Navigating the complex regulations for hazardous materials shipping in the Middle East requires specialized knowledge and careful planning. From chemical substances to flammable liquids, the transportation of dangerous goods across this region's diverse regulatory landscape presents unique challenges for logistics professionals and businesses alike.

When you're shipping hazardous materials through Middle Eastern ports and borders, you'll need to comply with both international standards and local requirements that vary significantly between countries. The Gulf Cooperation Council (GCC) members, including Saudi Arabia and the UAE, have implemented stringent protocols that align with the United Nations' Globally Harmonized System of Classification and Labeling of Chemicals (GHS), while maintaining their own specific documentation requirements and handling procedures.

Understanding Hazardous Materials Classifications in Middle East Shipping

Hazardous materials classifications form the foundation of safe shipping practices across the Middle East. These classification systems provide standardized frameworks for identifying, labeling, and handling dangerous goods during transportation through various Middle Eastern ports and transportation networks.

IMO and UN Classification Standards

The International Maritime Organization (IMO) and United Nations (UN) classification systems serve as the primary frameworks for hazardous materials shipping in the Middle East. The UN system divides dangerous goods into nine distinct classes based on their primary hazard: explosives, gases, flammable liquids, flammable solids, oxidizing substances, toxic substances, radioactive materials, corrosives, and miscellaneous dangerous goods. These classifications appear on all shipping documentation, including the Dangerous Goods Declaration (DGD) and Material Safety Data Sheets (MSDS). Middle Eastern countries like Saudi Arabia, UAE, and Qatar strictly enforce these standards at their maritime ports, with specialized inspectors examining cargo manifests to verify proper classification and documentation compliance.

Regional Variations in Classification Systems

Despite adhering to international standards, Middle Eastern countries maintain significant regional variations in hazardous materials classification systems. Saudi Arabia implements additional sub-classifications for petroleum-derived chemicals that account for desert transportation conditions. The UAE employs a traffic-light rating system (red, amber, green) as a supplementary layer to the UN classifications, determining port handling priorities and storage requirements. Qatar and Kuwait have developed specialized classifications for chemicals used in natural gas production and refinement. Egypt maintains unique classifications for hazardous materials transported through the Suez Canal, with stricter requirements for vessels carrying Class 1 (explosives) and Class 7 (radioactive) materials. Navigating these regional variations requires collaboration with local freight forwarders who maintain updated classification guides specific to each country's requirements and recent regulatory changes.

Regulatory Framework Governing Hazardous Materials in the Middle East

The Middle East's regulatory landscape for hazardous materials shipping combines international standards with region-specific requirements. This dual framework creates a complex compliance environment that requires specialized knowledge and careful navigation by shippers and logistics providers operating throughout the region.

GCC Unified Hazardous Materials Regulations

The Gulf Cooperation Council (GCC) has established unified regulations for hazardous materials transport that serve as a foundation for member states. These regulations align with the UN's Globally Harmonized System (GHS) while addressing regional considerations specific to the Arabian Peninsula. Key components of the GCC framework include:

- Technical Regulations for Handling of Chemicals - Standardized protocols for storage, transport, and handling of chemicals across all GCC nations

- Classification System Alignment - Harmonization with international standards while incorporating regional risk factors such as extreme heat conditions

- Unified Electronic Tracking System - Mandatory real-time tracking for Class 1 (explosives) and Class 7 (radioactive) materials crossing GCC borders

- Hazardous Waste Transportation Guidelines - Specific procedures for cross-border movement of hazardous waste materials between GCC states

The GCC Technical Committee for Hazardous Materials meets quarterly to update these regulations, ensuring they reflect current international best practices while addressing regional security and environmental concerns.

Country-Specific Compliance Requirements

Despite GCC harmonization efforts, individual Middle Eastern countries maintain specific regulatory requirements that shippers must address:

Saudi Arabia:

- Requires SASO (Saudi Standards, Metrology and Quality Organization) certification for all hazardous materials

- Implements additional clearance procedures through the High Commission for Industrial Security

- Mandates use of Arabic language on all hazardous materials documentation

- Enforces stricter regulations for materials transported to religious sites in Mecca and Medina

United Arab Emirates:

- Operates through a decentralized system where each emirate has distinct requirements

- Requires Electronic Dangerous Goods Declaration (e-DGD) for all hazardous shipments

- Implements extra security measures at Jebel Ali Port for Class 1 and 2 materials

- Mandates Environmental Impact Assessments for Class 8 (corrosive) and Class 9 (miscellaneous) hazardous goods

Qatar:

- Enforces the Qatar Hazardous Materials Management System (QHMMS) for all dangerous goods

- Requires pre-approval from the Ministry of Municipality and Environment

- Implements specialized regulations for materials serving the LNG industry

- Mandates quarterly reporting of all hazardous materials inventories within the country

Egypt:

- Maintains separate regulatory frameworks for hazardous materials passing through the Suez Canal

- Requires submission of Material Safety Data Sheets (MSDS) 72 hours before arrival

- Implements additional inspections for Class 5 (oxidizing substances) and Class 6 (toxic substances)

- Follows modified versions of ADR regulations (European Agreement concerning the International Carriage of Dangerous Goods by Road)

Working with logistics partners experienced in navigating these country-specific requirements helps ensure compliance and prevents costly delays in Middle East hazardous materials shipping operations.

Best Practices for Packaging and Labeling Hazardous Cargo

Proper packaging and labeling are crucial elements in the safe transportation of hazardous materials across Middle Eastern countries. Implementation of these practices ensures compliance with both international standards and region-specific regulations while minimizing the risk of incidents during transit.

Temperature-Controlled Solutions for Extreme Desert Conditions

Temperature control represents a critical challenge when shipping hazardous materials through the Middle East's harsh desert environment. Temperatures regularly exceed 50°C (122°F) in summer months across countries like Saudi Arabia, UAE, and Kuwait, potentially causing chemical instability in reactive substances. Specialized thermal packaging solutions include vacuum-insulated panels that maintain internal temperatures 30-40°C below ambient conditions for up to 120 hours. Triple-layer thermal blankets reflect 95% of solar radiation, protecting cargo during airport tarmac delays, which commonly last 3-4 hours during peak seasons.

For highly sensitive materials, active cooling containers equipped with solar-powered backup systems ensure temperature integrity even during power failures. These systems maintain temperatures within ±2°C of specified ranges and include 24/7 remote monitoring capabilities with SMS alerts for temperature deviations. When shipping through Jebel Ali Port or King Abdullah Port, selecting temperature-controlled zones reduces exposure risks by 75% compared to standard storage areas.

Documentation and Marking Requirements

Documentation and marking compliance for hazardous cargo in the Middle East involves specific regional protocols beyond international standards. All hazardous shipments require a minimum of four essential documents: material safety data sheets (MSDS), dangerous goods declarations (DGD), certificates of origin, and customs clearance forms. In Saudi Arabia, SASO certification must accompany these documents, while the UAE mandates Electronic Dangerous Goods Declarations submitted 24 hours before arrival.

Marking requirements include GHS-compliant hazard pictograms placed on at least two opposing sides of packages, with each symbol measuring 100mm × 100mm minimum for packages over 30kg. UN packaging certification codes must appear in Arabic and English on all primary containers, with a required font size of 12mm height. GCC countries require unique tracking barcodes linked to their unified electronic tracking system, positioned on the upper right corner of each package. Temperature-sensitive materials must display exposure indicators that change color when exposed to temperatures outside safe ranges.

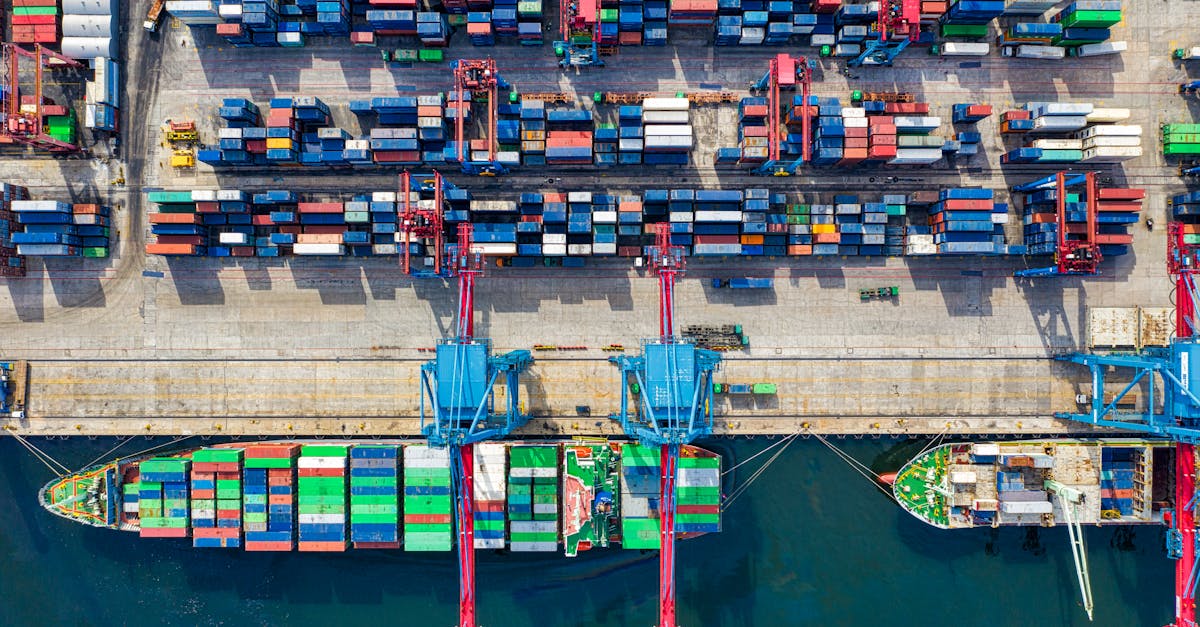

Port Infrastructure for Handling Dangerous Goods

Middle Eastern ports have developed specialized infrastructure to safely manage hazardous materials throughout the supply chain. These dedicated facilities incorporate advanced safety systems, specialized storage solutions, and comprehensive emergency response capabilities to mitigate risks associated with dangerous cargo handling.

Specialized Storage Facilities in Major Middle Eastern Ports

Middle Eastern ports feature purpose-built storage facilities designed specifically for dangerous goods compliance and safety. Jebel Ali Port in Dubai houses 35 dedicated dangerous goods warehouses with segregated storage zones for each hazard class, climate-controlled chambers for temperature-sensitive materials, and vapor extraction systems for volatile compounds. Similarly, King Abdullah Port in Saudi Arabia offers 28,000 square meters of specialized chemical storage facilities equipped with explosion-proof electrical systems, containment berms, and automated fire suppression.

Key specialized storage features across major regional ports include:

- Segregation systems that physically separate incompatible hazardous materials using reinforced concrete barriers and designated safe distances

- Temperature-controlled environments maintaining optimal conditions between 15-25°C for reactive chemicals despite exterior temperatures exceeding 45°C

- Spill containment infrastructure including chemical-resistant flooring, containment sumps, and specialized drainage systems connected to treatment facilities

- Automated monitoring using IoT sensors tracking temperature, pressure, gas levels, and structural integrity with real-time alerts

- Restricted access zones implementing biometric security, specialized training requirements, and continuous CCTV surveillance

These facilities adhere to International Maritime Dangerous Goods (IMDG) Code requirements while incorporating additional regional safeguards like enhanced seismic protection at Oman's Sohar Port and radiation monitoring equipment at Qatar's Hamad Port.

Emergency Response Capabilities at Key Shipping Hubs

Middle Eastern ports maintain comprehensive emergency response systems designed for immediate hazardous material incident management. The Khalifa Port in Abu Dhabi features a 24/7 emergency response team comprising 42 specialized hazmat technicians equipped with Level A protective equipment and capable of responding within 3 minutes to any terminal location.

Critical emergency response capabilities across the region include:

- On-site HAZMAT teams trained in chemical, biological, and radiological incident management with regular drills conducted quarterly

- Specialized equipment fleets including foam fire trucks, portable decontamination stations, and unmanned containment vehicles for high-risk scenarios

- Advanced detection systems utilizing infrared imaging, chemical analyzers, and remote monitoring drones to assess incidents safely

- Tiered response protocols with clearly defined escalation procedures connecting port resources with municipal fire departments and national emergency management agencies

- Containment infrastructure featuring isolated drainage systems, emergency retention ponds, and deployable floating barriers for port-water contamination control

Saudi Arabia's King Fahd Industrial Port demonstrates regional best practices through its integrated emergency management center, which coordinates responses with neighboring chemical facilities and maintains mutual aid agreements with six regional response organizations. Additionally, Aqaba Port in Jordan conducts monthly joint exercises with customs, environmental agencies, and medical services to ensure seamless coordination during hazardous material events.

Transportation Challenges in the Region

Shipping hazardous materials across the Middle East presents unique transportation challenges that require specialized solutions and strategic planning. These challenges stem from the region's distinct geography, climate conditions, and security landscape that directly impact the safe movement of dangerous goods.

Maritime Security Concerns When Shipping Hazardous Materials

Maritime security represents a critical concern when transporting hazardous materials through Middle Eastern waterways. The strategic chokepoints like the Strait of Hormuz and Bab el-Mandeb experience ongoing geopolitical tensions that introduce unpredictable risk factors for hazardous cargo vessels. Pirates operate in specific zones along the Gulf of Aden and the Red Sea, targeting commercial shipping with 27 attempted attacks reported in 2022 alone. International naval coalitions patrol these high-risk areas, providing escorts for vessels carrying dangerous goods through designated Maritime Security Transit Corridors (MSTC).

Shipping companies transporting hazardous materials must implement enhanced security protocols including:

- Reinforced vessel communication systems with 24/7 monitoring capabilities

- Anti-piracy physical barriers such as razor wire and water cannons

- Crews trained in security procedures specific to hazardous cargo defense

- Real-time threat intelligence subscription services for route planning

Port facilities throughout the region have upgraded their security infrastructure with radiation detection equipment, specialized CCTV systems, and restricted access zones for hazardous material handling areas. Compliance with the International Ship and Port Facility Security (ISPS) Code is strictly enforced, with additional regional security requirements imposed at major ports in Saudi Arabia, UAE, and Oman.

Intermodal Transport Considerations

Intermodal transport of hazardous materials in the Middle East requires coordinated planning across multiple transportation methods and specialized infrastructure. Rail networks remain limited compared to other regions, with only 8,500 kilometers of operational track across GCC countries, creating heavy reliance on road transportation for inland distribution. This limitation creates significant challenges when transporting temperature-sensitive chemicals across vast desert terrains.

Key intermodal challenges include:

- Temperature fluctuations ranging from -5°C at night to 50°C during summer days

- Limited specialized hazmat trucking fleets with proper certifications

- Border crossing complexities with varying documentation requirements

- Inadequate dangerous goods handling facilities at smaller inland terminals

Recent infrastructure investments have improved the situation with specialized cross-border corridors between Saudi Arabia and the UAE featuring hazmat-certified inspection points and emergency response stations every 75 kilometers. The new Etihad Rail network incorporates UN-standard hazardous materials handling capabilities at its intermodal terminals, including segregated storage areas and specialized transfer equipment.

Companies shipping hazardous materials through the region must develop comprehensive intermodal transit plans that account for these infrastructure variations. Partnering with logistics providers who maintain specialized equipment like temperature-controlled ISO tank containers and GPS-equipped vehicles with hazmat tracking systems ensures safer transitions between transportation modes in this challenging environment.

Training and Certification Requirements for Personnel

Personnel handling hazardous materials in Middle East shipping operations must undergo rigorous training and certification to ensure compliance with both international and regional regulations. The complex regulatory environment in the region necessitates specialized knowledge and qualifications for anyone involved in the transport, storage, or handling of dangerous goods.

Mandatory Safety Programs for Handlers

Middle Eastern countries implement comprehensive safety programs that all hazardous materials handlers must complete. These programs include specialized HAZMAT awareness training, chemical exposure prevention techniques, and emergency response procedures tailored to regional risks. In Saudi Arabia, the High Commission for Industrial Security mandates the 40-hour Basic Operator Training program for all personnel handling Class 1-9 dangerous goods. UAE's Federal Authority for Nuclear Regulation requires handlers to complete the 5-day Hazardous Materials Management certification, which must be renewed every 3 years. Workers in Qatar must participate in the Qatar Petroleum Safety Training program, which incorporates modules specific to natural gas-related chemicals.

These mandatory programs emphasize practical skills through hands-on exercises and realistic simulations of common regional hazards like chemical spills in high-temperature environments. Training facilities in Dubai, Riyadh, and Doha feature specialized equipment that replicates port and transportation conditions, giving handlers experience with the exact situations they'll encounter on the job.

International vs. Local Certification Standards

The Middle East's approach to hazardous materials certification combines international standards with region-specific requirements. International certifications like IMDG Code training certificates, IATA Dangerous Goods Regulations qualifications, and UN Model Regulations compliance credentials serve as the foundation for handler qualifications. These global standards establish baseline competencies recognized across the shipping industry.

Regional certifications add another layer of requirements tailored to Middle Eastern conditions. The GCC Unified Hazardous Materials Handling certification program incorporates elements addressing extreme heat management and specific cultural considerations in emergency communications. Saudi Arabia's MOMRA (Ministry of Municipal and Rural Affairs) certification focuses on desert transportation challenges, while the UAE's OSHAD system requires specialized training for handling hazardous materials in humid coastal environments.

The certification landscape features notable differences between countries. Kuwait mandates the Kuwaiti Institute of Scientific Research (KISR) hazmat handling certificate for petroleum-derived chemicals. Bahrain's HIPME (Hazardous Industries Protocol for Middle East) certification includes modules on managing chemical reactions in high salinity environments. Jordan requires the Royal Scientific Society's HAZMAT handling attestation, which includes training on cross-border documentation procedures.

Companies operating across multiple Middle Eastern countries address these varying requirements by developing comprehensive training matrices that map each employee's certifications against country-specific needs. Leading logistics firms maintain training centers in regional hubs like Dubai and Riyadh where handlers receive both international standard training and country-specific certification preparation, creating a workforce qualified to handle hazardous materials throughout the Middle East shipping network.

Risk Management Strategies for Middle East Shipping Routes

Risk management forms the cornerstone of hazardous materials shipping across Middle Eastern routes, requiring comprehensive approaches tailored to the region's unique challenges. Successful risk mitigation balances regulatory compliance with operational flexibility while addressing the distinctive hazards of desert climates and geopolitical complexities.

Insurance Considerations for Hazardous Cargo

Insurance coverage for hazardous materials shipping in the Middle East requires specialized policies that address regional risks and regulatory requirements. Standard marine cargo insurance typically excludes or severely limits coverage for dangerous goods, making specialized hazardous materials coverage essential. Leading insurers like AXA Gulf and Zurich Middle East offer tailored policies with higher premiums that reflect the elevated risk profiles.

Key insurance components for Middle East hazardous cargo include:

- Environmental liability coverage - Protects against cleanup costs and third-party damage claims resulting from accidental releases

- Extended transit coverage - Accounts for longer holding periods at customs checkpoints common in GCC countries

- Political risk insurance - Covers losses due to regional conflicts, sanctions changes, or government seizures

- Temperature deviation coverage - Specifically addresses cargo degradation from exposure to extreme desert temperatures

Insurance requirements vary significantly across Middle Eastern countries. Saudi Arabia mandates minimum coverage of $2 million for Class 1-3 materials, while the UAE requires electronic verification of insurance certificates through their Smart Services portal. Qatar's Civil Defense Authority conducts regular audits of insurance documentation for hazardous shipments entering the country.

Working with insurance brokers specializing in Middle Eastern markets provides crucial advantages for securing appropriate coverage. These specialists maintain relationships with local authorities and understand certification requirements that vary by port and material classification.

Contingency Planning for Transit Disruptions

Effective contingency planning for hazardous materials shipping in the Middle East anticipates potential disruptions and establishes clear response protocols. Regional shipping routes face unique vulnerabilities including seasonal sandstorms, checkpoint delays, and occasional port closures due to geopolitical tensions.

A comprehensive contingency plan includes:

- Alternative routing options - Mapping secondary shipping lanes and ports of entry for each destination country

- Temporary storage arrangements - Pre-identifying certified hazardous materials storage facilities at strategic points along shipping routes

- Communication protocols - Establishing clear communication channels with local authorities, carriers, and emergency responders

- Material-specific response procedures - Developing detailed protocols for each hazard class that align with both UN guidelines and local requirements

Forward-positioned emergency equipment caches at key transit points enhance response capabilities. Companies like Maersk and DP World maintain specialized hazmat response equipment at major regional ports including Jebel Ali and King Abdullah Port.

Real-time monitoring systems provide crucial early warning capabilities for Middle East shipping operations. Advanced tracking technologies integrate satellite monitoring with environmental sensors to detect issues before they escalate. The GCC's unified electronic tracking system requires transmitters on Class 1, 2, and 7 shipments, sending alerts to relevant authorities if environmental parameters exceed safe thresholds.

Supply chain resilience strategies must account for the Middle East's unique seasonal patterns. The extreme summer heat (May-September) necessitates additional contingency measures for temperature-sensitive materials, while religious observances like Ramadan affect customs processing times and staffing levels at ports throughout the region.

Environmental Impact and Sustainability Concerns

Shipping hazardous materials through the Middle East presents significant environmental challenges in one of the world's most ecologically sensitive regions. The combination of busy shipping lanes, fragile marine ecosystems, and limited natural freshwater resources amplifies the potential consequences of improper handling or accidental releases of dangerous goods.

Pollution Prevention Measures in Sensitive Waterways

Middle Eastern waterways require specialized pollution prevention protocols due to their ecological significance and vulnerability. The Persian Gulf, Red Sea, and Mediterranean contain delicate coral reef systems and endangered marine species that face heightened risk from chemical contaminants. Key pollution prevention measures implemented across regional shipping routes include:

- Double-hull requirements for all vessels carrying hazardous liquids, exceeding international MARPOL standards by 15% in thickness specifications

- Advanced ballast water treatment systems that filter and neutralize potentially contaminated water before discharge

- Designated shipping lanes that keep hazardous cargo vessels at least 50 nautical miles from protected marine habitats

- Real-time monitoring networks with sensors detecting chemical leaks at 12 strategic checkpoints throughout major shipping corridors

- Zero-discharge zones around sensitive areas like Bahrain's pearl beds and Qatar's mangrove forests where no operational discharges are permitted

The Maritime Environmental Protection Committee for the Gulf States (MEPCGS) conducts quarterly water quality assessments and has established rapid-response pollution containment teams at five strategic points along major shipping routes. These teams can deploy within 30 minutes of a reported incident and contain specialized equipment for different classes of hazardous materials.

Waste Management Protocols at Ports

Middle Eastern ports have developed comprehensive hazardous waste management systems that address the unique challenges of handling dangerous cargo residues in environmentally responsible ways. These protocols incorporate both international standards and region-specific requirements:

| Port | Waste Processing Capacity | Specialized Treatment Facilities | Recycling Rate |

|---|---|---|---|

| Jebel Ali (UAE) | 2,500 tons/day | Chemical neutralization, thermal desorption | 64% |

| King Abdullah (KSA) | 1,800 tons/day | Solvent recovery, solidification | 58% |

| Hamad Port (Qatar) | 1,200 tons/day | Mercury reclamation, acid treatment | 52% |

| Shuwaikh (Kuwait) | 950 tons/day | Oil-water separation, bioremediation | 46% |

Port waste management protocols include:

- Mandatory pre-arrival waste declarations submitted electronically 72 hours before vessel arrival

- Segregated collection systems with 9 different waste streams for various hazardous material classes

- On-site treatment facilities capable of neutralizing reactive chemicals before final disposal

- Circular economy initiatives recovering 52-64% of chemical packaging materials for reprocessing

- Electronic tracking systems following waste from collection through treatment to final disposal

The Jebel Ali Green Port Initiative exemplifies advanced practices with its closed-loop chemical waste processing facility that treats 1,500 tons of hazardous packaging daily. Similarly, Saudi Arabia's King Abdullah Port operates a zero-landfill policy for all hazardous materials residues, with thermal treatment and material recovery processes handling 100% of chemical waste.

These environmental protection measures represent significant investments by Middle Eastern countries to balance economic development with sustainability concerns. For shippers, compliance with these regulations isn't just about avoiding penalties—it's about participating in the region's commitment to preserving its fragile natural ecosystems while facilitating essential trade in hazardous materials.

Key Takeaways

- Shipping hazardous materials in the Middle East requires compliance with both international standards (UN/IMO classifications) and country-specific regulations that vary significantly across the region.

- The Gulf Cooperation Council (GCC) has established unified hazardous materials regulations, though individual countries like Saudi Arabia, UAE, and Qatar maintain additional requirements including specialized documentation and certifications.

- Middle Eastern ports have developed specialized infrastructure for dangerous goods, including temperature-controlled storage facilities designed for extreme desert conditions and comprehensive emergency response capabilities.

- Personnel handling hazardous materials must complete rigorous training programs and obtain both international and local certifications, which vary by country and material classification.

- Maritime security represents a critical concern when transporting hazardous materials through strategic waterways like the Strait of Hormuz, requiring enhanced security protocols and monitoring systems.

- Environmental protection measures are increasingly stringent across Middle Eastern shipping routes, with specialized pollution prevention protocols for sensitive waterways and comprehensive waste management systems at major ports.

Conclusion

Shipping hazardous materials across the Middle East requires a strategic approach that combines technical expertise with regional knowledge. You'll need to navigate the complex web of GCC regulations while accounting for each country's specific requirements.

Working with experienced logistics partners is essential for managing the unique challenges of extreme temperatures specialized port infrastructure and security concerns. Your success depends on proper documentation detailed contingency planning and comprehensive insurance coverage tailored to regional risks.

By investing in certified personnel adopting proper packaging standards and staying current with regulatory changes you'll minimize risks while ensuring efficient operations. The key to successful hazardous materials shipping in this dynamic region lies in balancing international standards with local compliance requirements.

Remember that environmental protection measures aren't just regulatory obligations but critical components of responsible business practices in the Middle East's sensitive ecosystems.