely before committing to partnerships.

DHgate specializes in smaller wholesale orders with lower minimum order quantities, making it ideal for small businesses or test orders. The platform hosts over 2.2 million sellers offering consumer goods across 148 product categories. DHgate's buyer protection includes escrow payments, shipping insurance, and return policies that reduce risk for first-time importers or those placing smaller orders.

WeChat and Chinese Social Media

WeChat functions as more than a messaging app—it's an essential business networking tool used by over 1.2 billion Chinese users, including manufacturers and suppliers. Many factories maintain official WeChat accounts where they showcase products, production capabilities, and certifications unavailable on traditional B2B platforms. WeChat's translation feature automatically converts messages between Chinese and English, helping overcome language barriers.

Chinese industry-specific forums like 1688.com (Alibaba's domestic platform) provide access to manufacturers who primarily serve the local market at potentially lower prices. While these platforms typically operate in Chinese, integration with translation tools makes them increasingly accessible. Xiaohongshu (Little Red Book) and Douyin (Chinese TikTok) showcase trending products and emerging manufacturers, offering insights into China's domestic market trends and helping identify suppliers creating innovative products before they reach international markets.

Attending Trade Shows and Sourcing Events

Trade shows and sourcing events offer unparalleled opportunities to connect with Chinese suppliers in person, allowing you to evaluate products firsthand and build stronger business relationships. These events bring together thousands of manufacturers under one roof, creating efficient environments for comparing options and conducting initial negotiations.

Canton Fair and Other Major Exhibitions

The Canton Fair (China Import and Export Fair) stands as China's largest and most prestigious trade show, attracting over 25,000 exhibitors and 200,000 buyers across its biannual sessions in Guangzhou. This massive exhibition spans three phases, covering electronics, household items, textiles, and machinery in separate segments. Other significant trade shows include:

- Global Sources Exhibitions: Held in Hong Kong, these events focus on consumer electronics, gifts, home products, and fashion accessories with strict supplier verification.

- East China Fair: Located in Shanghai, this fair specializes in textiles, garments, and household products with 4,000+ exhibitors.

- Yiwu Fair: Centered in Zhejiang Province, this event showcases over 100,000 consumer products from 4,500+ booths, particularly strong in small commodities.

- China Beauty Expo: The largest beauty industry event in Asia with 3,500+ exhibitors displaying cosmetics, packaging, and beauty equipment.

Industry-specific exhibitions like CHINAPLAS for plastics and rubber or Shanghai Furniture Fair provide targeted sourcing opportunities within your vertical market, featuring specialized suppliers not commonly found on online platforms.

Making the Most of Face-to-Face Meetings

Face-to-face interactions create valuable opportunities to assess suppliers beyond their product offerings. Prepare thoroughly by:

- Setting clear objectives: Create a list of 10-15 specific questions about minimum order quantities, production capacity, and quality control processes.

- Bringing product samples: Carry competitor products or prototypes to demonstrate exactly what you're looking for, eliminating confusion.

- Taking detailed notes: Document conversations with suppliers using a standardized template that tracks key capabilities, pricing structures, and impression scores.

- Collecting comprehensive materials: Gather business cards, product catalogs, and price sheets from each supplier for post-event evaluation.

- Scheduling factory visits: Arrange on-site visits to production facilities of promising suppliers while you're already in China, saving additional travel expenses.

The in-person assessment allows you to evaluate suppliers' English proficiency, responsiveness, and cultural compatibility—factors that significantly impact long-term business relationships. Look for representatives who ask thoughtful questions about your business and demonstrate genuine interest in establishing partnership rather than securing one-time sales.

Exchange WeChat contacts with promising suppliers for immediate follow-up, as this platform serves as the primary business communication tool in China. After the event, send personalized messages within 48 hours referencing specific conversation points to maintain momentum in relationship building.

Working With Sourcing Agents and Intermediaries

Sourcing agents and intermediaries serve as valuable partners when navigating China's complex manufacturing landscape. These professionals bridge cultural and language gaps while leveraging established networks to streamline your supplier search process.

Benefits and Drawbacks of Using Agents

Sourcing agents offer significant advantages for businesses new to the Chinese market. They provide immediate access to pre-vetted supplier networks, eliminating weeks of research and verification. Their language fluency resolves communication barriers, reducing misunderstandings on specifications and terms. Local agents handle on-the-ground quality inspections, saving international travel costs while ensuring consistent production standards.

Despite these benefits, working with agents presents certain challenges. Sourcing agents typically charge 5-10% commission fees on orders, impacting your profit margins. Their involvement creates an additional layer between you and manufacturers, potentially slowing direct relationship development. You'll also face dependency risks if the agent controls all supplier relationships, leaving your business vulnerable if the partnership ends.

Many sourcing agents specialize in specific industries—electronics, textiles, or consumer goods—providing deeper expertise but limiting cross-category flexibility. Their service quality varies dramatically, from full-service partners managing everything from sourcing to logistics to basic matchmaking services with minimal follow-through.

How to Select a Reputable Sourcing Partner

Finding a trustworthy sourcing agent requires thorough vetting and clear expectations. Start by requesting detailed case studies and client references from potential agents, contacting at least 3-5 previous clients to verify their experience. Examine their industry specialization, ensuring they have 2+ years working with products similar to yours.

Transparency in fee structures distinguishes professional agents from opportunistic intermediaries. Reputable agents offer clear commission models (fixed fee, percentage-based, or hybrid) without hidden costs. Establish detailed service expectations through formal contracts covering responsibilities, deliverables, quality control procedures, and communication protocols.

Communication capabilities serve as crucial indicators of agent effectiveness. Test responsiveness by tracking how quickly they address inquiries and how thoroughly they answer technical questions. Professional agents maintain regular reporting schedules with factory updates, quality control findings, and production timelines.

Consider location-based advantages when selecting partners. Agents based in manufacturing hubs like Shenzhen for electronics or Guangzhou for consumer goods offer stronger local networks and more frequent factory access. Cross-verify agent credentials through business registrations and professional associations like the China Sourcing Agents Association, which maintains certification standards for member organizations.

Conducting Due Diligence on Potential Suppliers

Proper due diligence separates successful sourcing ventures from costly mistakes when working with Chinese suppliers. Thorough verification processes help you identify legitimate partners and reduce risks associated with overseas manufacturing relationships.

Verification of Business Licenses and Certifications

Legitimate Chinese suppliers maintain several key business documents that confirm their legal status and manufacturing capabilities. Request the supplier's business license (营业执照 - Yíngyè Zhízhào), which contains their registration number, business scope, and registered capital—all indicators of company size and stability. Verify this information through China's National Enterprise Credit Information Publicity System, accessible online at gsxt.gov.cn. Additionally, check for ISO certifications (ISO 9001, ISO 14001), product-specific certifications (CE, UL, FDA), and export licenses that demonstrate their compliance with international standards and ability to legally ship products overseas. Reputable suppliers readily provide these documents and welcome verification requests as part of normal business practice.

Factory Audits and Site Visits

Factory visits provide invaluable firsthand insights impossible to gather through digital communication alone. When conducting an on-site audit, examine production capacity by counting equipment and workers to verify the supplier's claimed manufacturing capabilities. Assess quality control procedures by observing testing methods, inspection points, and how defects are handled during production. Document your observations with photos (where permitted) of manufacturing areas, inventory storage, and finished product samples. If personal visits aren't feasible, hire third-party inspection services like SGS, Bureau Veritas, or TÜV to conduct professional audits using standardized evaluation criteria. These audits typically cost $500-$1,500 depending on factory size and assessment depth, providing detailed reports on facilities, management systems, and production practices with an objective compliance score.

Building Long-Term Relationships With Chinese Suppliers

Establishing enduring partnerships with Chinese suppliers requires consistent effort and cultural understanding beyond the initial sourcing process. These relationships form the foundation of reliable supply chains and can lead to preferential treatment, better pricing, and higher quality products over time.

Communication Strategies That Work

Effective communication bridges cultural gaps and strengthens supplier relationships in China's business environment. Regular video calls create personal connections that text-based communication can't match, while keeping conversations direct and focused respects your supplier's time. Learning basic Mandarin phrases demonstrates respect and commitment, even if you rely on translators for complex discussions.

When sending specifications or requirements, use visual aids like photos, diagrams, and videos to overcome language barriers. Confirm understanding by asking suppliers to repeat requirements back to you or provide samples before full production. Many Chinese businesses use WeChat as their primary communication tool, making it essential to establish a presence on this platform for quick responses and relationship building.

Cultural sensitivity matters significantly—avoid scheduling meetings during Chinese holidays like Chinese New Year when factories typically close for weeks. When facing challenges, approach conversations with patience and focus on solutions rather than placing blame, as this collaborative approach aligns with Chinese business culture's emphasis on harmony.

Payment Terms and Contract Considerations

Negotiating favorable payment terms represents a critical aspect of building sustainable supplier relationships while protecting your business interests. Initial orders typically require deposits of 30-50%, with remaining payments due upon production completion, though these terms become more flexible as trust develops. Consider using Alibaba Trade Assurance or letters of credit for larger transactions to add security layers to your payments.

Contracts must address delivery timelines, quality standards, and intellectual property protections clearly to prevent misunderstandings. Include detailed product specifications with acceptable tolerance ranges and quality control procedures that outline inspection methods and rejection criteria. Establish consequences for missed deadlines or quality issues, such as discounts or expedited shipping at the supplier's expense.

Price adjustment mechanisms deserve careful attention in long-term contracts, especially for raw material-intensive products. Create formulas that account for market fluctuations rather than fixed pricing that could strain the relationship during sudden cost increases. OEM agreements should explicitly cover intellectual property ownership, prohibiting unauthorized reproduction or sales of your products to competitors.

During contract negotiations, remain firm on critical requirements while showing flexibility on less important terms—this balanced approach demonstrates good faith while protecting your core business needs. Having contracts reviewed by lawyers familiar with Chinese business law ensures your agreements are enforceable within China's legal framework, providing additional security for your long-term supplier relationships.

Avoiding Common Scams and Pitfalls

Sourcing from China offers tremendous opportunities but comes with inherent risks. Knowledge of common scams and warning signs helps you navigate the market confidently while protecting your business interests.

Red Flags to Watch For

Red flags signal potential supplier issues before you commit resources or capital. Watch for suppliers who resist video calls or factory tours, as legitimate manufacturers have nothing to hide and gladly showcase their facilities. Be wary of unusually low prices that undercut market rates by 30-40%, as these often indicate substandard materials or hidden fees later. Question suppliers who request full payment upfront with no escrow options, especially for first-time orders. Examine communication patterns closely—professional suppliers respond promptly with detailed answers, while scammers provide vague information and dodge specific questions. Verify business emails match company domains rather than free services like Gmail or Hotmail, which legitimate enterprises rarely use for business transactions.

Protecting Your Intellectual Property

Intellectual property protection requires proactive measures when manufacturing in China. Sign comprehensive Non-Disclosure Agreements (NDAs) before sharing product designs or specifications, ensuring they're enforceable under Chinese law. Consider filing for patents, trademarks, or copyrights directly in China, as international registrations offer limited protection in the Chinese market. Implement strategic information compartmentalization by dividing production components among multiple suppliers so no single manufacturer has complete product knowledge. Use digital watermarks and identification codes on product designs to track unauthorized reproductions. Establish regular monitoring systems to detect counterfeit versions of your products in online marketplaces like Taobao or Alibaba. Partner with legal firms specializing in Chinese IP law to quickly address violations through cease-and-desist measures or formal legal channels when necessary.

Conclusion

Finding reliable suppliers in China requires diligence thorough research and cultural awareness but the rewards are substantial. By leveraging online platforms trade shows and professional sourcing agents while conducting proper due diligence you'll significantly reduce risks and identify trustworthy partners.

Remember that successful sourcing from China isn't just about finding suppliers—it's about building relationships. Invest time in clear communication protect your intellectual property and remain vigilant against common scams.

With China's manufacturing dominance continuing to grow establishing strong supplier partnerships now positions your business for long-term success. The journey requires patience but with the strategies outlined in this guide you're well-equipped to navigate China's vast manufacturing landscape confidently and profitably.

Frequently Asked Questions

What percentage of global manufacturing output does China account for?

China accounts for 28.7% of global manufacturing output, making it the world's largest producer of manufactured goods. This dominant position in global trade makes Chinese suppliers increasingly important for businesses looking to expand their product offerings at competitive prices.

How can I verify if a Chinese supplier is legitimate?

Verify Chinese suppliers by checking their business licenses and certifications, conducting factory audits or site visits, and using third-party verification services. Request documentation like business licenses, ISO certifications, and export licenses. Consider hiring professional inspection services if you cannot visit personally. Always verify multiple contact points.

What are the main challenges when sourcing from China?

The main challenges include language and cultural barriers leading to miscommunication, quality control concerns requiring structured oversight, verifying legitimate suppliers among numerous options, and navigating different business practices. Understanding Chinese business etiquette and building relationships are essential for overcoming these challenges.

Which online platforms are best for finding Chinese suppliers?

The top platforms include Alibaba (offering Trade Assurance protection), Global Sources (known for rigorous verification), Made-in-China, and DHgate. Each platform has different strengths and verification levels. Additionally, WeChat and Chinese social media platforms can be valuable for networking and product showcasing.

Are trade shows worth attending to find Chinese suppliers?

Yes, trade shows are extremely valuable for meeting suppliers face-to-face, evaluating products firsthand, and building stronger relationships. Major events like the Canton Fair, Global Sources Exhibitions, and East China Fair connect you with thousands of manufacturers. These interactions help assess communication skills and cultural compatibility.

Should I use a sourcing agent when dealing with Chinese manufacturers?

Sourcing agents can be valuable partners, offering pre-vetted supplier networks and local expertise to navigate China's manufacturing landscape. However, consider potential drawbacks like commission fees and dependency risks. When selecting an agent, thoroughly vet their reputation, ensure clear communication, and establish transparent fee structures.

What payment terms are safest when working with Chinese suppliers?

The safest approach is using staged payments, such as 30% deposit and 70% upon completion. Avoid paying 100% upfront. Use secure payment methods like bank transfers or letters of credit for large orders. Escrow services provided by platforms like Alibaba offer additional protection by holding funds until delivery conditions are met.

How can I protect my intellectual property when sourcing from China?

Protect your IP by signing Non-Disclosure Agreements (NDAs), filing for patents and trademarks in China (not just your home country), compartmentalizing production processes among different suppliers, and implementing monitoring systems to detect counterfeits. Work with legal experts familiar with Chinese intellectual property law.

What are common scams to watch out for when sourcing from China?

Watch for suppliers who resist video calls or factory tours, offer unusually low prices, request full payment upfront, have unprofessional communication, or show inconsistencies in company information. Be cautious of suppliers unwilling to sign contracts or those pushing for wire transfers to personal accounts. Always conduct thorough due diligence.

How important is cultural understanding when working with Chinese suppliers?

Cultural understanding is crucial for successful long-term relationships. Recognize the importance of face (mianzi), build personal connections (guanxi), respect hierarchy, and understand indirect communication styles. Patience in negotiations, appreciation of Chinese holidays, and small gestures of goodwill significantly impact business relationships.