Key Takeaways

- Dropshipping fulfillment is a four-stage process that includes receiving customer orders, processing orders with suppliers, shipping and tracking, and final delivery confirmation—all without handling inventory yourself.

- Selecting reliable suppliers is crucial for success, with key considerations including fulfillment accuracy rates, geographic location, MOQ requirements, sample ordering options, and return policy flexibility.

- Technology solutions like Order Management Systems (OMS) and inventory synchronization tools can reduce processing times by 60-75% and decrease out-of-stock issues by 40-50% compared to manual methods.

- Common challenges include inventory discrepancies and shipping delays, which can be mitigated through real-time inventory management systems and diversifying supplier networks across different regions.

- Tracking key performance indicators (KPIs) such as order fulfillment rate, accuracy rate, processing time, and shipping time is essential for measuring success and identifying areas for improvement.

- Continuous improvement methods like PDCA cycles, root cause analysis, supplier scorecards, and regular fulfillment audits help create an adaptive operation that meets evolving customer expectations.

Thinking about launching a dropshipping business but feeling overwhelmed by the fulfillment process? You're not alone. The dropshipping order fulfillment journey can seem complex at first glance, but breaking it down into manageable steps makes it far less daunting.

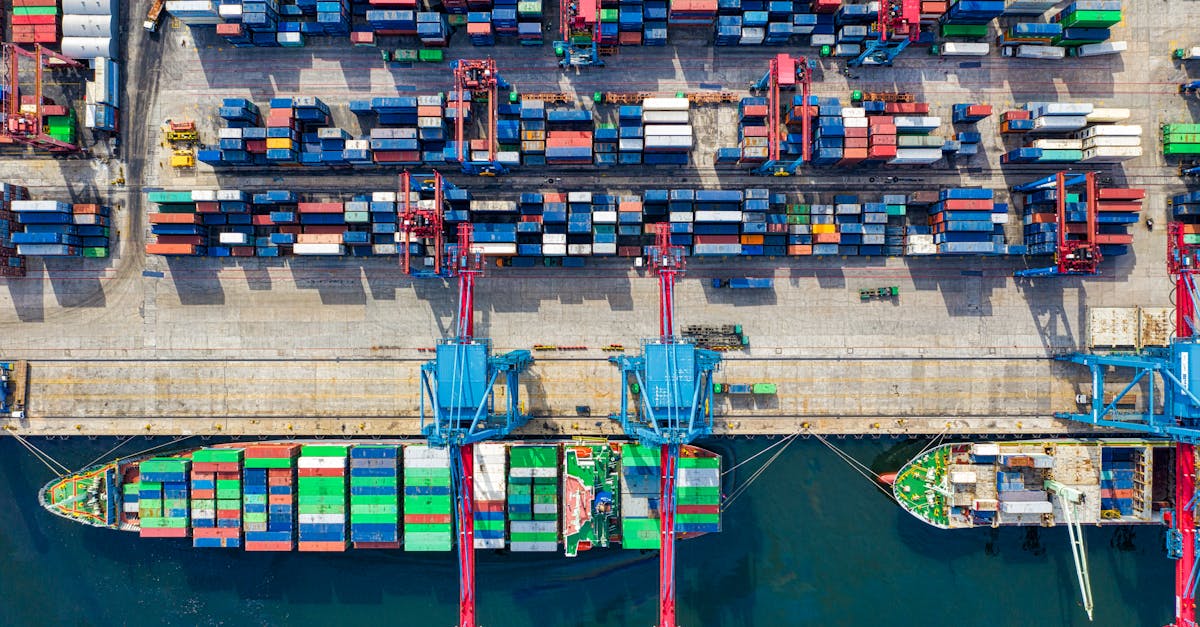

At its core, dropshipping fulfillment is the series of actions that take place from the moment a customer places an order to when they receive their package. Unlike traditional retail, you'll never handle inventory yourself—instead, your suppliers ship products directly to your customers. This streamlined approach has made dropshipping an attractive business model for entrepreneurs looking to start with minimal investment and overhead costs.

What Is Dropshipping and How Does It Work

Dropshipping is an e-commerce business model where you sell products without maintaining inventory, manufacturing items, or shipping packages. Instead, when a customer purchases from your online store, you purchase the item from a third-party supplier who ships it directly to the customer. You're essentially the middleman between the supplier and the customer, focusing on marketing and customer service rather than inventory management.

The Step-by-Step Dropshipping Process

The dropshipping fulfillment process follows a straightforward sequence:

- Store setup - You create an online store and list products sourced from suppliers

- Customer ordering - A customer visits your store and places an order

- Order forwarding - You forward the order details to your supplier

- Supplier processing - The supplier prepares and packages the product

- Direct shipping - The supplier ships the product directly to your customer

- Order tracking - You and your customer receive tracking information

- Customer receipt - The customer receives their package with your branding

During this entire process, you never physically handle the products. Your supplier manages inventory storage, packaging, and shipping logistics while you focus on marketing, customer acquisition, and growing your business.

Benefits of the Dropshipping Model

Dropshipping offers several key advantages for e-commerce entrepreneurs:

- Low startup costs - Launch a business without investing in inventory

- Reduced overhead - Eliminate warehousing expenses and inventory management

- Location independence - Run your business from anywhere with internet access

- Flexible product testing - Test new products without bulk purchases

- Scalability - Add new products or expand to new markets without logistical constraints

- Time efficiency - Focus on marketing and business growth rather than fulfillment tasks

These benefits make dropshipping particularly attractive for new entrepreneurs, side-hustlers, and established businesses looking to expand their product lines with minimal risk.

The Complete Dropshipping Order Fulfillment Process

The dropshipping order fulfillment process consists of four critical stages that transform a customer's purchase into a delivered package. Understanding each phase helps streamline operations and ensures customers receive their orders promptly and accurately.

Receiving Customer Orders

Customer orders arrive through your online store's checkout system, triggering the fulfillment workflow. Your e-commerce platform automatically captures essential order details including customer information, shipping address, payment confirmation, and product specifications. Most platforms like Shopify, WooCommerce, or BigCommerce notify you of new orders via email or dashboard alerts, allowing you to review the orders before processing. Setting up automated order confirmation emails reassures customers their purchase was successful and provides estimated delivery timeframes.

Processing Orders With Suppliers

Once you've received customer orders, you'll forward them to your dropshipping supplier for fulfillment. This stage involves submitting purchase orders containing product details, quantities, and customer shipping information to your supplier through their preferred channel—such as supplier portals, email, or API integration. Automated order processing systems like Oberlo, DSers, or Spocket connect your store directly to suppliers, reducing manual data entry and minimizing errors. After submitting orders, confirm receipt from your supplier and verify stock availability to prevent backorder situations that might delay delivery.

Order Shipping and Tracking

After your supplier processes the order, they'll ship the product and provide tracking information. Most suppliers send tracking numbers within 1-3 business days after receiving the order, which you'll need to forward to your customers. Implementing automated tracking updates through your e-commerce platform keeps customers informed about their package status without requiring manual intervention. Monitor shipping progress closely to identify potential delays or issues, enabling proactive communication with customers when problems arise.

Customer Delivery and Confirmation

The final stage culminates when customers receive their orders and you confirm successful delivery. Tracking systems automatically mark orders as "delivered" based on carrier confirmation, creating a record of completed transactions. Sending post-delivery follow-up emails 2-3 days after confirmed delivery encourages customers to share feedback about their experience and product satisfaction. This stage also involves managing any delivery exceptions like failed deliveries, damaged packages, or missing items through your established return and exchange policies.

Key Technologies for Efficient Dropshipping Fulfillment

Modern technology solutions streamline the dropshipping fulfillment process, reducing manual work and minimizing errors. These digital tools automate crucial aspects of order management, inventory tracking, and communication between all parties involved in the supply chain.

Order Management Systems

Order management systems (OMS) form the backbone of efficient dropshipping operations by centralizing order processing in one platform. These systems capture customer orders from multiple sales channels, automatically route them to appropriate suppliers, and track fulfillment status in real-time. Popular OMS options like Orderhive, Linnworks, and Oberlo offer features such as bulk order processing, automated supplier notifications, and customizable workflows. E-commerce entrepreneurs using these systems report processing times reduced by 60-75% compared to manual methods. OMS platforms also provide crucial analytics on order volume, fulfillment speed, and supplier performance to help identify bottlenecks and optimization opportunities.

Inventory Synchronization Tools

Inventory synchronization tools eliminate the risk of selling out-of-stock items by maintaining real-time connections between your store and supplier inventories. These platforms automatically update product availability across multiple sales channels when supplier stock levels change, preventing overselling situations that lead to cancellations and negative reviews. Advanced synchronization tools like Syncee, Inventory Source, and DSers refresh inventory data at intervals as short as 30 minutes and send alerts when items reach critical stock levels. Integration capabilities with popular e-commerce platforms such as Shopify, WooCommerce, and Amazon ensure seamless data flow between systems. Dropshippers using these tools typically experience 40-50% fewer out-of-stock issues and customer service inquiries related to availability problems.

Common Challenges in Dropshipping Order Fulfillment

Dropshipping businesses face several operational hurdles that can impact customer satisfaction and business reputation. Despite the advantages of the dropshipping model, certain challenges require strategic solutions to maintain efficient order fulfillment processes.

Inventory Discrepancies

Inventory discrepancies create significant obstacles in dropshipping operations when supplier stock levels don't match your online store listings. These inconsistencies typically occur due to outdated inventory feeds, delayed synchronization between systems, or suppliers failing to communicate stock changes promptly. For example, your store might show 50 units available while the supplier actually has only 5 units in stock, leading to backorders and disappointed customers.

To combat inventory discrepancies, implement real-time inventory management systems that connect directly with supplier databases. Use automation tools that update product availability every 15-30 minutes rather than once daily. Establish clear communication protocols with suppliers, including requirements for immediate notification of low stock items or manufacturing delays. Consider working with multiple suppliers for popular products to create inventory redundancy, reducing the risk of complete stockouts.

Shipping Delays and Solutions

Shipping delays represent one of the most common customer complaints in dropshipping, directly impacting satisfaction and retention rates. These delays stem from multiple factors including supplier processing backlogs, international shipping complications, customs delays, and carrier capacity issues during peak seasons. For instance, orders shipped from China to the US typically take 12-20 days, but can extend to 30+ days during holiday periods.

Mitigate shipping delays by diversifying your supplier network across different geographic regions, reducing delivery distances to major customer bases. Partner with suppliers offering expedited shipping options that customers can select during checkout. Implement order tracking systems providing customers with real-time package location updates and realistic delivery estimates. Create proactive communication workflows that automatically notify customers about potential delays before they inquire. During peak seasons like Black Friday or Christmas, adjust your website's shipping time expectations and consider temporarily removing products from suppliers with known fulfillment issues.

Optimizing Your Dropshipping Fulfillment Strategy

Optimizing your dropshipping fulfillment strategy transforms average operations into exceptional customer experiences. Fine-tuning your processes eliminates inefficiencies, reduces costs, and increases customer satisfaction.

Selecting Reliable Suppliers

Reliable suppliers form the backbone of successful dropshipping operations. Evaluate potential partners based on product quality, shipping times, and communication responsiveness before integration into your supply chain. Look for suppliers with proven track records in your niche, verified by positive reviews from other dropshippers and consistently delivered high-quality products.

Consider these key factors when selecting suppliers:

- Fulfillment accuracy rates of at least 99% to minimize order errors

- Geographic location relative to your target market to reduce shipping times

- MOQ requirements that align with your business volume and cash flow

- Sample ordering options to verify product quality firsthand

- Return policy flexibility to handle customer dissatisfaction effectively

Create a supplier scorecard to objectively compare potential partners across these criteria. Test multiple suppliers with small orders before committing to larger volumes, giving priority to those who demonstrate consistency in their operations and transparent communication about potential issues.

Streamlining Communication Channels

Streamlined communication channels prevent costly misunderstandings and expedite order processing between you, suppliers, and customers. Implement centralized communication systems that integrate with your order management platform for maximum efficiency.

Effective communication optimization includes:

- Automated order notifications that instantly alert suppliers to new orders

- Standardized templates for routine communications about shipping updates

- Integrated messaging platforms that consolidate supplier conversations

- Clear escalation protocols for addressing urgent fulfillment issues

- Multi-channel customer service options including email, chat, and social media

Set clear communication expectations with suppliers, including response time requirements (ideally within 24 hours) and regular performance review meetings. Create a shared terminology glossary to eliminate confusion about shipping terms, product specifications, and service level agreements.

Implement status update triggers at key fulfillment stages—order receipt, processing, shipping, and delivery—to keep customers informed without manual intervention. This proactive approach reduces customer service inquiries by approximately 25% while building trust in your brand's reliability.

Measuring Success in Dropshipping Order Fulfillment

Effective measurement of your dropshipping order fulfillment performance provides critical insights that drive business growth and customer satisfaction. Tracking specific metrics and implementing improvement processes transforms raw data into actionable strategies that optimize your operations.

Important KPIs to Track

Key Performance Indicators (KPIs) serve as vital benchmarks for evaluating your dropshipping fulfillment effectiveness. These quantifiable metrics reveal operational strengths and weaknesses across your fulfillment process:

- Order Fulfillment Rate: The percentage of orders successfully fulfilled compared to total orders received. A rate above 95% indicates strong operational performance.

- Order Accuracy Rate: Measures orders delivered without errors in products, quantity, or specifications. Top-performing dropshippers maintain accuracy rates of 98% or higher.

- Processing Time: The average time between receiving an order and forwarding it to your supplier. Industry standards suggest keeping this under 24 hours.

- Supplier Performance: Tracks how consistently suppliers meet expectations for stock availability, processing speed, and product quality.

- Shipping Time: The average duration from order dispatch to customer delivery, segmented by shipping regions and methods.

- Return Rate: The percentage of products returned due to damage, incorrect items, or quality issues. The industry average ranges from 8-10% for most e-commerce categories.

- Customer Satisfaction Score (CSAT): Collected through post-purchase surveys, this metric quantifies customer experience with your fulfillment process.

- Cost Per Order: The total operational expense divided by the number of orders processed, helping identify cost-efficiency opportunities.

Track these metrics using integrated analytics dashboards in your order management system to spot trends and address issues proactively.

Continuous Improvement Methods

Implementing systematic improvement approaches transforms your dropshipping fulfillment from reactive to proactive:

- PDCA Cycle: Apply the Plan-Do-Check-Act methodology to test fulfillment improvements in controlled phases before full implementation. For example, test a new supplier communication protocol with a small product segment before expanding company-wide.

- Root Cause Analysis: Investigate recurring issues by examining the underlying causes rather than symptoms. If late deliveries consistently affect certain regions, analyze specific carrier performance data for those areas.

- A/B Testing: Compare different fulfillment strategies side-by-side to determine superior approaches. Test various packaging methods or shipping carriers with similar customer segments to identify optimal choices.

- Supplier Scorecards: Develop comprehensive evaluation systems that grade suppliers on multiple performance dimensions including accuracy, timeliness, and communication responsiveness.

- Customer Feedback Integration: Create structured processes for collecting and analyzing customer comments about delivery experiences to identify improvement priorities.

- Benchmarking: Compare your fulfillment metrics against industry standards and competitors to identify performance gaps and opportunities.

- Process Mapping: Document your complete fulfillment workflow to identify redundant steps and bottlenecks that delay order processing.

- Regular Fulfillment Audits: Conduct quarterly reviews of your entire fulfillment process, focusing on automation opportunities and error patterns.

By consistently applying these improvement methods, you'll create a fulfillment operation that adapts to changing market conditions and evolving customer expectations, strengthening your competitive advantage in the dropshipping marketplace.

Conclusion

Mastering the dropshipping order fulfillment process is essential for your e-commerce success. By implementing reliable supplier relationships automated order management systems and inventory synchronization tools you'll create a seamless customer experience while minimizing operational headaches.

Remember to track your KPIs consistently measure supplier performance and actively seek customer feedback. These practices will help you identify bottlenecks adapt to market changes and continuously improve your fulfillment strategy.

With the right systems in place dropshipping offers a flexible low-investment business model that can scale with your ambitions. As you refine your fulfillment processes you'll build customer trust increase satisfaction and develop a competitive edge in the dynamic world of e-commerce.

Frequently Asked Questions

What is dropshipping?

Dropshipping is an e-commerce business model where sellers act as intermediaries between customers and suppliers. The key distinction is that dropshippers don't maintain inventory or handle shipping directly. Instead, when a customer places an order, the seller purchases the item from a supplier who ships it directly to the customer. This model requires minimal upfront investment and allows entrepreneurs to run businesses without managing physical inventory.

How does the dropshipping fulfillment process work?

The dropshipping fulfillment process involves four main stages: receiving customer orders through your online store, processing those orders with suppliers, tracking shipments, and confirming customer delivery. When a customer places an order, you forward it to your supplier who picks, packs, and ships the product directly to your customer. You're responsible for managing the customer relationship throughout the process, though you never physically handle the products.

What are the main benefits of dropshipping?

Dropshipping offers several key advantages: low startup costs with minimal inventory investment, reduced overhead expenses, location independence (work from anywhere), flexible product testing without large inventory commitments, easy scalability, and time efficiency. These benefits make dropshipping particularly attractive for new entrepreneurs, side-hustlers, and established businesses looking to expand their product offerings with minimal risk.

What technologies can improve dropshipping fulfillment?

Two critical technologies for efficient dropshipping are Order Management Systems (OMS) and inventory synchronization tools. An OMS centralizes order processing from multiple sales channels, automates order routing, and provides real-time tracking. Inventory synchronization tools maintain accurate connections between your store and supplier inventories, preventing overselling by automatically updating product availability and alerting you to low stock levels.

What are common challenges in dropshipping fulfillment?

The major challenges include inventory discrepancies (when supplier stock doesn't match your store listings) and shipping delays. Inventory issues often stem from outdated feeds or poor communication, while shipping delays can result from supplier backlogs, international shipping complications, or customs issues. These challenges can significantly impact customer satisfaction and your business reputation if not properly managed.

How can I select reliable dropshipping suppliers?

Select suppliers based on fulfillment accuracy, geographic proximity to your target market, production capacity, communication responsiveness, and return policy flexibility. Create a supplier scorecard to objectively compare options, and always test potential suppliers with small orders before making larger commitments. Reliable suppliers are crucial to maintaining customer satisfaction and your business reputation.

What metrics should I track to measure dropshipping success?

Track these key performance indicators: order fulfillment rate, order accuracy rate, processing time, supplier performance, shipping time, return rate, customer satisfaction score, and cost per order. Use integrated analytics dashboards to monitor these metrics consistently. Regular analysis of these KPIs will help identify operational strengths and weaknesses, allowing you to make data-driven improvements to your dropshipping business.

How can I handle shipping delays in dropshipping?

To manage shipping delays effectively, diversify your supplier network to reduce dependency on a single source, offer expedited shipping options for customers willing to pay for faster delivery, and maintain proactive communication about potential delays. Set realistic delivery expectations upfront, and when delays occur, notify customers immediately with updated timeframes and perhaps offer compensation like discount codes.